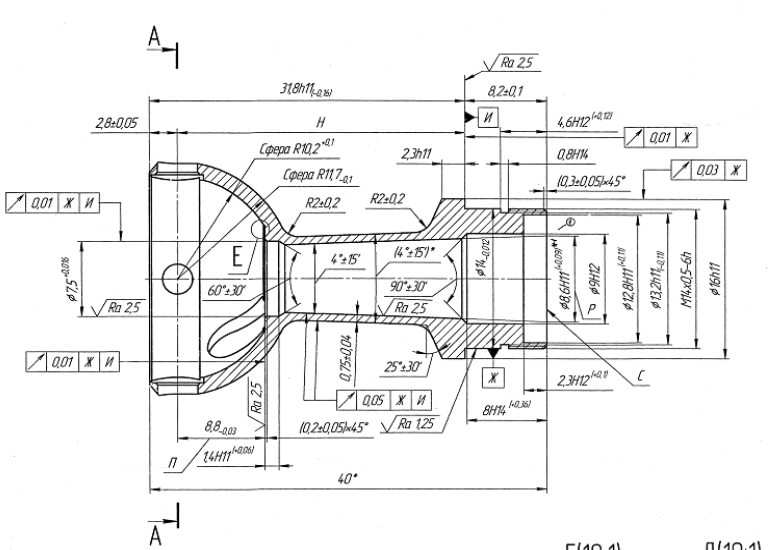

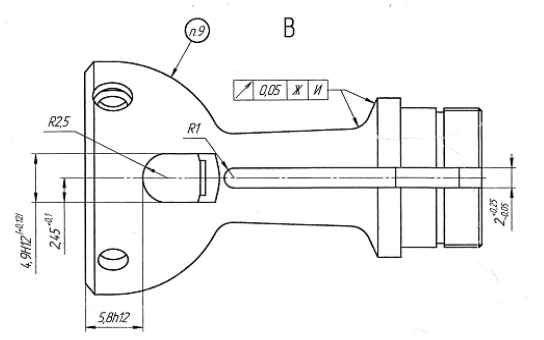

The G300 precision machining center is designed G300 machine parts to meet these requirements. It combines a rigid mechanical structure, a high-performance motion control system, and a precision-oriented process design, enabling the G300 to achieve stable and repeatable micron-level machining accuracy, even for complex and high-precision parts.

This article explains how the G300 achieves micro-level precision, the key technical advantages behind its performance, and how engineering drawings are used to validate real-world machining capability.Precision machining starts with mechanical stability. The G300 features a high-rigidity machine structure designed to minimize vibration and deformation during cutting.The G300 employs a high-precision motion transmission system, ensuring accurate and repeatable axis movement.

The DEPU G300 Cradle Type Five-Axis Vertical Machining Center is engineered to achieve micron-level precision in demanding high-end machining applications. Through its gantry-type symmetrical structure, high-performance DD cradle rotary table, precision ball screws, and full closed-loop control system, the G300 ensures exceptional rigidity, stability, and accuracy. This article explores the key technologies and design features that enable the G300 to meet the stringent requirements of industries such as aerospace, automotive, and medical equipment manufacturing.

1. Advanced Structural Design for Unmatched Rigidity

The G300 features a gantry-type symmetrical structure, constructed from high-quality cast iron that undergoes dual heat treatments to eliminate residual stress. This design ensures exceptional mechanical stability and minimizes deformation during high-speed cutting operations. The result is a machine capable of maintaining micron-level accuracy even under heavy loads and dynamic conditions.

