What is Mecanizado de precisión ? Definición y principios clave

Definición de Mecanizado de precisión y su importancia en la fabricación moderna

La mecanización de precisión se refiere a un método de fabricación subtractivo en el que se utilizan máquinas CNC controladas por computadora para fabricar piezas con tolerancias extremadamente ajustadas, a veces hasta más o menos 0.005 pulgadas. Cuando entra en juego el software CAD CAM, básicamente convierte esos planos digitales en trayectorias de corte precisas que permiten una exactitud a nivel de micrones. La importancia de este tipo de precisión no puede ser exagerada, especialmente en sectores como la ingeniería aeroespacial o la producción de dispositivos médicos. Una sola inconsistencia en estas piezas puede significar consecuencias serias tanto para la seguridad como para el desempeño general. Mirando hacia el futuro, analistas del mercado predicen que la industria mundial de mecanización de precisión crecerá significativamente, alcanzando aproximadamente 180.25 mil millones de dólares para el año 2030 con una tasa anual de crecimiento de alrededor del 7.8 por ciento. Esta expansión parece estar impulsada en gran medida por las necesidades crecientes de sectores como el desarrollo avanzado de robótica y el impulso hacia soluciones de energía renovable en varias industrias.

¿ Cómo? Mecanizado de precisión Difiere de los Métodos de Mecanizado Convencionales

El mecanizado tradicional depende en gran medida del trabajo manual y normalmente alcanza niveles de tolerancia de ±0.01 pulgadas. El mecanizado de precisión adopta un enfoque completamente diferente. Con sistemas CNC que se encargan desde la selección de herramientas hasta el ajuste automático de velocidades de corte y posicionamiento de piezas, estas máquinas pueden alcanzar una precisión de ±0.001 pulgadas una y otra vez. Piénselo de esta manera: los fabricantes ahora pueden producir lotes de 10,000 tornillos médicos en los que cada uno mide dentro de apenas 5 micras de perfección. Las técnicas manuales simplemente no pueden mantener tal consistencia más allá de quizás 100 piezas como máximo. Los números también respaldan esto. Según una investigación del NIST en 2023, los procesos automatizados reducen los errores humanos en aproximadamente dos tercios. Esto hace posible fabricar a gran escala todo tipo de formas complejas, algo casi imposible utilizando únicamente métodos tradicionales.

El Papel de las Tolerancias y el Acabado Superficial en la Definición de la Precisión

Cuando hablamos de fabricación de precisión, las tolerancias y la rugosidad superficial (Ra) nos dicen realmente lo que necesitamos saber. Por ejemplo, en el caso de las palas de turbinas aerospaciales, estas requieren especificaciones extremadamente ajustadas, alrededor de ±0.0002 pulgadas, y un acabado superficial de aproximadamente 0.4 micrómetros para soportar condiciones operativas tan exigentes. Si las piezas se salen del rango de tolerancia de 0.01 pulgadas, estudios de la Society of Manufacturing Engineers muestran que las tasas de fallo aumentan casi un 20%, lo que significa que algunos fabricantes pierden cerca de setecientos cuarenta mil dólares al año solo por estos problemas. Por otro lado, cuando las superficies son más suaves en el rango de Ra 0.8 a 1.6 micrómetros, hay menos fricción en los sistemas hidráulicos. Esto también mejora su funcionamiento, aumentando la eficiencia energética en alrededor del 15 por ciento. Todos estos números apuntan a una sola cosa: la precisión importa mucho al construir equipos que deben operar bajo presión.

