מה זה מכונת CNC 5 צירים ואיך זה שונה מהשיטות המסורתיות?

הכרת המושג מכונת CNC 5 צירים

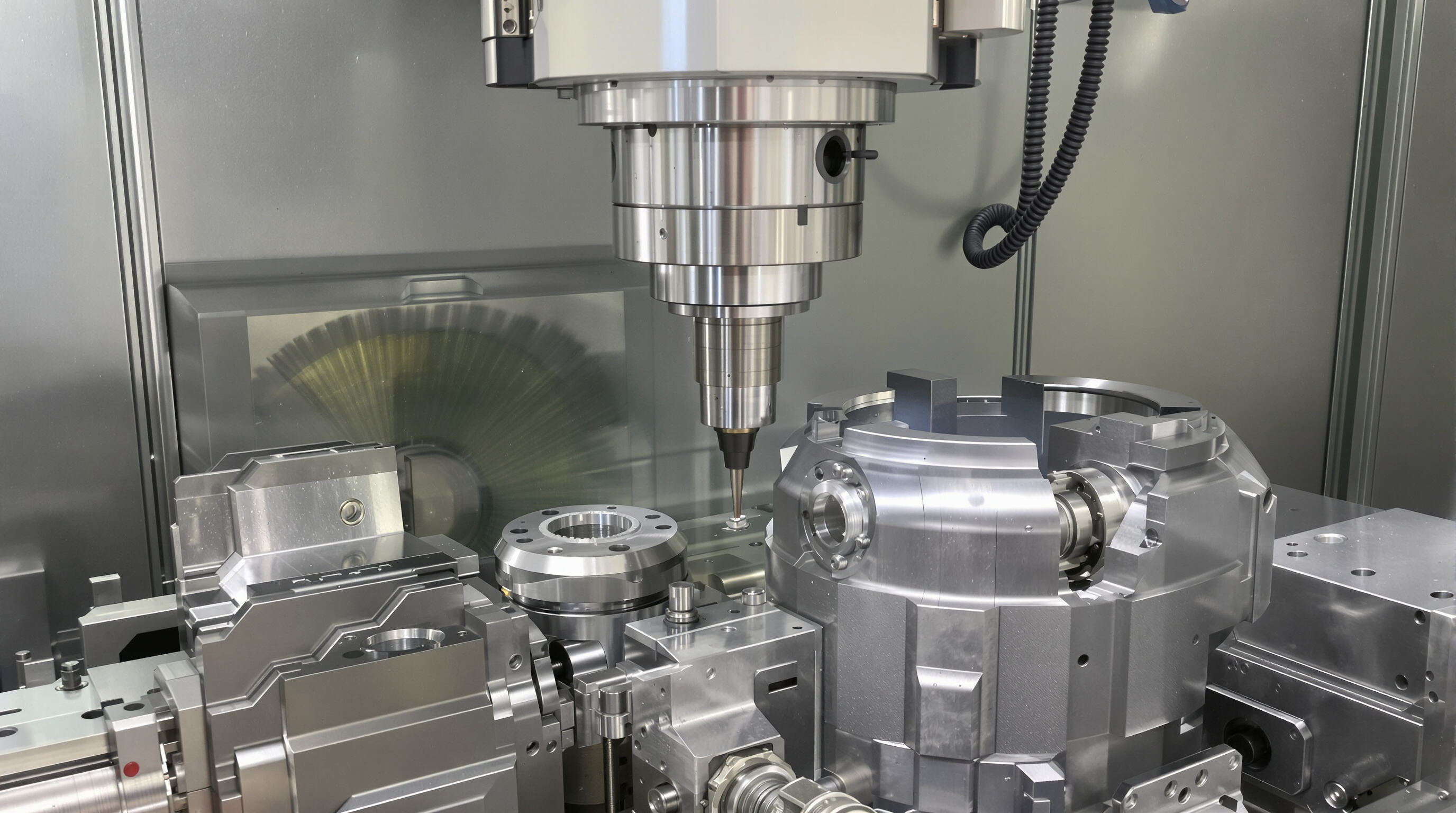

עיבוד CNC חמישה צירים פועל על ידי תנועה ב-5 צירים בו-זמנית - שלושה קווים ישרים (X, Y, Z) ועוד שני סיבובים (A ו-B). כלומר, כלי החיתוך יכולים להגיע לכל חלק של חתיכת העבודה מבלי שיהיה צורך לעצור ולסובב את הדברים באופן ידני. אין עוד צורך בהצבה מחדש tedious, מה שמחסוך זמן ומעלים את הדיוק. מכונות יכולות לשמור על ספּקִים צרים מאוד, עד כ-0.005 מילימטר, ולכן הן מצוינות לייצור חלקים מורכבים כמו להבים למנועי מטוסים או התקנים רפואיים זעירים שיכנסו לגוף. כשנכנסים לפעולה התנועות הסיבוביות, יצרנים מקבלים גישה מלאה לכל מיני צורות קשות וחלקים שאינם נגישים בקלות. עבור תחומים שבהם דיוק הוא קריטי, טכנולוגיה זו שינתה לחלוטין את מה שאפשרי ב Этаж הייצור.

ההבדלים המרכזיים בין מכונת CNC שלושה צירים לחמישה צירים

מכונות תלת-צירים סטנדרטיות פועלות בקווים ישרים לאורך הכיוונים X, Y ו-Z, מה שמקשה עליהן בעבודה עם צורות ותכולות מורכבות משני הצדדים, אלא אם הן עוצרות ומבוצעות אתחול מספר פעמים. בכל פעם שמכונות אלו נזקקות להזזה למיקום חדש, קיים סיכון לאי-יישור נכון, וצעד זה צורך anywhere בין 40 ל-70 אחוזים נוספים בזמן ייצור, לפי דוחות תעשייתיים של SME משנת 2023. מאידך, מערכות חמישה צירים מציגות את הצירים הסיבוביים הנוספים A ו-B, המאפשרים לעדכון או לחלקו עצמו לשנות זווית תוך כדי חיתוך החומר. התוצאה? חלקיים עם מרווחים פנימיים מורכבים ומשטחים בזווית מסתיימים ללא עצירה, ומצילות לייצרנים כ-50 אחוז מהזמן לייצור רכיבי מטוס כאשר הגישה לכמה צדדים בו-זמנית היא חיונית.

