How Material Properties Define Accuracy, Surface Integrity, and Process Stability in Advanced CNC Machining

In high-precision manufacturing, machining performance is never determined by machine capability alone. Material choice plays a decisive role in defining achievable tolerances, surface finish, tool life, and long-term component reliability. As industries such as aerospace, medical devices, and energy continue to demand tighter tolerances and more complex geometries, understanding how different materials behave under precision machining has become a strategic necessity rather than an academic exercise.

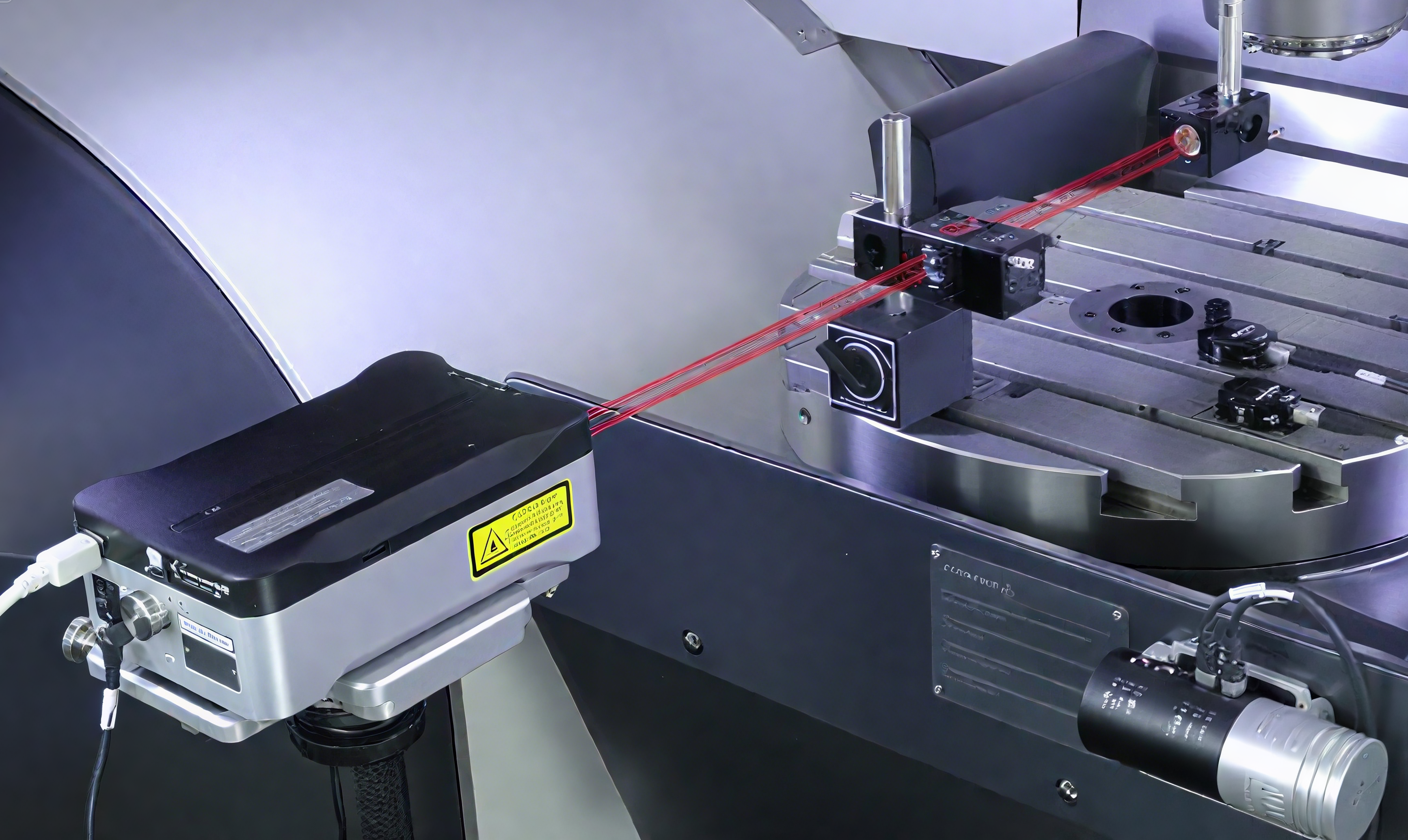

Advanced 5-axis CNC machining platforms—designed with high rigidity structures, full closed-loop feedback, and thermal stability systems—provide the foundation. However, it is the interaction between material characteristics and machining dynamics that ultimately determines success.

Material Properties That Directly Influence Machining Precision

Every engineering material responds differently to cutting forces, heat generation, and vibration. The most critical properties affecting precision machining include:

-

Thermal conductivity – influences heat accumulation and dimensional stability

-

Hardness and work-hardening behavior – affects tool wear and cutting consistency

-

Elastic modulus – impacts part deflection during machining

-

Chemical reactivity – determines tool-material interaction at high temperatures

In high-accuracy environments, even minor deviations in these properties can shift machining outcomes from acceptable to scrap.

