航空宇宙・防衛:高精度 CNC加工 高性能コンポーネント用

航空機製造における厳しい精度要求への対応

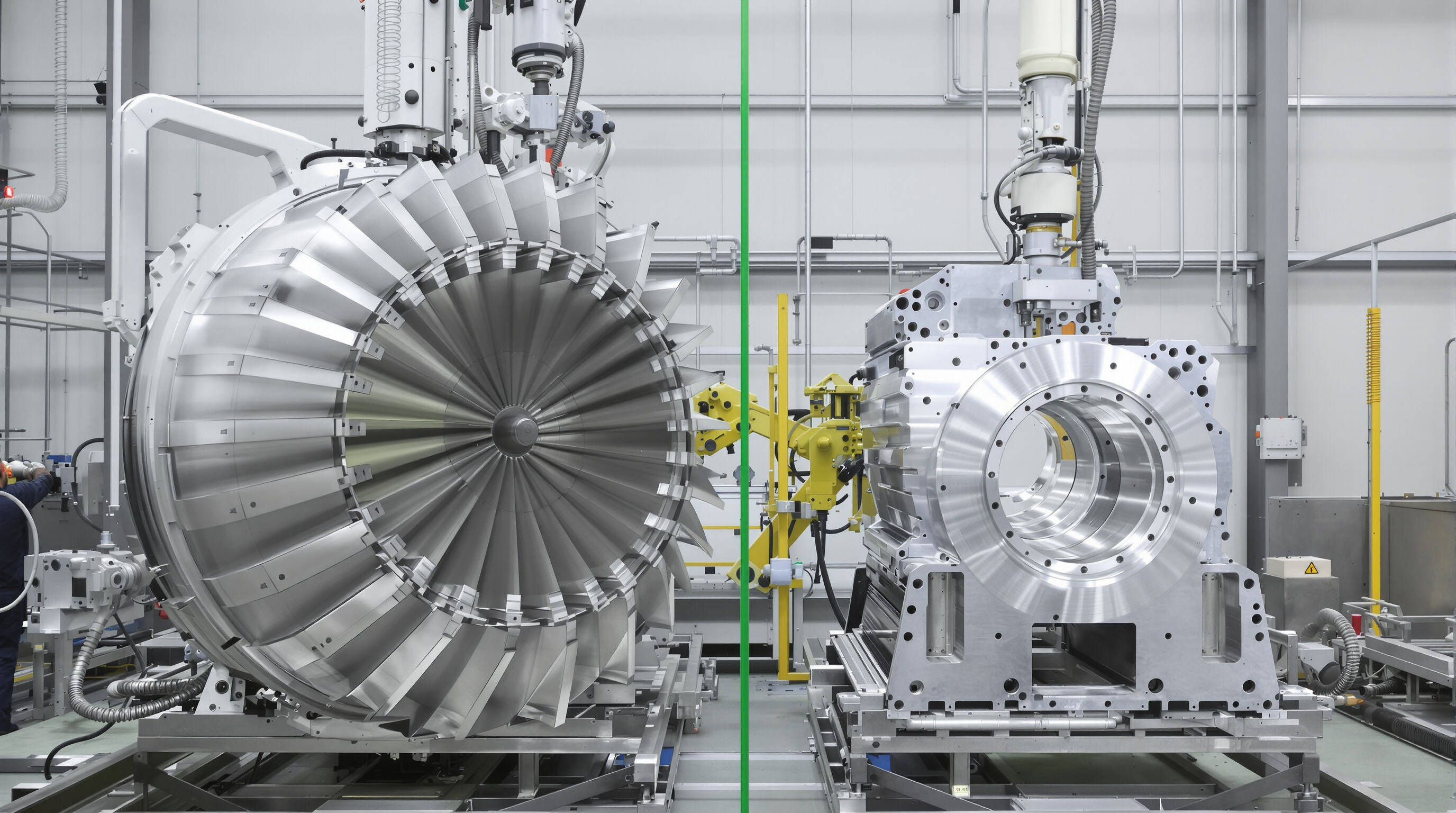

航空宇宙産業では、今日、数マイクロメートル単位の非常に高い精度で製造された部品が必要とされています。AMT Machineが2025年に発表した最新レポートによると、部品の仕様には、寸法公差がプラスマイナス0.0001インチよりも厳しい精度が求められることがよくあります。このような精度の実現には、コンピュータ数値制御(CNC)工作機械が5軸加工技術と高度なツールパスソフトウェアを用いることで対応しています。このようなシステムは、たとえばタービンブレードの製造のように、わずかな誤差が後に重大な問題を引き起こす可能性のある場面において特に重要です。また、Inconel 718で作られたエンジンマウントのケースを別の例として挙げることができます。2023年にZintilonが発表した調査結果によると、この素材は耐熱性に非常に優れていますが、飛行中の過酷な力にさらされてもその形状を保つためには、慎重な取り扱いが必要であるため、製造時には特別な切削加工手順に従う必要があります。