ההתפתחות ביכולות וביתרונות של עיבוד רב-צירים

שורשי הטכנולוגיה בת 5 צירים חוזרים לשנות ה-80 כאשר היא שימשה לראשונה בעבודה בחלל-חלל ובגנת עבודה עבור עיבוד רכיבים מוצקים של טיטניום. מאז 2010 דברים השתנו מעט, הודות לפיקוח CNC טוב יותר ולשיפורים בתוכנה CAM. מה שזה אומר למעשה הוא שמכונות יכולות כעת לנוע לאורך כל חמשת הצירים בבת אחת, מה שעושה הבדל אמיתי על רצפות המפעל. המספרים מספרים חלק מהסיפור גם כן - חנויות מדווחות על צורך בכחצי פחות תאים, מקבלים משטחים גלימים ב-35% באופן כללי, וכלים נמשכים בערך 30% יותר כי הם חותכים בזוויות טובות יותר על פי מחקר מכתב העת של מערכות ייצור בחזרה בשנת 2022. תעשיות שבהן דיוק חשוב יותר כמו מכשירים רפואיים, רכיבי מטוסים, וייצור ציוד אנרגיה אימצו את הטכנולוגיה הזאת בכל לב. שיעור הרסיסים בלבד ירד ביותר מרבע במקרים רבים לאחר המעבר למערכות 5 צירים.

חמשת הצירים מסודרים: X, Y, Z, A, ו B מכונות CNC 5 צירים

צירים לינאריים (X, Y, Z) ותפקידם במיקוד כלי החריטה

בעיבוד ב-CNC, הצירים X, Y ו-Z פועלים יחד כדי לשלוט בתנועת כלי החריטה במרחב תלת-ממדי. נפריד לשלבים: הציר X אחראי לתנועה מהצד השמאלי לצד הימני של שולחן המכונה, מה שמאפשר פעולות כמו חריטת פנים. הציר Y אחראי למיקוד מהצד הקדמי לצד האחורי, והוא חשוב במיוחד בחריקה צדדית או ביצירת חריצים. הציר Z אחראי לתנועה מעלה ומטה, הדרושה לחריצה ולחורצות. כאשר כל שלושת הצירים פועלים כראוי, הם יכולים למוקד כלי עבודה בדיוק של פלוס או מינוס 0.005 מילימטר, בהתאם לתקן ה-ISO מ-2022. רמת הדיוק הזו היא מה שמאפשרת לייצרנים לייצר חלקים באופן עקבי, שוב ושוב.