El papel de la tecnología CNC en la consecución de precisión

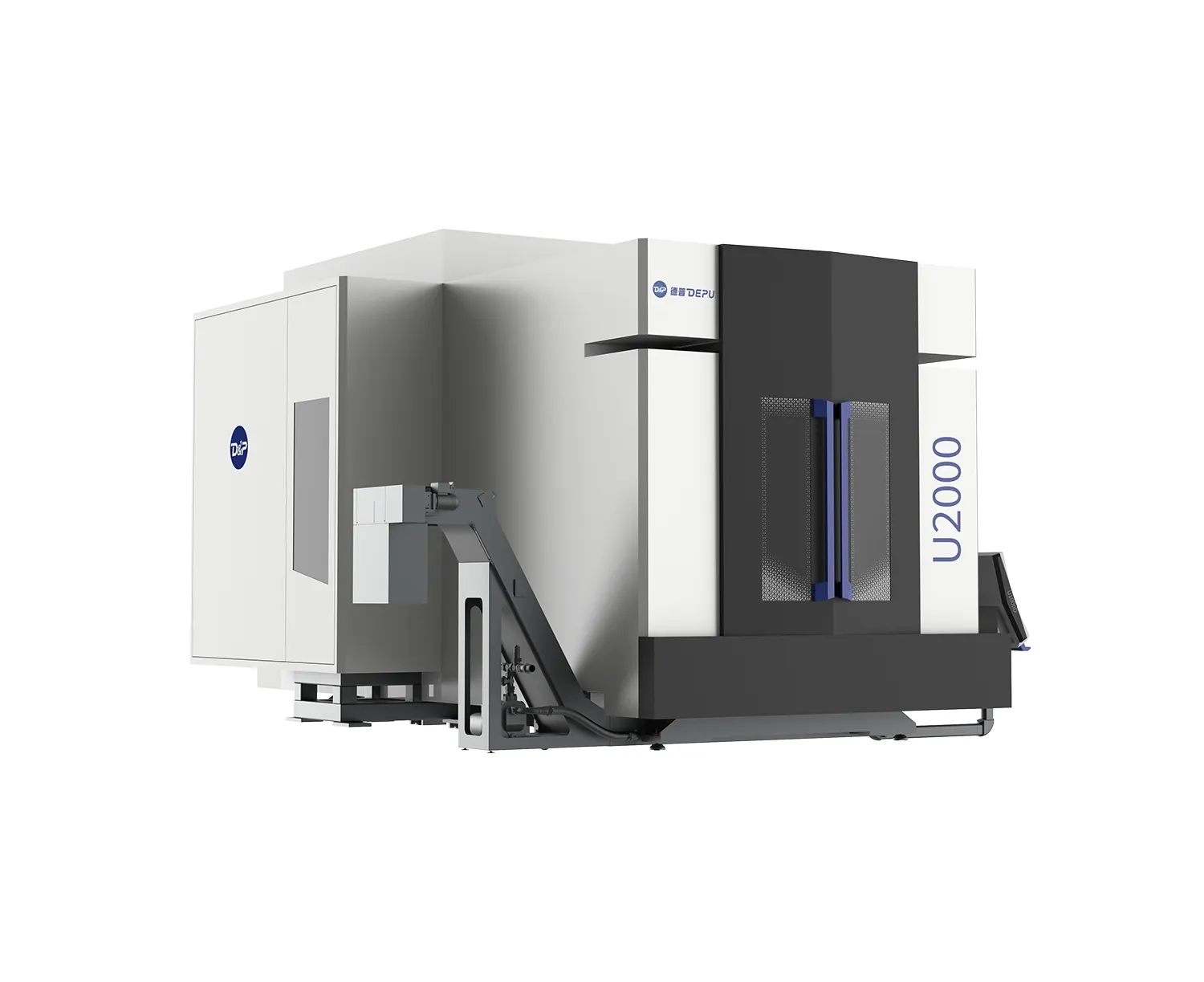

Introducción al mecanizado y fresado CNC en la fabricación de precisión

La tecnología CNC, que significa Control Numérico por Computadora, constituye la base de la industria moderna de mecanizado preciso. El sistema toma esos diseños digitales realizados en computadoras y los convierte en rutas reales que las herramientas de corte deben seguir durante la fabricación. Lo que hace tan impresionante al CNC es su capacidad para controlar dimensiones con una precisión extrema, a veces tan ajustadas como más o menos 0,005 milímetros. Piense en industrias donde estas pequeñas medidas realmente importan. En ingeniería aeroespacial, por ejemplo, equivocarse en un solo decimal podría significar un desastre cuando las piezas no encajan correctamente. De manera similar, en la fabricación de dispositivos médicos, errores mínimos podrían provocar implantes que simplemente no funcionen correctamente dentro del cuerpo humano. Por eso, los fabricantes de estos sectores críticos dependen en gran medida de las máquinas CNC día a día.