ジェットエンジンおよび無人航空機(UAV)部品製造におけるCNC

CNC技術は、商用および防衛用航空機の重要部品製造において主流となっています:

| 構成部品 | 材質 | 主要切削加工プロセス |

|---|---|---|

| タービンブレード | チタン合金 | 5軸高速ミリング |

| UAV構造ブラケット | アルミニウム7075 | 高精度スイス自動盤加工 |

| 燃料ノズル | ハステロイX | マイクロドリル&ECMハイブリッド |

これらのプロセスは、従来の方法と比較してリードタイムを40%短縮しながら、AS9100航空宇宙規格(PhillipsCorp 2024)への適合性を確保しています。

軍事用途におけるステルス性と耐久性の向上

軍事用CNCアプリケーションは、レーダー吸収材や装甲プレートに焦点を当てています。軽量アルミニウムリチウム合金は、弾道抵抗性を高めつつ航空機の機動性を損なうことなく応力除去処理を行うCNC加工を受けています。CNC制御によるステルスコーティング技術の最近の進展により、レーダー反射断面積を最大90%まで低減することが可能となっています(Baker Industries 2024)。

商用・防衛プロジェクトにおけるCNCスケーリングの課題

毎月10,000個以上の胴体用ファスナーを製造しながら、衛星用スラスターのような少量生産の専用部品も同時に生産するという大規模な生産ラインを管理しようとすることは、標準的なCNC加工の限界を押し進めています。多くの航空宇宙企業はここ最近、スマートマシニングシステムを導入し始めました。このような高度な設備は、工具摩耗をリアルタイムで監視しながら自動的に送り速度や切削速度を調整します。2024年春のHytech誌によると、この取り組みにより廃材を約22%削減する効果が得られています。しかしながら、通常のアルミニウム部品と比較して高価な防衛グレードのチタン部品の価格設定は、業界全体のメーカーにとって依然として大きな課題です。

Automotive and Renewable Energy: Driving Innovation with CNC Technology

High-Volume Production and Custom Prototyping in Automotive

自動車製造において、CNC工作機械は大量生産とカスタム部品の同時製造においてゲームチェンジャーとなっています。今日の高度なシステムでは、1日で約5,000個のエンジンブロックを生産することが可能です。これらのシステムが本当に印象的なのは、プラスマイナス0.005mmという非常に狭い公差を維持できる精度にあるのです。このような高精度は、EVのバッテリーケースやトランスミッション部品など、些細な誤差が問題を引き起こす可能性のある用途において特に重要です。また、標準的な生産と特別注文の両方に対応できるため、企業が軽量設計の試作を行うことも可能になっています。自動車メーカーが常にテストしているアルミニウム製サスペンションアームなどがその例です。このような生産は、現代の車両が複雑であるにもかかわらず、通常の生産スケジュールを遅らせることがないというのは、非常に注目すべき点です。

スマート製造:自動車組立工程へのCNCの統合

自動車メーカーは現在、IoT対応システムとCNCマシニングセンタを統合し、高速切削加工中にリアルタイムでの品質管理を実施しています。センサーにより工具摩耗や振動パターンを監視することで、ブレーキキャリパーおよびステアリング部品の不良率を18%削減しました(Automotive Tech Report 2023)。この接続性により、故障発生前にメンテナンスの必要性を予測することで、予期せぬ停止時間を最小限に抑えることができます。

グリーンエネルギー向けの風力タービンおよび太陽光部品の切削加工

CNC技術は再生可能エネルギー分野における大規模で腐食に強い部品の需要に対応します。5軸マシニングマシンは複雑な内部冷却チャネルを備えた風力タービンハブを製造し、40メートルのブレード設計においてエネルギー出力を12%向上させます。マリングレードのアルミニウムから切削加工された太陽光パネルフレームにはシームレスなインターロッキングジョイントが備わっており、洋上設置に最適です。

