Architectural Differences: How U-, G-, and V-Series 5-Axis Machining Centers Achieve Motion

Trunnion-Based (U-Series), Rotary-Table (G-Series), and Swivel-Head (V-Series) Kinematic Designs

How a 5-axis machining center is built mechanically really affects where it places the workpiece and tool, which in turn impacts how stiff, accurate, and appropriate for certain jobs the machine will be. The U-Series machines work with what's called trunnion-based kinematics, basically spinning parts around two perpendicular axes using a solid cradle attached to the table. For G-Series models, they go another route altogether by employing rotary tables that move the workpiece under a fixed, super stiff spindle setup. Then there are the V-Series systems that take yet another approach with their swivel head design. These let the spindle rotate across two different axes while keeping the table completely still. All three configurations manage to achieve genuine simultaneous 5-axis movement, though each comes with its own pros and cons. Trunnion systems stand out for their exceptional stiffness and ability to dampen vibrations, supporting about +/- 2 microns of repeatability. They can also handle roughly 20% more cutting force compared to similar rotary table or swivel head setups as per recent analysis from Machine Tool Reports in 2024.

Impact on Part Accessibility, Tool Clearance, and Collision-Free 5-Axis Machining

The way a machine moves around determines how far it can reach into parts, what kind of space there needs to be between tools and components, and whether those paths will run without hitting anything. Take U-Series trunnion systems for instance these designs cut down on long extensions from the machine body and create shorter stiffer cutting paths which works really well when dealing with delicate thin walled aerospace parts that cant afford much bending during machining. When looking at G-Series rotary tables they shine particularly bright in situations where multiple sides of a component need machining. Instead of constantly moving fixtures around, operators simply rotate the part itself this cuts down on wasted time between cuts and boosts overall productivity. Some automotive factories have seen their production cycles drop by as much as 30% compared to old methods where everything had to be set up separately. For V-Series swivel head machines, their real strength lies in getting into those hard to reach areas deep inside molds or dies where vertical walls dominate the geometry. These machines become almost essential whenever nearly straight wall surfaces need precise machining. What ties all these different system types together is that better movement design lets machinists use shorter tools. Shorter tools mean faster spinning spindles, less shaking during operation, and surfaces that come out smoother right off the machine often good enough quality wise that no extra polishing or grinding steps are needed afterward.

Key Performance Metrics for 5-Axis Machining Centers: Speed, Power, and Capacity

Evaluating 5-axis machining centers requires balancing three interdependent performance dimensions: speed capabilities, power delivery, and physical capacity. These metrics collectively determine whether a machine can reliably produce parts at required tolerances, material removal rates, and volumes”without compromising precision or process stability.