Titanium Alloys: Precision Under Thermal Stress

Titanium alloys such as Ti-6Al-4V are widely used in aerospace structures and medical implants due to their high strength-to-weight ratio and corrosion resistance. However, titanium’s low thermal conductivity causes heat to concentrate at the cutting zone, increasing the risk of tool wear, surface damage, and dimensional drift.

With modern 5-axis CNC machining, continuous tool engagement and optimized cutting angles reduce intermittent contact and localized overheating. High-rigidity machine structures combined with spindle torque adaptability allow manufacturers to maintain micron-level dimensional stability, even when machining thin-walled aerospace brackets or patient-specific implants.

Typical results observed in production environments include:

-

Stable tolerances below ±5 µm

-

Surface finishes improved by over 60% compared to conventional 3-axis setups

-

Tool life extended through controlled heat dissipation

Nickel-Based Superalloys: Managing Work Hardening and Cutting Forces

Nickel-based superalloys such as Inconel 718 are essential for turbine components, energy systems, and high-temperature aerospace applications. These materials are characterized by extreme strength, rapid work hardening, and high cutting resistance.

Precision machining of these alloys demands:

-

Adaptive toolpath strategies to prevent work hardening

-

High spindle torque with vibration suppression

-

Stable thermal control throughout long machining cycles

Simultaneous 5-axis machining enables continuous contouring without re-clamping, minimizing cumulative error while maintaining consistent tool engagement. Manufacturers consistently achieve sub-0.01 mm accuracy on complex geometries while preserving surface integrity critical to fatigue resistance.

