Understanding the Core Mechanics of 5 Axis CNC Machining

Definition and fundamental mechanics of 5-axis CNC machining

Five axis CNC machines combine standard X, Y, Z movements with additional rotation along A and B axes, which lets tools work across all five dimensions at once. What makes this technology so valuable is that it can handle complicated shapes from different directions without stopping and moving parts around manually. Manufacturers save time because they don't have to keep adjusting positions between cuts. Plus there's less room for mistakes building up over multiple operations. Some industry reports suggest error rates drop somewhere around 40 percent when switching from traditional three axis systems to these advanced five axis setups.

Simultaneous multi-axis movement and its impact on accuracy

True 5-axis machining synchronizes all axes during cutting, maintaining optimal tool-to-workpiece alignment. This capability achieves tolerances within ±0.005 mm—critical for aerospace components—while improving surface finish quality by 30% through consistent chip load distribution, as shown in Industry research.

Types of 5-axis CNC machine configurations: Trunnion vs. swivel-rotary

| Configuration | Best For | Accuracy Advantage |

|---|---|---|

| Trunnion | Heavy components | ±0.0025 mm repeatability |

| Swivel-rotary | Complex organic shapes | 0.01° angular precision |

Trunnion systems rotate the workpiece via an A-axis tilting table, making them ideal for large, heavy parts like turbine housings. Swivel-rotary designs combine a rotary table with a pivoting spindle head, excelling at producing intricate contours found in medical implants.