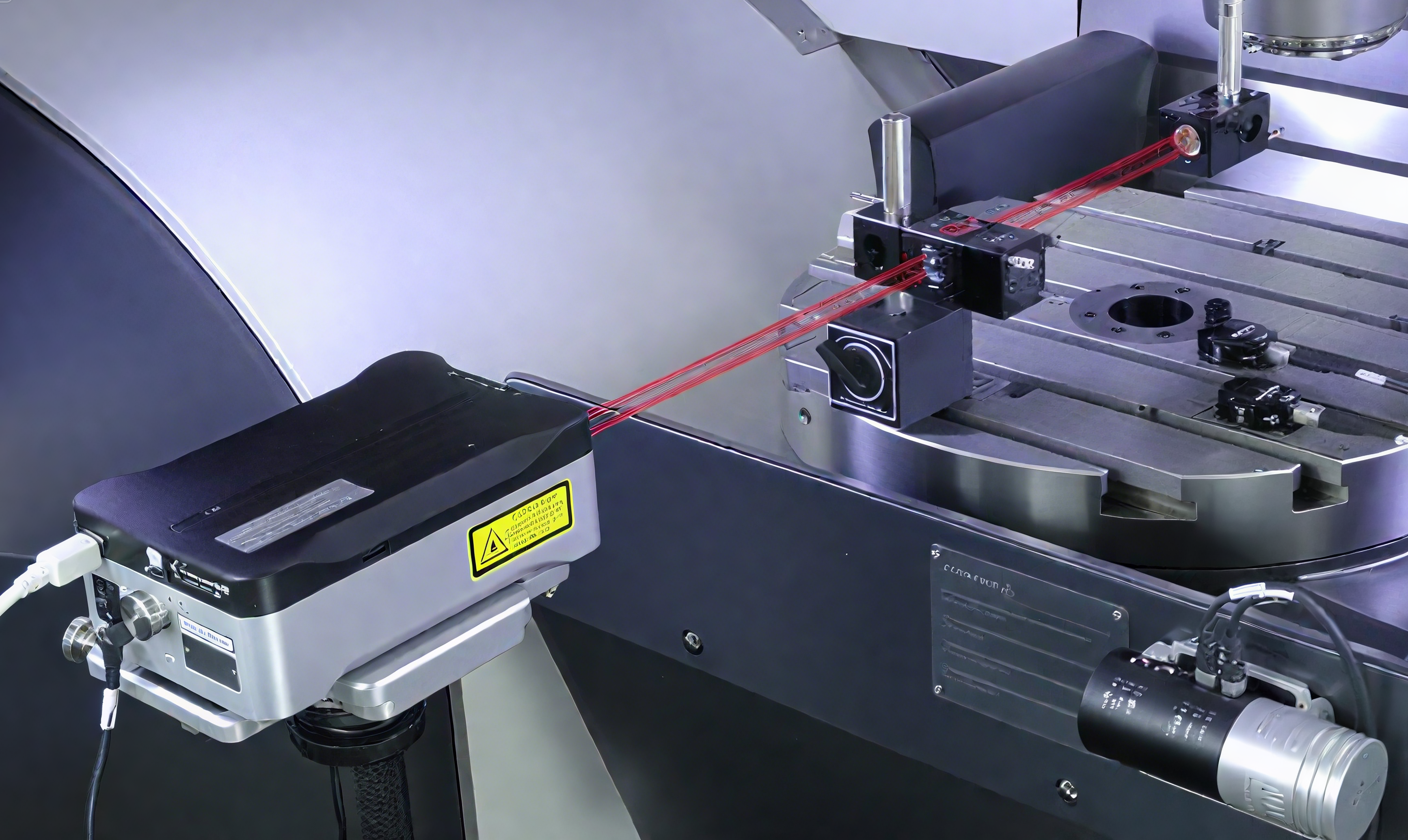

Spindle Speed, Torque, and BMT Compatibility Across Series

How well a spindle performs really affects how productive we can be with different materials. When working with stuff like aluminum or carbon fiber composites, going above 20,000 RPM makes a big difference in how fast material gets removed, which is super important for those delicate aerospace thin wall components. On the flip side, when cutting tougher metals such as titanium or Inconel, machines need slower speeds but lots of torque power, sometimes up to around 250 Nm depending on setup, so they don't bog down mid cut. The Base Mounting Technology compatibility matters too because it creates that solid connection between the tool holder and spindle itself. This helps keep things stable, reducing any wobble to less than 0.003 mm and keeping everything aligned within about +/- 0.01 mm even at top speeds during intricate contours. Thermal management cant be ignored either. Liquid cooling systems stop heat buildup from messing with dimensions by more than 0.005 mm over long runs, something crucial when manufacturing large or complicated parts where precision counts.