Aluminum Alloys: Speed, Stability, and Repeatability

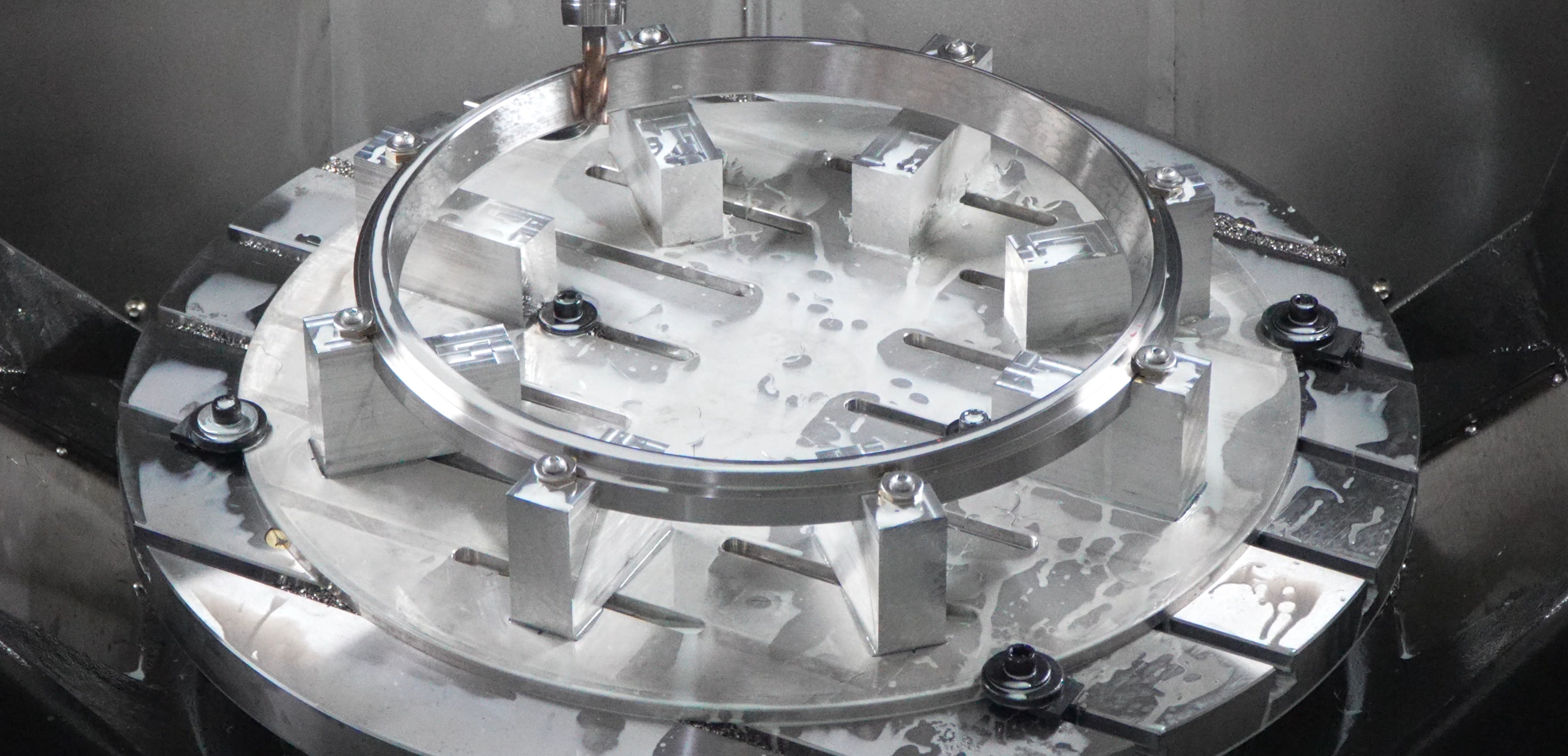

While aluminum alloys are often considered “easy to machine,” aerospace-grade aluminum introduces its own challenges when extreme precision is required. Thin-walled structures, large monolithic parts, and tight flatness specifications demand exceptional machine rigidity and positional repeatability.

Advanced CNC platforms equipped with high-speed spindles and full closed-loop control allow:

-

High-speed material removal without chatter

-

Repeatability rates exceeding 99.9% in serial production

-

Consistent surface finishes suitable for aerodynamic components

This capability enables the consolidation of multi-part assemblies into single monolithic structures, reducing weight while improving structural integrity.

Composite and Hybrid Materials: Surface Integrity as a Priority

Carbon-fiber composites and hybrid material stacks are increasingly common in aerospace and medical applications. Unlike metals, composites are vulnerable to delamination, fiber pull-out, and subsurface damage during machining.

Precision machining solutions rely on:

-

Optimized cutting angles via multi-axis positioning

-

Controlled cutting forces to prevent layer separation

-

Stable machine dynamics to eliminate micro-vibration

The result is cleaner edge quality, reduced post-processing, and higher functional reliability for safety-critical components.

Why Material-Matched Machining Strategy Determines ROI

Across industries, the data points to a clear conclusion: precision machining performance is inseparable from material-specific process design. Matching machine configuration, spindle characteristics, control algorithms, and cutting strategy to material behavior delivers measurable returns:

| Performance Metric | Material-Optimized 5-Axis Machining |

|---|---|

| Dimensional accuracy | Up to 60% improvement |

| Surface roughness (Ra) | 50–75% reduction |

| Tool life | 2–3× extension |

| Scrap rate | Reduced by 15–30% |

| Cycle time | Shortened by 30–45% |

These gains are particularly impactful in aerospace and medical manufacturing, where failure is not an option and regulatory compliance depends on repeatable precision.

Conclusion: Precision Starts with Material Intelligence

In modern manufacturing, selecting the right material is only the first step. True competitive advantage comes from understanding how that material behaves under precision machining—and deploying CNC systems capable of responding intelligently to those behaviors.

As tolerances tighten and part geometries grow more complex, material-aware 5-axis CNC machining is no longer optional. It is the foundation of consistent quality, regulatory compliance, and long-term operational performance.

FAQ

How does material choice affect precision machining performance?

Material properties such as thermal conductivity, hardness, elastic modulus, and chemical reactivity directly influence machining accuracy, surface finish, and dimensional stability. Materials like titanium and nickel-based superalloys generate high cutting heat and cutting forces, requiring advanced 5-axis CNC machining with thermal compensation and optimized tool engagement to maintain micron-level precision.

Why is 5-axis CNC machining critical for difficult-to-machine materials?

5-axis CNC machining allows continuous, multi-directional tool engagement, which reduces re-clamping errors, minimizes tool deflection, and controls heat concentration. This is especially important for materials like titanium, Inconel, and composites, where interrupted cutting or poor tool angles can lead to work hardening, surface damage, or dimensional distortion.

Can the same CNC machine deliver equal precision across different materials?

No. Precision outcomes depend on how well the machine configuration matches material behavior. High-rigidity structures, spindle torque options, full closed-loop feedback systems, and adaptive toolpaths must be selected and tuned according to the material being machined to achieve consistent results.

How does material choice impact surface finish in precision machining?

Materials with poor thermal conductivity or high hardness tend to increase vibration and surface roughness if not properly controlled. With material-matched 5-axis machining strategies, surface roughness (Ra) can be reduced by 50–75%, eliminating secondary polishing and improving functional performance in aerospace and medical components.

Which industries benefit most from material-optimized 5-axis machining?

Industries where failure is unacceptable—such as aerospace, medical devices, and energy—benefit the most. In these sectors, material-optimized 5-axis CNC machining ensures tight tolerances, reliable surface integrity, regulatory compliance, and long-term operational safety.