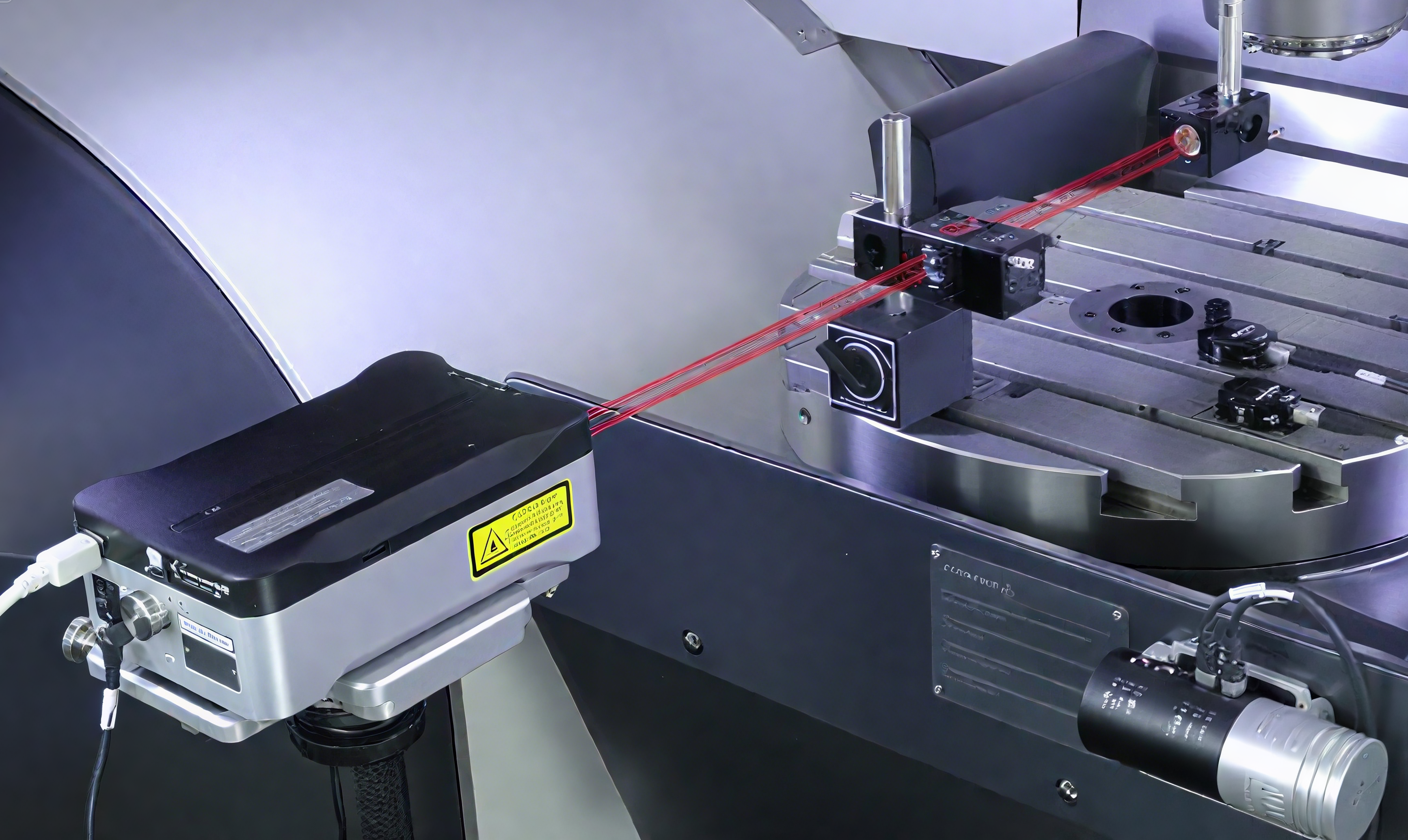

The role of advanced motion control in precision execution

The latest generation of 5-axis CNC machines now incorporates brushless servo motors along with encoders that offer impressive 0.1 micrometer resolution, plus they come with adaptive vibration damping features. What makes these systems stand out is their ability to adjust for tool deflection as it happens, which means the machine stays accurate even when running at those crazy high speeds like 15,000 RPM. Some research on 5-axis machining suggests that dynamic thermal compensation can cut down thermal drift errors by around 70 percent over long production runs. This kind of performance really matters for shops dealing with tight tolerances and complex parts.

Precision Advantages: How 5 Axis CNC Machining Minimizes Errors and Maximizes Accuracy

Achieving Tight Tolerances with ±0.01mm Accuracy in 5 Axis CNC Machining

Today's 5 axis systems can reach tolerances down to plus or minus 0.01 mm because they keep the cutting tool constantly touching complex shapes throughout the entire machining process. This kind of control simply isn't possible with older 3 axis machines. The aerospace industry really takes advantage of this technology for parts like turbine blades and those curved airplane wing sections called airfoils. These advanced systems make real time adjustments to the cutting path while working around tricky angles, which means manufacturers get consistent results at the micrometer level. We saw exactly this happening in practice during the Neway Precision case study where their production quality improved dramatically after switching to 5 axis machining.