צירים סיבוביים (A ו-B) והשפעתם על אוריינטציה של החלק המעובד

בעת דיבור על צירי מכונה, ציר ה-A מסתובב את חתיכת העבודה או את הציר הראשי בכיוון שנקרא ציר ה-X. בינתיים, ציר ה-B אחראי לסיבוב סביב ציר ה-Y. מה שזה אומר בפועל הוא שהכלים יכולים להגיע לזויות המורכבות הללו מבלי שיהיה צורך בהתקנה חוזרת ונשנית. ניתן לחשוב למשל על ייצור מנועי סילון, שם נטייה של 45 מעלות בציר ה-B מאפשרת למכונאי לנקב חורים בזוית בתושבות המגננה בדיוק מופלא. הvantג האמיתי כאן הוא הסילוק של כל התאמות ידניות שדורשות זמן. יצרנים יכולים כעת לעבד שקעים מורכבים וצורות מעוקלים שקודם לכן דרשו התקנות רבות וציוד מיוחד.

קינמטיקה של תנועה מסונכרנת מחמישה צירים (צירים X, Y, Z, A, B/C)

עיבוד ממשי ב-5 צירים מתבצע על ידי שילוב כל חמישה הצירים במקביל - גם תנועות ליניאריות וגם סיבובים, דבר האפשרי בזכות תוכנת בקרת תנועה מתקדמת. כאשר כל הרכיבים מסודרים כראוי, כלי החיתוך שומרים על אותו זווית ביחס לחתיכה לאורך כל התהליך. משמעות הדבר היא הסרת חומר בצורה אחידה במעבר על צורות מורכבות, מבלי להותיר את החריגים הבלתי נראים לעין. ליישומים מעשיים, חלקים שמיוצרים מחומרים קשיחים כמו טיטניום, המשמשים בבניית מטוסים, יכולים להשיג גימור משטח מתחת לרמה של 0.8 מיקרון. תוצאות כאלו הן בדיוק מה שסטנדרטים תעשייתיים דורשים עבור רכיבים בעלי ביצועים גבוהים, בהם דיוק הוא בעל חשיבות מכריעה.

איך שליטה במסלול ובכיוון הכלי תורמת להגביר דיוק ב מערכות 5-axies

אופטימיזציה של כיוון הכלי היא יתרון מהותי של מערכות חמשת הצירים. על ידי התאמת זווית הכלי ביחס לחתיכה:

- כוחות החיתוך מתאימים את עצמם לציר החזק ביותר של הכלי, ובכך מקטינים את הסטייה עד ל-40%

- קוטר החיתוך האפקטיבי נשאר קבוע על פני משטחים מעוקרים

- כלי קצרים וקשיחים יותר ניתן להשתמש בזוויות אופטימליות

גורמים אלו יחדיו מאפשרים עיבוד ב précisião גבוהה של תכונות עדינות, כגון פינות רדיוס של 0.2 מ"מ באימפלנטים רפואיים, עם חזרתיות תת-מיקרונית