Cómo los sistemas CNC mejoran la precisión, repetibilidad y eficiencia

Las máquinas CNC utilizan sistemas de retroalimentación en bucle cerrado para monitorear y corregir la posición de las herramientas en tiempo real. Según un estudio de 2023 publicado en el Journal of Manufacturing Systems , los sistemas CNC avanzados reducen los errores dimensionales en un 63 % en comparación con los métodos tradicionales. Entre las ventajas clave se incluyen:

- Repetibilidad : Los procesos automatizados garantizan una conformidad del 99,8 % en grandes series de producción (Ponemon 2023).

- Coordinación multieje : El mecanizado de 5 ejes permite producir formas complejas en una sola configuración, reduciendo los plazos de entrega en un 40 %.

Evolución de la tecnología CNC y su impacto en la producción industrial

Desde la década de 1950, la tecnología de control numérico por computadora ha pasado por importantes transformaciones, alejándose de los antiguos sistemas de tarjetas perforadas hasta llegar a lo que vemos hoy en día, con la ayuda de la inteligencia artificial durante los procesos de mecanizado. Los equipos modernos vienen equipados con sensores del Internet de las Cosas que vigilan las vibraciones en tiempo real y también se ajustan ante cambios de temperatura. Estos sensores realmente corrigen pequeños problemas con una precisión de aproximadamente más o menos 2 micrones cuando las condiciones a su alrededor cambian. Las mejoras logradas con el tiempo han impulsado significativamente el avance en los círculos de fabricación. Tomemos como ejemplo los semiconductores: las empresas buscan superficies extremadamente suaves cuyo promedio de rugosidad sea inferior a 0,1 micrómetros Ra. Alcanzar este nivel requiere actualmente de configuraciones de CNC de primera calidad.

Paradoja Industrial: Alto Costo Inicial frente a Precisión y Retorno de Inversión a Largo Plazo

Invertir en máquinas CNC implica un desembolso inicial considerable, normalmente entre 150 mil y 500 mil dólares, pero el dinero se amortiza con el tiempo. Estas máquinas reducen los materiales desperdiciados en un 23 por ciento aproximadamente, lo cual se suma rápidamente. Además, también aceleran la llegada de los productos al mercado, reduciendo cerca del 34 por ciento el tiempo necesario para fabricar piezas de alta precisión. Los números respaldan esto también. Talleres de tamaño mediano reportan ahorros de aproximadamente 740 mil dólares al año solo en control de calidad después de cambiar a la tecnología CNC. Tiene sentido cuando se considera todo junto, tanto desde el punto de vista económico como por la fluidez en las operaciones diarias.

La Mecanizado de precisión Flujo de trabajo: desde el diseño CAD hasta la inspección final

Fase de diseño utilizando software CAD en flujos de trabajo de fabricación

El proceso comienza con software CAD (Diseño Asistido por Computadora), donde los ingenieros crean modelos 3D con dimensiones exactas y especificaciones de tolerancia a nivel microscópico, a menudo tan precisas como ±0.001 mm. Este enfoque digital elimina los errores de dibujo manual y reduce el desperdicio de material hasta un 50 % en comparación con los métodos tradicionales de diseño.

Programación CAM y Generación de Trayectorias de Herramienta para Ejecución CNC

Tras finalizar el modelo CAD, el software CAM (Fabricación Asistida por Computadora) genera código G legible para la máquina que define las trayectorias de herramienta, velocidades del husillo y tasas de avance. Los sistemas CAM avanzados simulan toda la secuencia de mecanizado para detectar colisiones y optimizar los tiempos de ciclo, fundamental para mantener la eficiencia en producción de alto volumen.