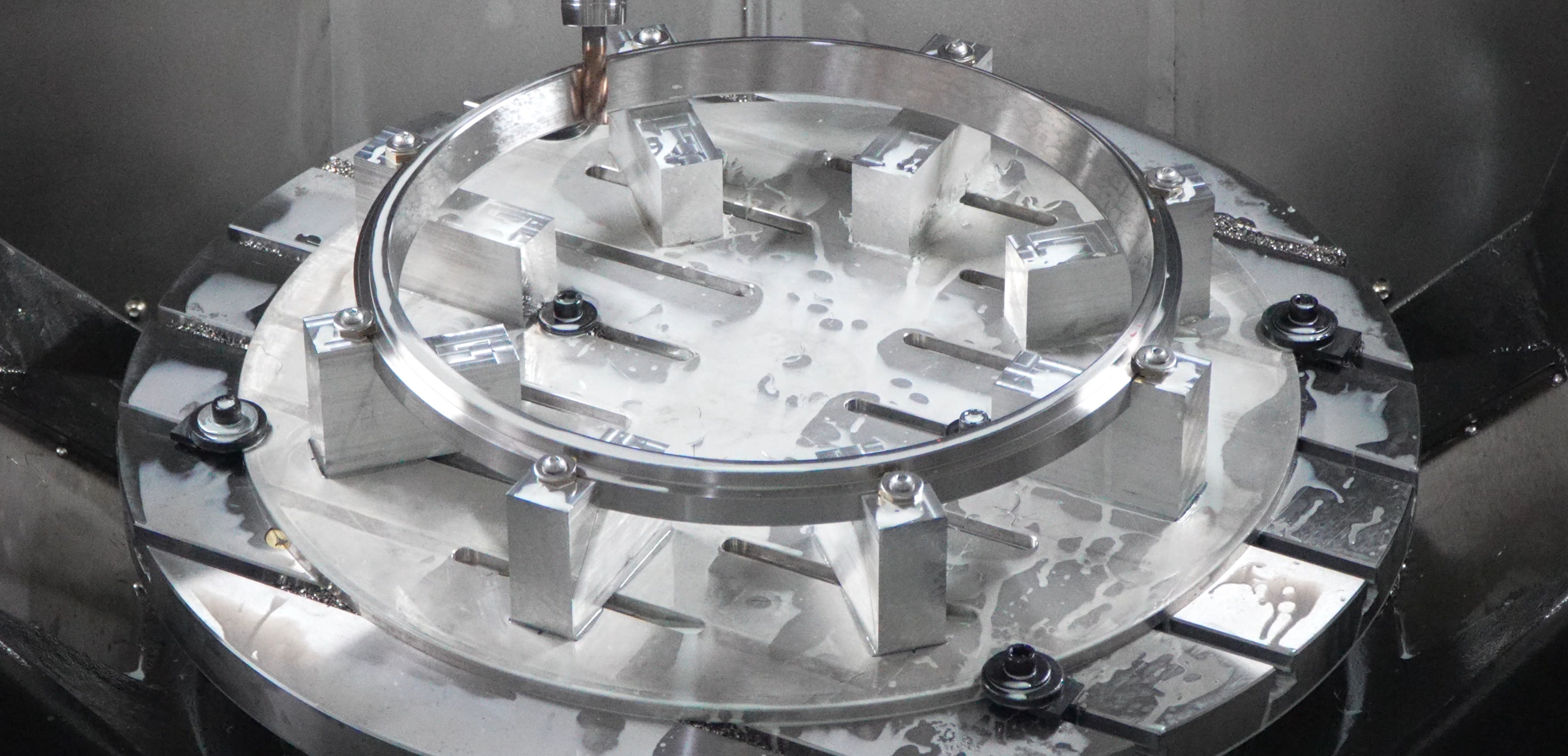

Worktable Size, Payload, and Axis Travel ” Matching 5-Axis Machining Centers to Part Scale

The physical size and strength capabilities of machinery determine what parts can actually be handled in practice. Small worktables around 600 by 400 millimeters are great for things like medical implants where precision matters most, while bigger tables measuring over 1200 by 800 millimeters handle heavy duty stuff such as airplane parts or car body molds. When it comes to payload capacity, machines usually range between 500 kilograms to 2000 kilograms, but they need to carry at least 25% more than the actual part weight to stay stable when moving across all five axes at once. How far each axis can move determines the total space available for machining operations. Machines with X/Y/Z movements past 1000 mm let manufacturers finish big dies or turbine casings without having to stop and reposition parts. Getting the machine size wrong has real consequences too small machines lead to about 30% more setup time which means higher labor costs and more chances for mistakes. Big machines just take up unnecessary space and consume extra power. A good rule of thumb is to pick equipment based on the part dimensions plus about 15% extra room so tools can move freely without crashing into anything when working on complicated shapes.