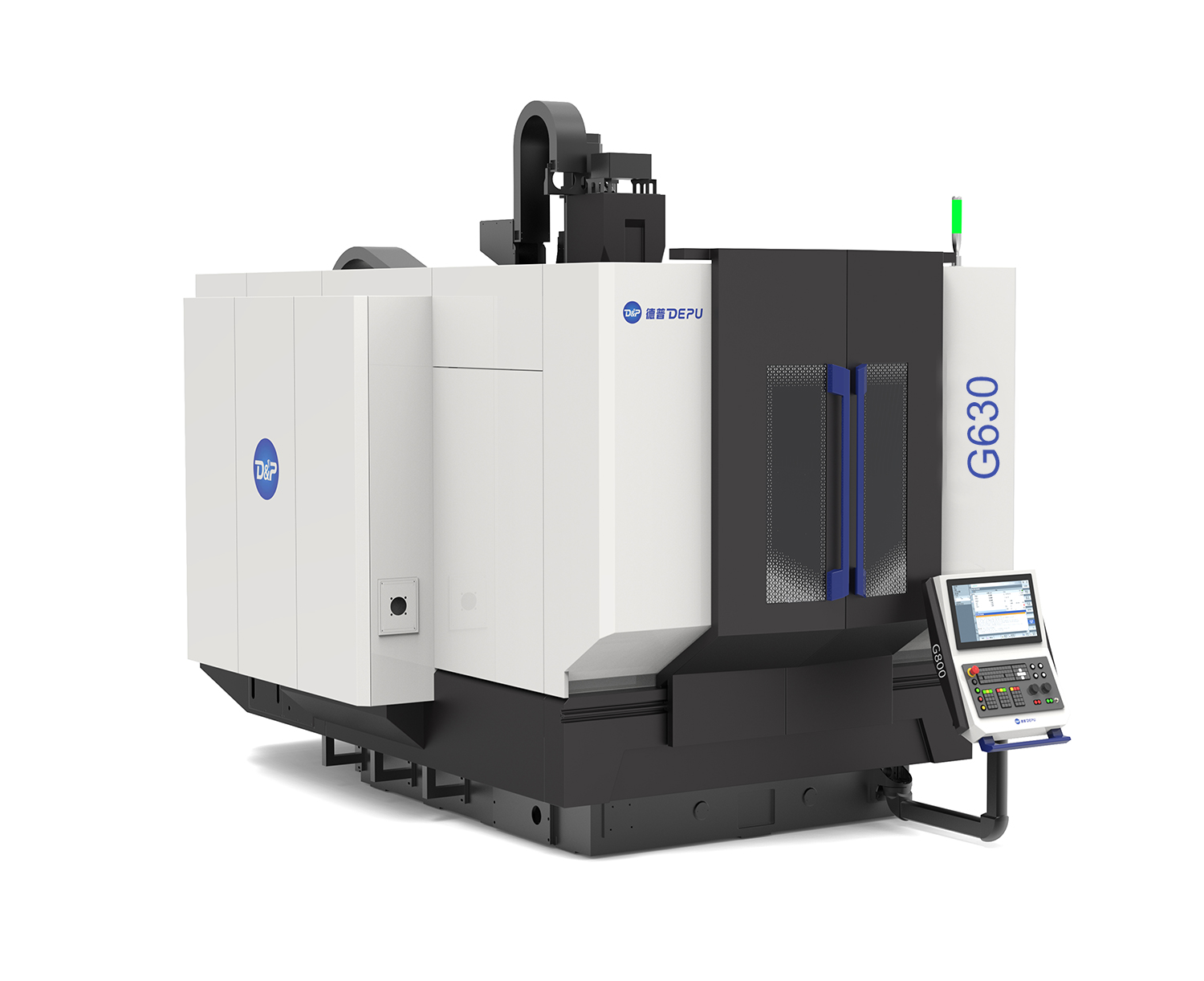

סוגים ותצורות של מכונות CNC 5 צירים : ראש/ראש, שולחן/ראש, ושולחן/שולחן

בנוגע למרכזי עיבוד חמישה צירים, כיום יש שתי שיטות עיקריות לבנייתם. האפשרות הראשונה נקראת מכונה בסגנון טרוניון שבה השולחן עובד מסתובב. מכונות אלו פועלות בצורה מצוינת עבור חלקים בעלי צורה של תיבה מכיוון שהיא מספקת גישה טובה ממספר זוויות, אם כי יש להן הגבלות מסוימות מבחינת המשקל שהיא יכולה להכיל. הסדרה הנפוצה השנייה ידועה בשם סגנון סיבוב נטוי. בעזרת רכיב זה, הציר עצמו מכיל את הצירים המסתובבים אשר מאפשרים לכלי להגיע לתוך כל מיני צורות מורכבות שלא היו אפשריות אחרת. מה שעושה את שני הסוגים לחשובים זה היכולת שלהם לשלב מספר צירים בו-זמנית במהלך הפעולה. כלומר, פחות פעמים שבהן צריך לעצור ולמקם מחדש את החלקים, מה שэкономת זמן וכסף במיוחד כשמטפלים ברכיבים מורכבים שיש להם תכונות רבות.