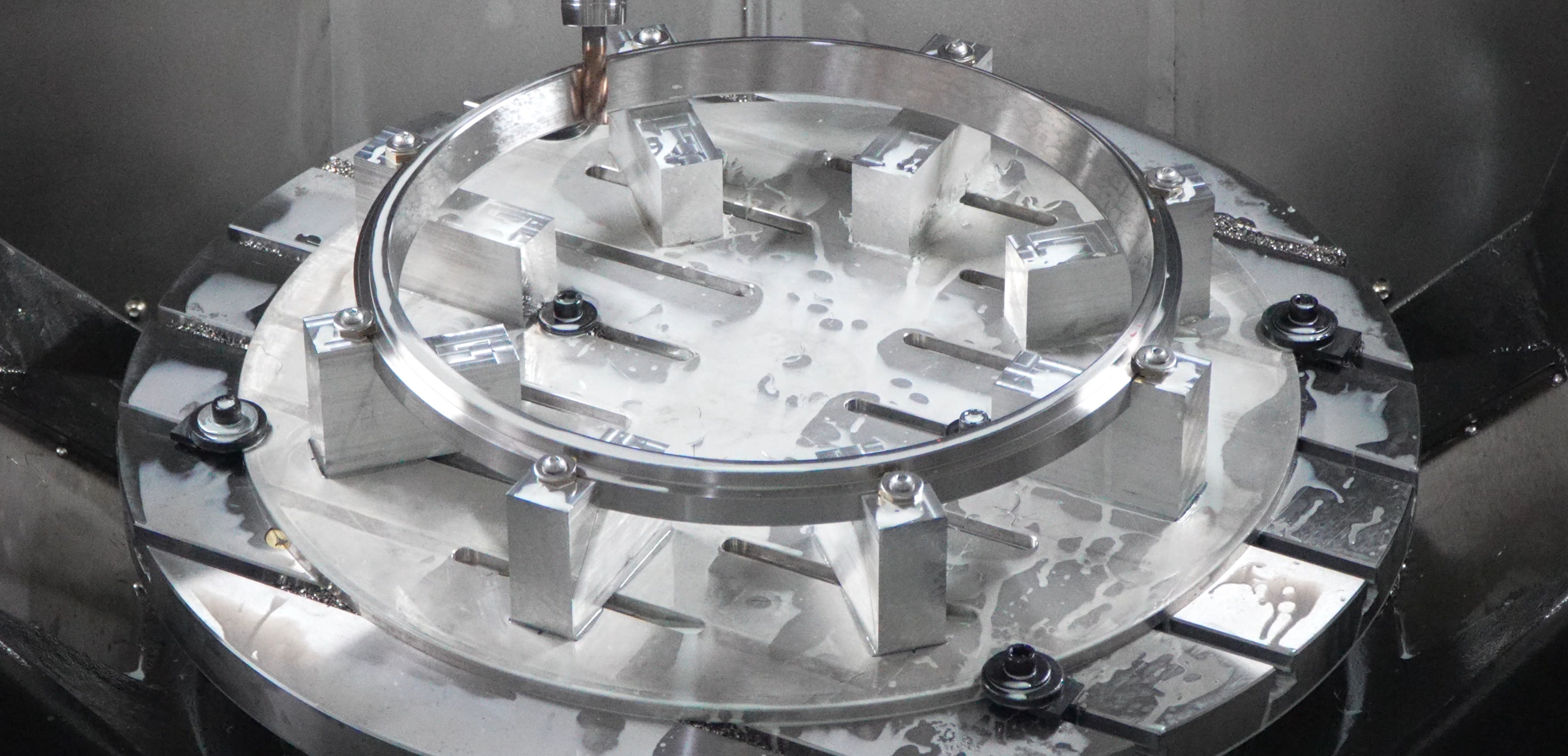

Reduction of Cumulative Errors Through Single Clamping Process

By completing multiple machining operations in one setup, 5-axis CNC eliminates the error stacking caused by repeated fixturing. This approach reduces dimensional deviations by up to 70%, removing misalignment risks associated with part repositioning.

Error Elimination Via One-Time Setup and Enhanced Repeatability

With only one clamping required, positional repeatability reaches within 5 microns across production runs. As noted in precision manufacturing analyses , this consistency significantly reduces manual intervention while doubling output reliability for high-precision sectors like medical devices and optics.

Superior Surface Finishes Enabled by Optimal Tool Orientation

The ability to tilt the tool ensures it maintains the ideal cutting angle, minimizing scallop marks and achieving surface finishes as fine as Ra 0.4µm without secondary polishing. This tangential cutting strategy also extends tool life by up to 30% compared to orthogonal methods.

Efficiency Gains Through Integrated Workflows and Reduced Handling

5 Axis CNC Machining revolutionizes production efficiency by consolidating multiple operations into a single workflow. This integration directly addresses key bottlenecks: lengthy setups and excessive handling.

Reduction in setup and cycle times through single-setup machining

By machining complex parts in one clamping, modern 5-axis systems eliminate multi-stage processes. Analyses of high-precision workflows show 40–50% faster cycle times due to uninterrupted toolpaths. Maintaining ±0.01mm tolerances while rotating the workpiece further minimizes non-productive tool retractions.

Eliminating multiple fixturing stages to boost throughput

Traditional CNC methods often require 3–4 fixtures for intricate parts, introducing delays and alignment errors. 5-axis technology removes these steps entirely—enabling one medical implant manufacturer to cut fixturing operations by 85% while improving positional accuracy by 30% (2023 machining benchmarks).

Faster material removal rates with consistent tool engagement

Simultaneous axis control keeps tools at optimal cutting angles, allowing 20–35% deeper cuts without vibration. This consistent engagement maintains stable chip load across tough materials like titanium alloys and engineered plastics, preventing deflection-related inaccuracies.

Long-term cost savings from reduced labor and downtime

Integrated operations lead to 18–22% lower labor costs and 60% fewer idle machine hours. One aerospace supplier achieved $2.4M in annual savings by reducing tool wear and eliminating secondary finishing stations—highlighting the long-term financial benefits of 5-axis efficiency.

