For manufacturers serving aerospace, medical devices, energy, and high-precision engineering, the question is no longer what a 5 axis CNC machine can do—but whether the investment truly delivers measurable returns. With machine prices significantly higher than traditional equipment, understanding the 5 axis CNC machine cost, long-term operating expenses, and real-world ROI is critical before making a purchasing decision.

This article provides a structured 5 axis CNC machining cost breakdown, examines hidden ownership costs, and explains when a 5 axis CNC machine investment becomes not only justified, but essential.

Understanding the Initial 5 Axis CNC Machine Cost

The most visible component of ownership is the upfront purchase price. Depending on configuration, brand, and application focus, the 5 axis CNC machine price typically falls into the following ranges:

| Machine Class | Typical Price Range |

|---|---|

| Entry-level trunnion type | USD 180,000 – 300,000 |

| Mid-range production 5 axis CNC machine | USD 300,000 – 600,000 |

| High-end aerospace / medical systems | USD 600,000 – 1,200,000+ |

While this initial 5 axis CNC machine cost may appear steep compared to 3-axis or 4-axis alternatives, purchase price alone does not reflect the full economic picture.

Tooling, Fixturing, and Setup: Where 5 Axis Saves Money

One overlooked advantage in any 5 axis CNC machine investment is the dramatic reduction in tooling and fixturing complexity. Because parts can be machined in a single setup:

-

Custom fixtures are reduced by up to 60–70%

-

Manual re-clamping and re-alignment are eliminated

-

Setup time drops by 50–80% for complex parts

For manufacturers comparing 5 axis CNC vs 3 axis cost, these savings often offset a large portion of the initial price difference within the first year of production.

Operating Costs: Power, Tool Wear, and Maintenance

Beyond purchase price, the total cost of ownership CNC machine must include ongoing operating expenses.

Power and Utilities

Modern 5 axis systems are more energy-efficient than legacy machines, but higher spindle power and axis motion increase electricity consumption by approximately 10–15% compared to 3-axis machining.

Tooling and Tool Life

Advanced tool orientation significantly improves cutting conditions:

-

Tool life increases 20–40% in titanium and Inconel

-

Reduced chatter lowers scrap and rework

-

Adaptive toolpaths minimize edge wear

This directly lowers the cost of 5 axis CNC machining over sustained production runs.

Maintenance and Calibration

Annual maintenance and calibration costs are higher due to:

-

Rotary axis calibration

-

Thermal compensation systems

-

Multi-axis kinematic verification

However, these systems also reduce geometric drift, protecting tight tolerances and preserving long-term accuracy.