סקירה כללית של קונפיגורציות מכונות CNC בחמישה צירים (סגנון טרוניון, סגנון סיבוב נטוי)

מכונות סגנון טרוניון פועלות על ידי סיבוב החלק בעבודה על שולחן נוטה מסביב למה שאנו מכנים ציר ה-X. הקונפיגורציות הללו טובות למדי בעבודה עם חלקים בצורת תיבה שכן הן יכולות לגשת למספר צדדים בקלות. אך יש חיסרון גדול אחד - כשמדובר בחלקים גדולים או כבדים יותר, המכונות הללו פשוט אינן בנויות כדי להתמודד עם עומסים כאלה בצורה יעילה. לעומת זאת, קואן סיבוב מסתובבות גישת שונה לגמרי. במקום תזוזת השולחן כולו, הצירים הרוטריים מותקנים ישירות לתוך ראש הספינדל עצמו. זה מאפשר לכלי למקם את עצמם בזוויות שונות, החל מפלוס או מינוס 30 מעלות ועד 120 מעלות. היתרון האמיתי כאן בא לידי ביטוי כשמטפלים במשטחים חופשיים מורכבים שבהם דיוק הוא חשוב ביותר. יצרנים בתחום התעופה והרפואה מעריכים במיוחד את היכולת של מכונות אלו לשמור על ספירות דקיקות ביותר, עד סטיות של 0.0001 אינץ', מה שהופך אותן ללא dispensables ליישומים קריטיים שבהם גם סטייה זעירה יכולה להוות בעיה.

ראש/ראש לעומת שולחן/ראש לעומת שולחן/שולחן: פער ביצועים ויישומים

במקרים בהם הראש/הראש נמצאים במבנה קבוע, החלק נשאר במקום והצינורית אחראית על כל הסיבוב, מה שמאפשר יציבות טובה יותר בעבודה על חלקי תעופה גדולים. קיים גם שילוב בין שולחן/ראש, שבו משלבים שולחן סיבוב וצינורית נוטה. מבנה זה פועל די טוב לייצור תבניות וציוד רפואי, מאחר שהוא מציע שילוב טוב בין היכולת להתמודד עם צורות שונות לבין נפח העבודה. במכונות מהסוג שולחן/שולחן, כל התנועה מתמקדת בסיבוב החלק עצמו. מכונות אלו מסוגלות לייצר חרטות מורכבות מאוד, אך בשטח עבודה מצומצם. בבחירת המערכת המתאימה, יצרנים צריכים לשקול את רמת המורכבות של החלקים, נפח הייצור, והאם העיצובים דורשים גאומטריות מיוחדות שהמערכות הסטנדרטיות עשויות לא לספק.

| תצורה | יציבות דיוק | תכולת עבודה | מהירות | מקרים של שימוש אופטימלי |

|---|---|---|---|---|

| ראש/ראש | ⭐⭐⭐⭐⭐ | גדול | בינוני | להטורים של טורבינה, גוףPeshto |

| שולחן/ראש | ⭐⭐⭐⭐✩ | בינוני | גבוה | תומכים רפואיים, תבניות |

| שולחן/שולחן | ⭐⭐⭐⭐✩ | קטן | נמוך | תכשיטים, שיניים מלאכותיות |

לצורות אורגניות גבוהות כמו להטורים של טורבינה, עיבוד חמשת הצירים ברציפות מביא יתרונות כלכליים ואיכותיים. לחלקים מרובים פאות פשוטים, שיטות אינדוקטיביות (3+2) מספקות לרוב.

איך מכונת CNC 5 צירים ר orks: מ lậpن/CAM תכנון לביצוע

איך עובד מכונת CNC בע_AXIS 5: פירוק שלב אחר שלב

בתחילת התהליך, מהנדסים משתמשים במודל CAD כדי לבנות תכנית תלת-ממדית של הרכיב שAwaiting translation...

שיטה עם אינדוקס (3+2) לעומת שיטה רציפה במכונות בע_AXIS 5

| טכניקה | סוג תנועה | יישומים אידיאליים | השפעה על זמן מחזור |

|---|---|---|---|

| ממוספר (3+2) | צירים סיבוביים ננעולים לפני חיתוך שלושה צירים | חלקים פראיזמטיים מרובדי פאות | 15-20% מהיר יותר לייצור בשורות |

| רציף | תנועה סימולטנית של חמישה צירים במהלך החיתוך | קונטורים אורגניים (למשל, להבים לטורبينים, שתלים רפואיים) | הפחתה של עד 40% לעומת כמה התקנות |

עיבוד ממוספר הוא יעיל לחלקים עם תכונות זוויתיות בדידות, בעוד תנועה רציפה בחמישה צירים היא חיונית לקונטורים חלקים ומסובכים שדרשו אחרת גימור ידני.