Configuración de Máquina, Selección de Material y Sujeción de la Pieza

Al elegir materiales para trabajos de mecanizado, los operadores suelen optar por materiales como aluminio de grado aeroespacial o acero inoxidable de grado médico, ya que necesitan ciertas propiedades para la tarea en cuestión. Para evitar que la materia prima se mueva durante la ejecución a altas velocidades, las empresas suelen fijarla con mordazas hidráulicas, mordazas estándar o incluso mesas de vacío, dependiendo de lo que mejor funcione para el material. Conseguir buenos resultados depende en gran medida de mantener todo estable, ya que cualquier vibración puede estropear las medidas y dejar superficies rugosas que nadie desea. Y no olvides calibrar adecuadamente las herramientas antes de comenzar el trabajo. Una empresa que visité la semana pasada calibraba todas sus máquinas CNC semanalmente solo para mantener cortes consistentes en distintos proyectos.

Ejecución del Mecanizado y Monitoreo en Tiempo Real

Durante la ejecución, las máquinas CNC siguen instrucciones programadas mientras sensores integrados monitorean la temperatura, vibración y desgaste de las herramientas. Los sistemas de bucle cerrado ajustan dinámicamente los parámetros, por ejemplo, compensando la deflexión de las herramientas en cavidades profundas, reduciendo las tasas de desecho en un 30–40 % en comparación con procesos no monitoreados.

Postprocesamiento, Inspección y Garantía de Calidad

Después del mecanizado, las piezas pasan por etapas de postprocesamiento como desbarbado, pulido o anodizado. La inspección final implica el uso de MCM (Máquinas de Medición por Coordenadas) para verificar las dimensiones respecto al modelo CAD original y perfilómetros de superficie para medir la rugosidad hasta 0,1 µm. Gráficos de control estadístico del proceso rastrean las variaciones, asegurando un cumplimiento del 99,9 % con las normas ISO 9001 antes de la entrega.

Núcleo Mecanizado de precisión Técnicas y Sus Aplicaciones

CNC fresado: Principios, aplicaciones y precisión dimensional

El mecanizado CNC funciona utilizando herramientas de corte rotativas controladas por computadora para eliminar material de las piezas de trabajo. La precisión puede llegar a ser realmente impresionante, a veces hasta una tolerancia de solo 0.001 pulgada según estándares de la industria como ASME B46.1-2023. Este método destaca al fabricar piezas complejas con características como cavidades, ranuras y esas formas 3D complicadas que vemos en cosas como transmisiones de automóviles y componentes estructurales de aviones. Lo que lo hace confiable es el sistema de bucle cerrado que mantiene un seguimiento constante de la posición durante todo el proceso. Como resultado, los fabricantes pueden esperar superficies bastante suaves que oscilan entre aproximadamente 8 y 32 micro pulgadas de rugosidad promedio, lo cual es muy importante para el desempeño de estas piezas en sus aplicaciones finales.

CNC turning and Swiss machining for complex cylindrical parts

El torneado CNC produce componentes simétricos por rotación, como cuerpos de válvulas hidráulicas y accesorios para semiconductores, manteniendo tolerancias diametrales dentro de 0.0005". El mecanizado suizo mejora esta capacidad para piezas delgadas y de alta precisión, tales como tornillos para implantes dentales. Guiando el material a través de una bancada deslizante, permite realizar operaciones simultáneas de torneado y roscado manteniendo una concentricidad inferior a 0.0002" TIR.

Rectificado de precisión para acabados superficiales ultrafinos

El rectificado superficial proporciona acabados inferiores a 0.4 µm Ra utilizando abrasivos como óxido de aluminio o muelas CBN, esenciales para sellos de bombas y pistas de rodamientos. El rectificado de avance profundo combina altas tasas de eliminación de material (hasta 50 mm³/s) con precisión submicrónica, lo que lo hace adecuado para raíces de álabes de turbinas en turbinas de gas.