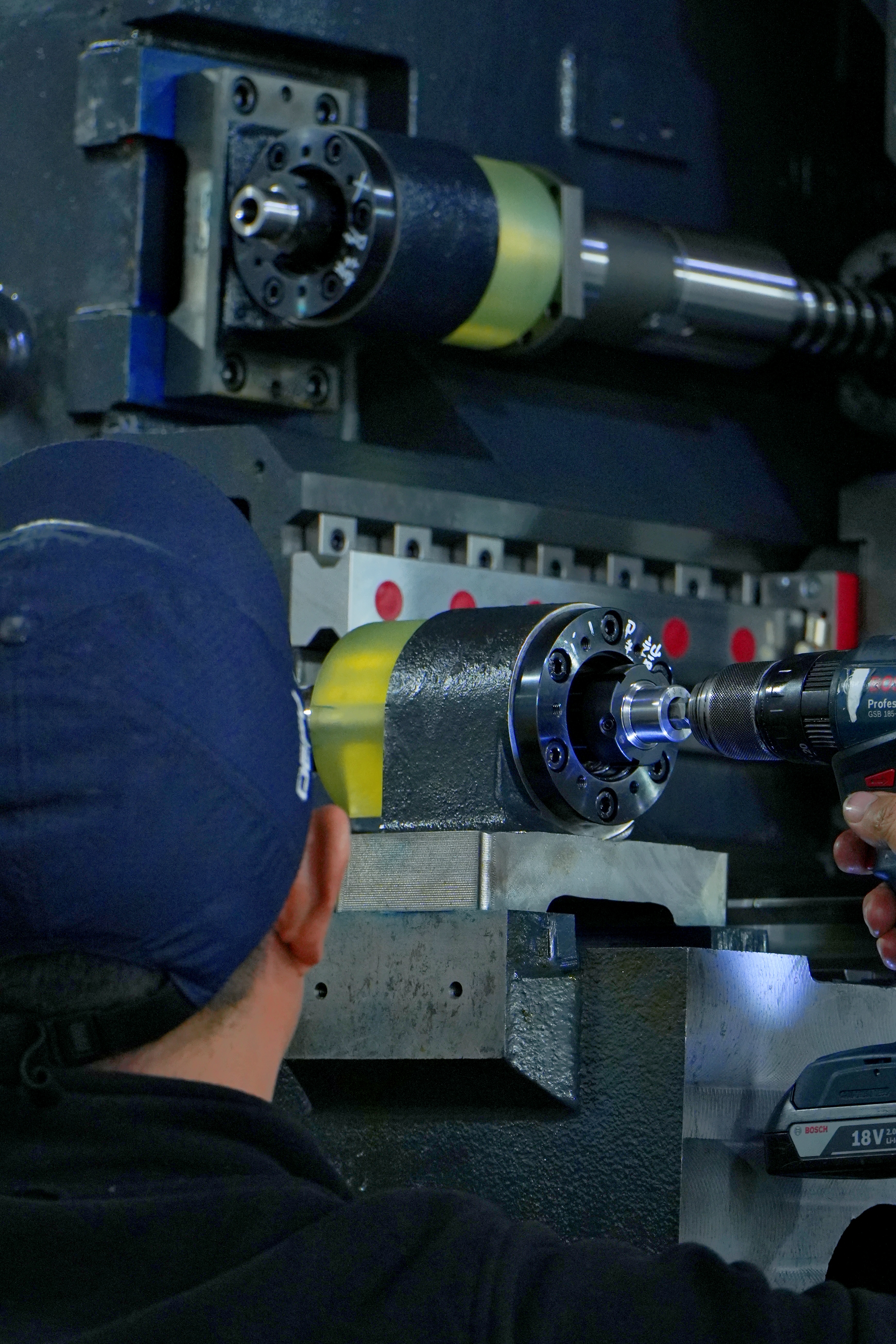

Labor Efficiency and Automation Advantages

Labor costs are a decisive factor when evaluating is a 5 axis CNC machine worth it. Single-setup machining allows:

-

Fewer operator interventions

-

Lights-out and unattended machining

-

Faster part qualification and inspection

Shops integrating automation frequently report 30–50% labor cost reduction per part, especially in aerospace and medical production environments.

ROI Analysis: When Does a 5 Axis CNC Machine Pay for Itself?

A realistic 5 axis CNC machine ROI model considers:

-

Setup time reduction

-

Scrap rate reduction (often 25–40%)

-

Increased spindle utilization

-

Expanded part complexity capability

For manufacturers producing complex geometries, break-even commonly occurs within 18–36 months, depending on part mix and production volume.

In aerospace and medical device manufacturing, the ROI timeline is often shorter due to:

-

Higher part value

-

Stricter tolerance requirements

-

Reduced compliance risk

Industry-Specific Value: Aerospace and Medical Manufacturing

Aerospace Applications

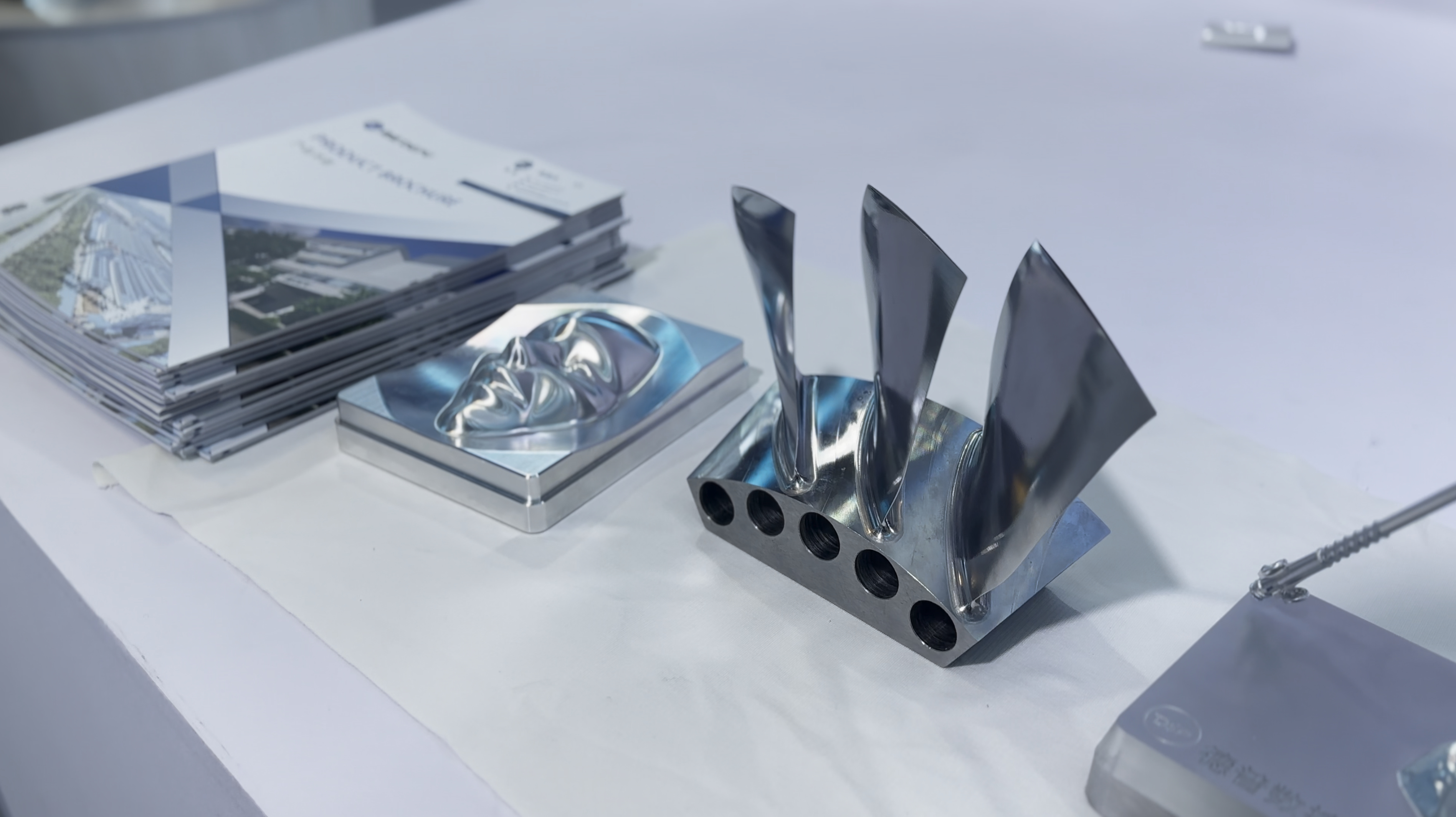

A 5 axis CNC machine for aerospace manufacturing enables:

-

Monolithic structural components

-

Weight reduction through optimized geometry

-

Consistent fatigue-resistant surface finishes

These capabilities directly reduce lifecycle costs beyond machining alone.

Medical Device Production

A 5 axis CNC machine for medical devices supports:

-

Patient-specific implants

-

Sub-micron surface control

-

Full traceability for regulatory compliance

In these sectors, the 5 axis CNC machine investment is often a requirement—not an option.

Hidden Costs Buyers Often Miss

When evaluating how much does a 5 axis CNC machine cost, buyers frequently underestimate:

-

CAM software and post-processor development

-

Operator training and process validation

-

Metrology upgrades for complex geometry inspection

Planning for these costs upfront ensures realistic ROI expectations and smoother implementation.

Conclusion: Is a 5 Axis CNC Machine Worth It?

For simple prismatic parts, a 3-axis solution may remain sufficient. But for manufacturers facing complex geometry, tight tolerances, and high-value materials, a high precision 5 axis CNC machining system delivers measurable financial and technical advantages.

When evaluated through total cost of ownership and long-term productivity, the answer to is a 5 axis CNC machine worth it is increasingly clear: for critical manufacturing, it is not an expense—it is a competitive necessity.

FAQ

1. Is a 5 axis CNC machine always more expensive to operate?

Not necessarily. While tooling and maintenance can be higher, reduced setup time, lower scrap rates, and faster production often result in lower overall operating costs.

2. How long does it take to see ROI on a 5 axis CNC machine?

ROI timelines vary, but many manufacturers see returns within 1–3 years through labor savings, higher throughput, and access to more complex, higher-margin parts.

3. Does a 5 axis CNC machine reduce labor costs?

Yes. Single-setup machining and automation-ready workflows reduce manual repositioning, inspection, and rework, lowering labor dependency.

4. Which industries benefit most from investing in 5 axis CNC machines?

Aerospace, medical devices, energy, and precision tooling industries benefit the most due to their tight tolerances, complex geometries, and strict quality requirements.