Key Efficiency Metrics

| Factor | 3-Axis CNC | 5-Axis CNC | Improvement |

|---|---|---|---|

| Average setups per part | 4.2 | 1 | 76% |

| Toolpath interruptions | 18/hr | 3/hr | 83% |

| Labor hours/unit | 6.5 | 2.8 | 57% |

Data source: 2024 Advanced Machining Technologies Report

This streamlined workflow architecture positions 5-axis CNC as the backbone of lean, scalable manufacturing operations.

Machining Complex Geometries Across Aerospace, Medical, and Energy Sectors

Machining complex geometries and curved surfaces in aerospace components

The 5 axis CNC machining process makes it possible to create those complex aerodynamic shapes and intricate lattice structures needed for aerospace applications. What sets it apart is how the machine moves across multiple axes at once, letting cutting tools stay at just the right angle even when working with tough materials such as titanium alloys. This results in consistently tight tolerances around plus or minus 0.01 mm for parts like wing ribs and sections of aircraft bodies. Major companies in the industry are now using these capabilities not only because they can shave off about 15 to 20 percent from component weights but also because the structural strength remains intact where it matters most during flights.

Case Study: Turbine blade production using 5-axis simultaneous machining

In gas turbine manufacturing, 5-axis CNC systems eliminate manual repositioning when machining airfoils with internal cooling channels. A recent implementation reduced production cycles by 40% through continuous toolpath execution, simultaneously milling 57° twist angles and 0.3mm-thick trailing edges in nickel superalloys.

Advantages in medical implant manufacturing requiring organic contours

The medical sector relies on 5-axis CNC to machine biocompatible materials like PEEK into patient-specific implants with anatomical accuracy. Dental prosthetics and spinal fusion cages requiring submillimeter surface smoothness (Ra ¤0.8μm) are produced with 98.7% dimensional accuracy, drastically reducing post-processing needs compared to 3-axis alternatives.

The Role of CAD/CAM and Smart Programming in 5 Axis CNC Success

Role of advanced CAD/CAM software in 5-axis path optimization

The right CAD/CAM software makes all the difference when turning those complicated 3D models into paths that avoid collisions and maintain high precision during machining. Modern systems can handle around a dozen different tool geometry factors plus material characteristics, calculating just how much tilt and rotation is needed at intervals as small as thousandths of a second. What this means in practice is about 25 to 40 percent less tool bending, which keeps everything running smoothly with consistent cutting loads throughout the job. Manual programming simply can't match this kind of precision and reliability anymore.

Trend: Integration of AI-driven toolpath simulation in 5-axis programming

Simulation tools powered by artificial intelligence cut down on programming time about half what it used to be, plus they catch mistakes before they happen around 99 point something percent of the time. These machine learning systems look at past performance data and constantly monitor vibrations through sensors, then tweak feed rates and cutting speeds automatically without needing constant manual input. Industry reports coming out last year show that this kind of intelligent programming makes getting good results on the first try much more likely, especially when dealing with complicated components such as those found in jet engine parts or surgical devices where multiple axes need to work together precisely during manufacturing.

FAQ

What is 5-axis CNC machining?

5-axis CNC machining is an advanced manufacturing process that uses computer-controlled machines to move cutting tools along five different axes simultaneously, enabling precise machining of complex shapes with high efficiency.

How does 5-axis CNC improve accuracy?

By synchronizing all axes during the cutting process, 5-axis CNC machining maintains optimal tool-to-workpiece alignment, achieving tighter tolerances and improving surface finish quality compared to traditional methods.

What are the key advantages of trunnion and swivel-rotary configurations?

Trunnion configurations are best suited for heavy components, offering high repeatability. Swivel-rotary designs excel at producing complex organic shapes, offering precise angular accuracy.

How does motion control technology enhance precision in 5-axis CNC machining?

Advanced motion control features like brushless servo motors and adaptive vibration damping ensure precise execution, even at high speeds, by adjusting for tool deflection and compensating for thermal drift errors.

What role does CAD/CAM software play in 5-axis CNC machining?

CAD/CAM software is crucial for optimizing toolpaths, avoiding collisions, and maintaining high precision by calculating tilt and rotation intervals as small as thousandths of a second.