Application-Specific Strengths of Leading 5-Axis Machining Centers

Makino U-Series: High-Speed Precision for Aerospace Thin-Wall Components

The U-Series machine uses trunnion based kinematics along with a special vibration damping system that keeps things stable even during those intense high speed cuts on aerospace parts with thin walls. The way it distributes weight throughout the machine body helps maintain position accuracy down to around plus or minus 5 microns while working with aluminum at spindle speeds over 20 thousand RPM. This level of precision makes all the difference when producing turbine blades and duct assemblies where walls can be less than 0.8 mm thick. What really sets this apart though is the built in thermal compensation feature. These smart algorithms constantly adjust for temperature changes both in the environment and from the machining process itself. Manufacturers report seeing scrap rates drop by as much as 40% compared to regular five axis machines when dealing with tricky materials such as 7075-T6 aluminum or carbon fiber reinforced plastic laminates that are particularly sensitive to heat variations.

DMG MORI G-Series: Thermal Stability and Automation Integration for High-Mix Production

The G-Series is built specifically for manufacturing environments where product variety matters but volumes stay moderate. It features direct drive rotary tables paired with balanced liquid cooling throughout both the bed and column area. Thermal stability stays within half a degree Celsius even when running non-stop day after day, which cuts down on measurement drift when moving from one material to another like going from titanium grade 5 to inconel 718 parts. With standard robotic connections, automatic pallet changers, and built-in measuring systems, this setup enables completely hands-off production for intricate medical devices or car component prototypes. Setup changes take about 40% less time than before, while initial quality passes hit around 98%. That kind of performance makes all the difference for shops dealing with over 200 different part types each year.

Yamazaki Mazak V-Series: Adaptive Control and Intelligent Features for Mold & Die Machining

The V-Series combines swivel head mechanics with smart adaptive controls that handle the tough requirements of working with hardened steel molds and dies. When cutting through steels as hard as 65 HRC, the machine constantly watches for tool deflection thanks to built-in strain sensors and analysis of spindle current. This lets it adjust feed rates on the fly during heavy cuts, which means tools last about 35% longer and surfaces stay smooth down to 0.01 mm Ra or better. Special algorithms figure out safe paths before any undercutting or cavity work starts, stopping those expensive crashes that can cost over $50,000 in deep draw die shops. And with on machine probing, core shapes get checked right in the middle of production, so most injection mold parts don't need separate inspections anymore. This cuts down wait times between jobs and makes tracking quality throughout manufacturing much easier for shop managers.

Frequently Asked Questions

What are the main differences between U-, G-, and V-Series 5-axis machining centers?

The main differences lie in their kinematic designs: U-Series uses a trunnion-based approach, G-Series employs rotary tables, and V-Series features a swivel head design. Each configuration has unique advantages in terms of stiffness, tool accessibility, and applicability to specific machining tasks.

Why is tool clearance crucial in 5-axis machining?

Tool clearance is essential to ensure collision-free operation and optimum accessibility to different part features. It influences how a machine can reach tight spaces or complex surfaces without causing damage or requiring additional setup time.

How does thermal stability affect 5-axis machining performance?

Thermal stability is critical for maintaining dimensional accuracy and process reliability. Temperature fluctuations can lead to expansion or contraction of machine parts, impacting precision and increasing potential for errors, especially in high-speed, high-precision tasks.

Which industries benefit most from each series of machining centers?

Industries like aerospace benefit from the U-Series due to its high precision and speed for thin-wall components. The G-Series is advantageous for sectors requiring high-mix production, such as medical device manufacturing. The V-Series excels in mold and die making, dealing with hard materials requiring adaptive control.