Mecanizado por descarga eléctrica (EDM) para geometrías complejas

EDM elimina material mediante descargas eléctricas controladas, permitiendo esquinas internas afiladas (hasta radios de 0.001") y perforación de micro-agujeros (Ø0.004") en materiales conductores. El corte por hilo EDM puede atravesar acero para herramientas de 12" de espesor con anchos de ranura menores a 0.006", preservando la integridad de aleaciones endurecidas utilizadas en boquillas de inyectores de combustible y moldes para fundición a presión.

Mecanizado CNC multiejes: Ampliando las capacidades más allá de los 3 ejes

los sistemas CNC de 5 ejes permiten inclinar y girar la pieza durante el fresado, posibilitando la producción en una sola configuración de piezas complejas como los diafragmas de aeronaves y prótesis ortopédicas. Un estudio del NIST de 2022 reveló que las configuraciones de 9 ejes reducen los tiempos de ciclo en un 62% en componentes prismáticos, manteniendo una precisión posicional dentro de 0.0008", acelerando la producción en la fabricación automotriz de vehículos eléctricos.

Preguntas frecuentes

¿Qué es el Fresado de Precisión?

La mecanización de precisión implica el uso de máquinas CNC controladas por computadora para fabricar piezas con tolerancias extremadamente ajustadas, a menudo hasta ±0,005 pulgadas, adecuadas para sectores como aeroespacial y dispositivos médicos.

¿En qué se diferencia la mecanización de precisión de la mecanización tradicional?

A diferencia de la mecanización tradicional, que depende del trabajo manual, la mecanización de precisión emplea sistemas CNC para procesos automatizados, logrando tolerancias tan ajustadas como ±0,001 pulgadas de manera consistente.

¿Qué papel juega la tecnología CNC en la mecanización de precisión?

La tecnología CNC es fundamental en la mecanización de precisión, convirtiendo diseños digitales en trayectorias de corte precisas y logrando alta precisión, repetibilidad y eficiencia en diversos sectores industriales.

¿Cuáles son las principales aplicaciones del fresado CNC?

El fresado CNC se utiliza para fabricar piezas complejas con alta precisión dimensional, adecuado para componentes como transmisiones de automóviles y soportes de aviones.

¿Qué beneficios ofrece la mecanización suiza?

La mecanización suiza es ideal para piezas esbeltas y de alta precisión, como tornillos para implantes dentales, permitiendo realizar torneado y roscado simultáneos mientras se mantiene una alta concentricidad.

Tabla de Contenido

- What is Mecanizado de precisión ? Definición y principios clave

-

El papel de la tecnología CNC en la consecución de precisión

- Introducción al mecanizado y fresado CNC en la fabricación de precisión

- Cómo los sistemas CNC mejoran la precisión, repetibilidad y eficiencia

- Evolución de la tecnología CNC y su impacto en la producción industrial

- Paradoja Industrial: Alto Costo Inicial frente a Precisión y Retorno de Inversión a Largo Plazo

-

La Mecanizado de precisión Flujo de trabajo: desde el diseño CAD hasta la inspección final

- Fase de diseño utilizando software CAD en flujos de trabajo de fabricación

- Programación CAM y Generación de Trayectorias de Herramienta para Ejecución CNC

- Configuración de Máquina, Selección de Material y Sujeción de la Pieza

- Ejecución del Mecanizado y Monitoreo en Tiempo Real

- Postprocesamiento, Inspección y Garantía de Calidad

-

Núcleo Mecanizado de precisión Técnicas y Sus Aplicaciones

- CNC fresado: Principios, aplicaciones y precisión dimensional

- CNC turning and Swiss machining for complex cylindrical parts

- Rectificado de precisión para acabados superficiales ultrafinos

- Mecanizado por descarga eléctrica (EDM) para geometrías complejas

- Mecanizado CNC multiejes: Ampliando las capacidades más allá de los 3 ejes

- Preguntas frecuentes