תפקיד תוכנת CAD/CAM בתכנות מסלולים מורכבים של כלים

התוכנה CAM הפכה להיות חיונית לתכנות משימות 5 צירים, מטפלת בחישובים מורכבים סביב מיקום הכלים, זוויות הכניסה ומניעת התנגשויות במהלך תהליכי העיבוד. אלגוריתמי התוכנה מטפלים בתאמות הדרושות לשרשראות כלים שונות, מתקנות כל היסט בפריט העבודה ומביאות בחשבון את אופן התנועה של המכונות בפועל - משהו שחשוב במיוחד כשמדובר בתכונות מורכבות כמו כיסים עמוקים או אזורים עם שקעים. לאחר שהשלמת התכנון הזה, מתבצע תהליך סופי שבו המסלולים המחושבים ממירים לפקודות G-code מדויקות המתאימות לכל מכונת CNC ספציפית. יצרנים שעברו לזרימה דיגיטלית כזו דיווחו על ירידה של כ-70-75% בשגיאות תכנות בהשוואה לשיטות ידניות ישנות, על פי נתוני תחום עדכניים מתקופת סוף 2023.

מתי נדרש 5 צירים רציף לעומת זה שזו הגזמה? שיקולים מעשיים

עיבוד חמישה צירים באמת מבריק כשמטפלים בצורות מורכבות או זוויות קשות, חישבו על דברים כמו תומכים למנועי מטוסים או התקנים רפואיים המושתלים בחוט השדרה. אך כשמביטים בחלקים בסיסיים יותר, כמו סריטי התקנה או יחידות תיבה עם זוויות ימניות פשוטות, עדיף לבחור בטכניקות של 3+2 עם אינדוקס או פשוט עיבוד שלושה צירים רגיל שמבצע את המשימה היטב. שיטות חלופיות אלו מפחיתות את כאבי הראש בתכנות ומאיצות את התהליך ביחס של שליש לעומת עבודה רציפה בחמישה צירים. לממשיכי מפעלים שמנסים לבחור את האפשרות המתאימה, ההיגיון מחייב לבחון את מה שבעצם צריך להיבנות לפני קניית ציוד יקר. התשלום האמיתי מגיע מפריטים בעלי צורות ייחודיות שבהן שיטות התקנה מסורתיות היו אורכות נצח ומעלות המון כסף.

יתרונות ויישומים של 5 ציר CNC עיבוד בתעשייה

דיוק מוגזם, גימור משטח משופר ופחות התקנות עם מכונות חמישה צירים

כאשר הכלים נשארים מעורבים כראוי במהלך פעולות החיתוך, מכונות CNC בעלות 5 צירים יכולות לייצר סיימום משטח מתחת ל-16 מיקרו אינץ' Ra ולמנוע הצטברות שגיאות מעיקות הנובעות מהתאמת מכונה מספר פעמים. מה ש naprawdę מצחיק? זמני התפוקה יורדים ב-40 עד 60 אחוזים. זה הופך להבדל האמיתי בעבודה על חלקים חשובים כמו להבי טורבינה או שתלים רפואיים. בסופו של דבר, איכות המשטח אינה רק עניין של מראה – זה משפיע על ביצועי הרכיבים ביישומים שבהם הם מיועדים.

עיבוד גאומטריות מורכבות וקווי מתאר מסובכים באופן יעיל

תנועה סימולטנית של חמישה צירים מאפשרת ייצור של צורות מורכבות ביותר – כגון להבי טורבינה, שלדי עצמות ותבניות הזרקה – בפעולה בודדת. יכולת זו מקטינה את הצורך ברכיבים ואסמבליות רבות, מצמצמת את מספר הרכיבים ב-30% ומשפרת את האמינות המבניתיתית על ידי הסרת מפרקים.

אורך חיים של כלי עבודה משופר ויעילות קדיחה דרך זוויות כלים אופטימליות

כאשר כלים מסתובבים על צירם, הם פוגעים בחומרים בזווית הנכונה בדיוק לצורך יעילות מקסימלית. זה שומר על הקשר בין הכלי לחומר יציב לאורך הצדדים ולא מתיר לו לחפור למרכז שבו מתרחש בלאי מהיר. העובדה שהבְּלַיִת מתקדמת באופן שווה לאורך שפת הגילוף פירושה שכלים אלו נמשכים זמן רב יותר לפני שהצורך להחליפם עולה. הסרת שבבים טובה יותר היא עוד יתרון שכן היא מונעת הצטברות מוגזמת של חום במהלך הפעולה. מה שמייחד את הסידרה הזו? מקדחות שומרות על נקודות כניסה ישרות גם בעבודה מול פני שטח מעוקלים. התוצאה? חתכים וחללים נקיים המדדים נכון בכל פעם, מה שחשוב במיוחד בסביבות ייצור מדויקות.