ケーススタディ:洋上風力発電用のCNC切削加工ギアボックス

欧州のエネルギーファームは、硬化処理済み4340鋼を使用したCNC加工のヘリカルギアに切り替えた結果、ギアボックスの故障率を34%削減しました。この高精度加工により、4.5メートルの直径を持つ部品においても均一な歯形を実現し、過酷な塩水環境下での15MWタービンの信頼性ある運転を可能にしました。この改善により、タービン1基あたり年間メンテナンス費用を22万ドル削減することに成功しました。

医療・海洋業界:CNCによるカスタマイズ性と信頼性

CNCの高精度による医療用インプラントおよびカスタム義肢の製造

CNC加工では、±0.001インチという非常に狭い公差でカスタムメイドの医療用部品を製造することができます。これは、人工関節や義肢などの製品を製造する際に特に重要な点です。このプロセスでは、チタンや特別な医療グレードのPEEKプラスチックといった生体適合性材料を用い、表面粗さをRa 0.8マイクロメートル以下まで仕上げることができため、体内で実際に良好に機能します。ジョンズ・ホプキンス大学の2023年の研究によると、CNC加工で製造されたチタン製人工股関節の約86%は、手術後10年間で補修を必要とせず、一般的な製造方法で作られたものより優れた結果となっています。

医療機器製造における規格・法令遵守の確保

CNCシステムは、FDAおよびISO 13485規格への準拠をデジタルでトレーサブルなプロセスを通じて効率化します。自動品質検査により、インプラント製造中に20以上の重要箇所で寸法精度をモニタリングし、誤差率はFDA監査済み施設で0.003%以下です。ASTM F136外科用インプラントプロトコルに準拠して検証されたCAD/CAMワークフローを統合することで、製造業者は99.7%のバッチ一貫性を実現します。

耐食性海洋部品およびプロペラ切削加工

コンピュータ数値制御(CNC)加工により、マリングレードアルミニウムおよび二相系ステンレス鋼から、±0.05ミリメートルの非常に高い精度で水力学的に優れた形状のプロペラが製造されます。この精度により、伝統的な手作りの製法と比較してキャビテーション問題を約27%削減できます。海水に強いブッシングやシャフト継手などの部品も優れた耐久性を示します。2024年にロイドレジスターが行った試験によると、これらの部品は約1万時間の運転後でも腐食によるクリープが0.01ミリ未満に抑えられています。また、5軸CNC技術により、可変ピッチプロペラブレードの製造も可能になります。このブレードにより、一滴一滴が貴重な洋上サービス船に搭乗する人々にとって、燃料消費を約18%削減する効果があります。

ケーススタディ CNC加工された チタン製人工膝関節

整形外科デバイスを製造する欧州企業が、各患者のために特別に調整された多孔質構造を持つチタン製膝関節を切削加工して使用し始めたところ、手術後の問題が大幅に減少しました。実際のチタン製部品は最初に3Dプリンターで製造され、その後、±5マイクロメートル以内の精度で切削加工されました。昨年NIHによる約1,200人を対象とした研究で検証したところ、医師らはこれらのインプラントと骨が約92%の割合で結合したことを確認しました。また、これらを用いた外科医らは別の点にも気づきました。それは、これらの部品が通常の手術用ナビゲーション機器と非常に良好に適合するため、手術時間平均で約34%短縮されたということです。手術中にすべてを適切に整えるための微調整が必要なくなったのです。

エレクトロニクス、鉱業、重工業:CNC加工能力の拡大

マイクロマシニングによる小型電子機器およびヒートシンクの製造

CNC加工は、マイクロコネクターやヒートシンクなど、現代の電子機器に使われる小さなが重要な部品の製造において、極めて重要な役割を果たしています。最新の5軸マシンは、『Precision Engineering Reports』の最近のデータによると、3マイクロメートル以下の公差に達することが可能であり、スマートフォン用アンテナやサーバー用冷却プレートなどの製造には不可欠です。IoTデバイスが年間約18%の成長率で拡大している現在、製造業者にとって、コンポーネントの小型化に対応しつつ、熱管理性能を維持するという課題に対応する能力が求められています。小型化と効果的な熱管理のバランスは、業界全体で引き続き重要な課題です。