עלות התחלתית גבוהה לעומת תשואה ארוכת טווח: הערכת ההשקעה בטכנולוגיית מכונת CNC בעבודה פולישית

בעוד מכונות 5 צירים בהחלט עולות יותר בהתחלה, רוב החנויות מוצאות שהם חוסכים כסף לאורך זמן. קחו את חברת התעופה הזו כדוגמה. הם קיצצו את זמן העיבוד של חלקים מאוד מורכבים מ-18 שעות שלמות זה בערך שיפור של 70 אחוזים. כאשר חנויות נפטרות מהשלבים הנוספים האלה והפסיקו להסתמך כל כך על עבודה ידנית, מהירות הייצור שלהם עולה. זה אומר שחנויות המכונות יכולות להתמודד עם עבודות מורכבות יותר, ההפכה המהירה יותר מסייעת להחזיר את ההשקעות הראשוניות האלה מהר יותר מהצפוי.

יישומים קריטיים בתעופה וفضاء, רפואה ואנרגיה

מהפיכת ה-5 צירים בעיבוד מכאנלי בולטת במיוחד במקטעים שבהם הרגולציה חמורה ואין אפשרות להתפשר על הביצועים. דוגמה לכך היא תעשיית התעופה, הסומכת על טכנולוגיה זו לייצור רכיבים כמו צלעות כנף וחיבורי מנוע שדורשים דיוק אקסטרמי בתכונות האירודינמיות שלהם. גם התחום הרפואי נהנה רבות מהשימוש במכונות אלו. כירורגים יכולים כעת לקבל סורגים עמוד השדרה מותאמים אישית ותומכים גולגולתיים המיוצרים בהתאם לאנטומיה הייחודית של כל חולה. גם חברות האנרגיה מפיקות תועלת מהן, מכונת CNC 5 צירים ויוצרות מהן רכיבים מורכבים כמו נווזלים לטורבינות וחלקי סיעור לפאומים. מה שעושה את כל זה כל כך מרשים הוא הэкономיה בזמן ובכסף שנוצרת דרך שיפורים בתהליכי עבודה. industry of cardiac monitors - בואו ניקח לדוגמה את תעשיית מוניטורי קרדיאק, שבה בדידים ניסיוניים היו מצריכים בעבר 15 שלבי הכנה שונים, והיום רק שלושה. צמצום שכזה מקצר את זמני הייצור ופוחת את הסיכוי לטעויות ביצור.

תוכן העניינים

- מה זה מכונת CNC 5 צירים ואיך זה שונה מהשיטות המסורתיות?

- חמשת הצירים מסודרים: X, Y, Z, A, ו B מכונות CNC 5 צירים

- צירים לינאריים (X, Y, Z) ותפקידם במיקוד כלי החריטה

- צירים סיבוביים (A ו-B) והשפעתם על אוריינטציה של החלק המעובד

- קינמטיקה של תנועה מסונכרנת מחמישה צירים (צירים X, Y, Z, A, B/C)

- איך שליטה במסלול ובכיוון הכלי תורמת להגביר דיוק ב מערכות 5-axies

- סוגים ותצורות של מכונות CNC 5 צירים : ראש/ראש, שולחן/ראש, ושולחן/שולחן

- איך מכונת CNC 5 צירים ר orks: מ lậpن/CAM תכנון לביצוע

-

יתרונות ויישומים של 5 ציר CNC עיבוד בתעשייה

- דיוק מוגזם, גימור משטח משופר ופחות התקנות עם מכונות חמישה צירים

- עיבוד גאומטריות מורכבות וקווי מתאר מסובכים באופן יעיל

- אורך חיים של כלי עבודה משופר ויעילות קדיחה דרך זוויות כלים אופטימליות

- עלות התחלתית גבוהה לעומת תשואה ארוכת טווח: הערכת ההשקעה בטכנולוגיית מכונת CNC בעבודה פולישית

- יישומים קריטיים בתעופה וفضاء, רפואה ואנרגיה