鉱山機械用の耐久性のある金型および交換部品

最新のCNC加工により、超硬合金や高周波鋼などの素材を使用して、非常に耐久性の高いドリルビットやコンベア部品が製造されます。BGRグループの2023年の研究によると、この方法で製造された部品は、伝統的な鍛造製品と比較して2倍から4倍の長寿命化が可能となっています。このように寿命が延びることで、鉱物採掘作業中に装置が突然故障して作業が中断される頻度が減少します。自動化された工具経路最適化システムの導入により、状況は一変しました。特に遠隔地にある鉱山では、クッシャージョー部品や複雑な油圧バルブボディー部品の迅速な代替が必要です。通常のサプライチェーンから遮断された鉱山においては、こうした重要な部品を迅速に現場で製造できるかどうかが、作業の円滑な継続と高コストな停止との分かれ道となります。

メンテナンスおよび産業機械のアップグレードにおけるCNC

重工業の現場において、コンピュータ数値制御(CNC)技術は、古い機械を高精度の機械加工ギアボックスでアップグレードし、時代遅れのシステムに自動化された部品を追加する上で画期的な存在となっています。昨年に行われた工場の近代化に関するいくつかの最新の研究によると、手作りのシャフトをCNC工作機械で製造されたものに置き換えた結果、全体的に約40%の効率向上が見られました。これらのアップグレードは工場の完全な停止を伴わずに行うことができるので、特にシャフトの位置をミリメートル単位の数分の1まで正確に合わせることが、スムーズな機器の運転と高価な故障との違いを生む鋼鉄製造工場や発電所などの現場において、真の利点があります。

正しい選択 CNC機械 業界別アプリケーション向け

フライス加工、旋削加工、研削加工の比較 Cnc機械

CNCフライス盤は、タービンブレードや自動車用金型など、複雑な形状の製品を製造するのに非常に適しています。この加工方法では、固定された素材から不要な部分を削り取って製品の形状を作ります。ただし、円筒形の製品に関しては、旋盤のほうが適しています。エンジンシャフトや油圧継手などの部品は、旋盤で加工することができ、加工物を回転させながら固定された工具で削っていきます。また、研削機は表面を非常に滑らかに仕上げるのに用いられ、ミクロンレベルの精度まで達することができます。このため、医療インプラントの研磨や航空機で使用される小さなベアリングの加工にも最適です。

| 機械の種類 | 主な機能 | 一般的な材料 | 主要産業 |

|---|---|---|---|

| 磨き | 3Dコンタリング、ポケット加工 | アルミニウム、鋼、複合素材 | 自動車、航空宇宙、ロボティクス |

| 回転 | 円筒形状加工 | チタン、真鍮、プラスチック | エネルギー、防衛、海洋 |

| 磨き | 表面仕上げ、高精度加工 | セラミック、高周波鋼材 | 医療、光学、金型 |

生産ニーズと素材に基づく選定基準

CNC工作機械の選定においては、素材の適合性が実に約78%の選択に影響を与えると、2023年の業界調査で明らかになっています。自動車業界では大量生産が必要な際、自動工具交換装置付きの多軸マシニングセンタを採用する傾向があります。小ロットの生産を行う医療機器メーカーは、顕微鏡レベルの精度を達成できる研削機を必要とするケースが多いです。マリン分野においても特別な課題があります。ステンレス鋼やチタン素材を用いた部品を、塩水環境下で加工する際、多くの工場では過酷な環境に対応するため高度な冷却液フィルタリング機能を備えたCNC旋盤を採用しています。

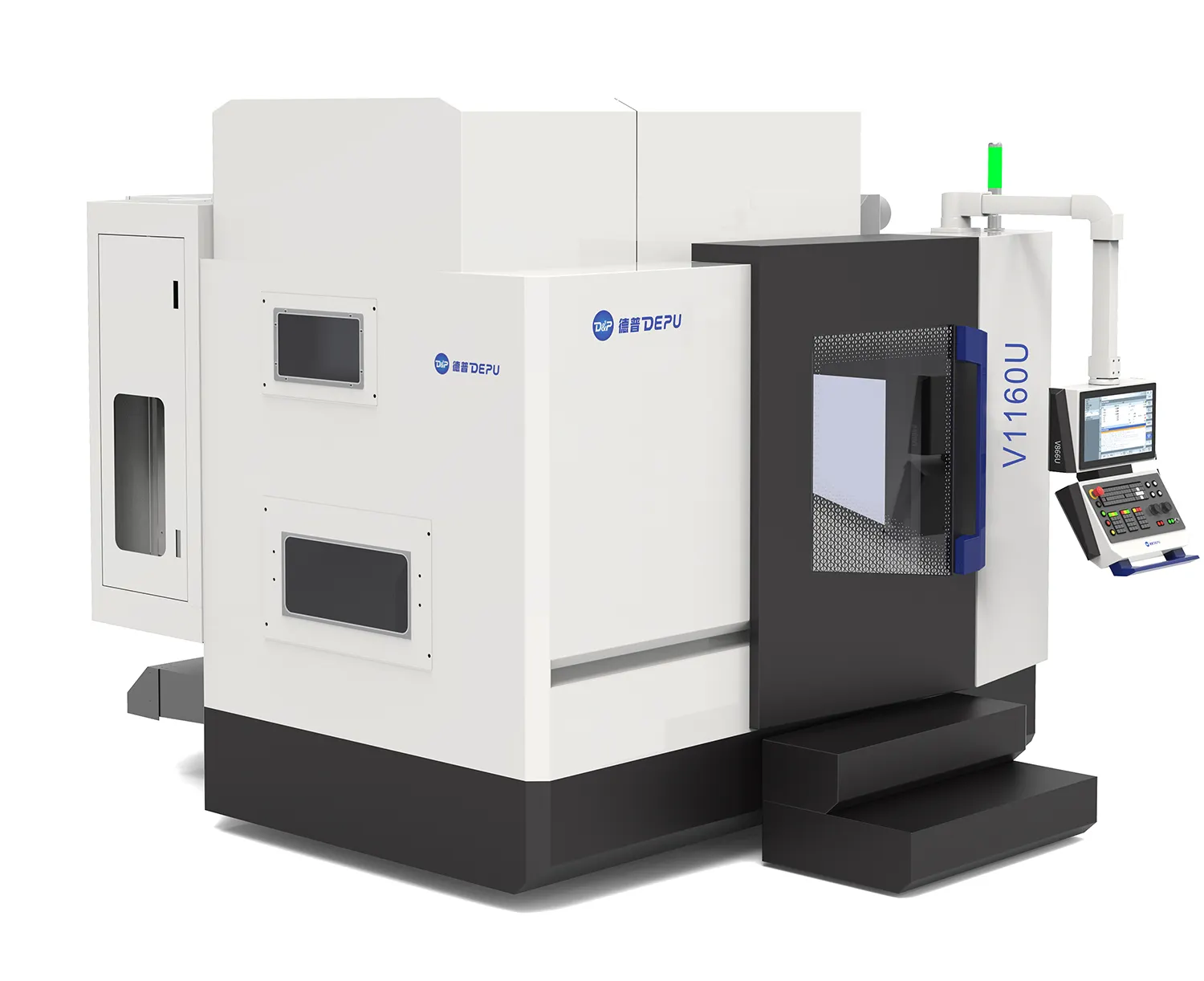

イノベーションスポットライト:DEPU CNC Shenzhen Co Ltd の産業ソリューション

深センDEPU CNC有限公司のハイブリッド5軸CNCマシンは、AI駆動の予知保全を統合しており、高_VOLUME自動車用途においてダウンタイムを31%削減します(2024年Industry 4.0レポート)。そのモジュラー式研削システムにより、チタン製膝関節やコバルトクロム歯科インプラントの生産に迅速に再構成可能で、医療機器製造におけるISO 13485の適合性を満たしています。

よくある質問セクション

CNCマシニングによって恩恵を受ける主な業界はどれですか?

航空宇宙、自動車、医療、海洋、電子、鉱業および重工業などの業界において、CNCマシニングは製造プロセスの精度と効率を提供する上で重要です。

製造におけるCNCマシニングの精度向上の仕組みは?

CNCマシニングは、コンピュータ制御システムを使用して狭い公差を維持し、複雑なコンポーネントの製造において高い精度を達成することで、一貫性と品質を保証します。

CNCマシニングで一般的に使用される材料はどのようなものですか?

一般的な材料にはアルミニウム、チタン、鋼、真鍮、複合材料、セラミックス、マリングレード合金、およびPEEKなどの特殊プラスチックが含まれます。

CNC加工のスケールアップにおいて企業が直面する課題は何ですか?

課題には大量生産の管理、材料の品質とコスト効率のバランス調整、廃棄物を削減し自動化を向上させるための高度な技術の統合が含まれます。