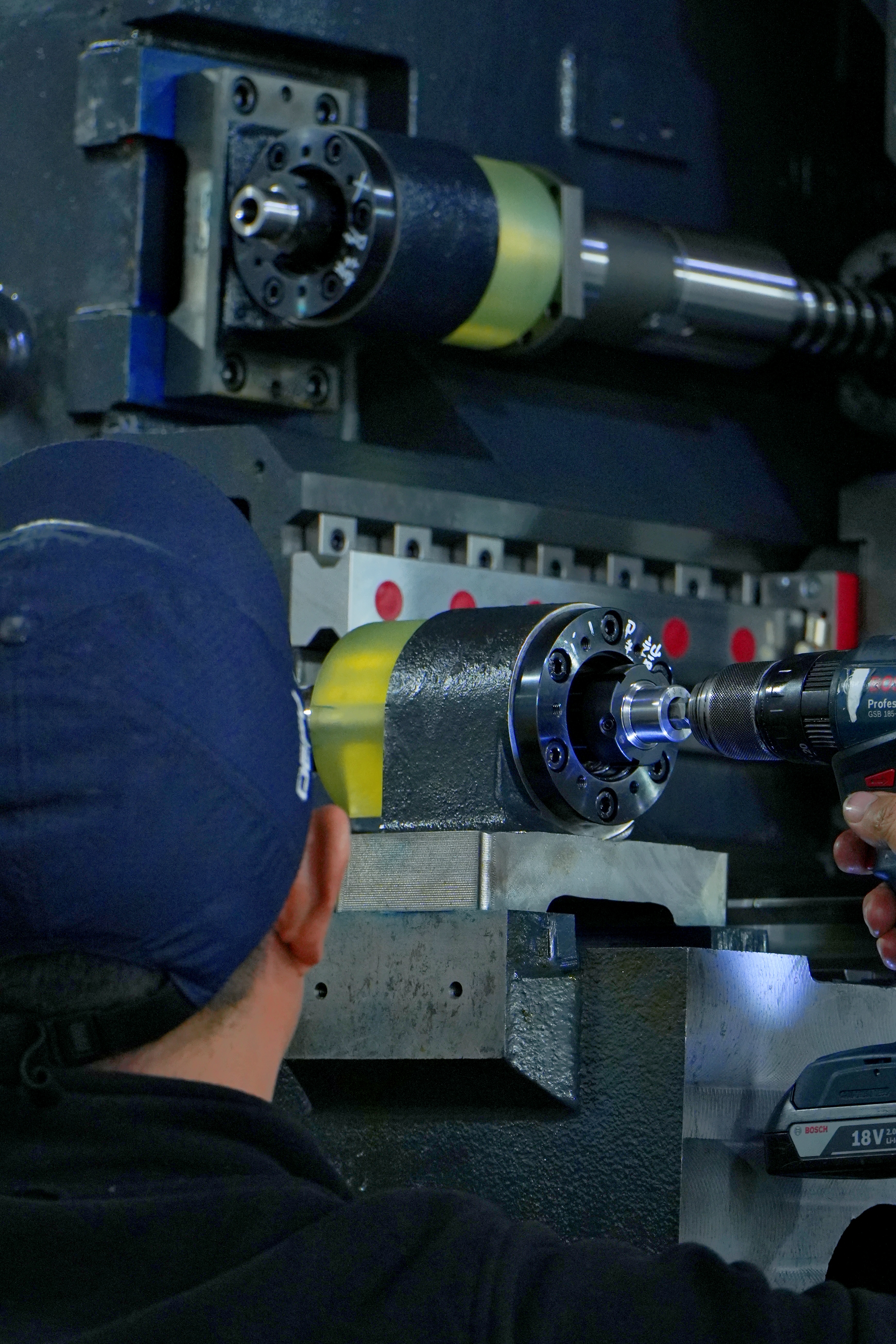

2. High-Performance DD Cradle Rotary Table

At the heart of the G300’s precision is its direct-drive (DD) cradle rotary table, equipped with YRT bearings for superior load-bearing capacity and rotational accuracy. Paired with HEIDENHAIN position feedback devices, the table enables precise angular positioning and smooth motion, critical for complex five-axis machining tasks.

3. Precision Motion Control with Full Closed-Loop Feedback

Every axis of the G300 is fitted with high-precision NSK/THK ball screws and HEIDENHAIN linear encoders, ensuring accurate linear motion and real-time position correction. The full closed-loop control system continuously monitors and adjusts the machine’s movements, guaranteeing long-term accuracy and repeatability.

4. Customizable High-Speed Spindle Options

The G300 offers a range of high-performance electric spindles with speeds up to 24,000 RPM and torque options up to 123.4 N.m. This flexibility allows manufacturers to tailor the machine to specific materials and applications, from aluminum to hardened steels, without compromising precision.

5. Multi-Specification Tool Magazine for Versatility

With optional 24T, 32T, 40T, or 60T tool magazines, the G300 supports diverse machining operations without frequent manual tool changes. This enhances productivity while maintaining the precision required for intricate parts.

6. Application-Ready for High-End Industries

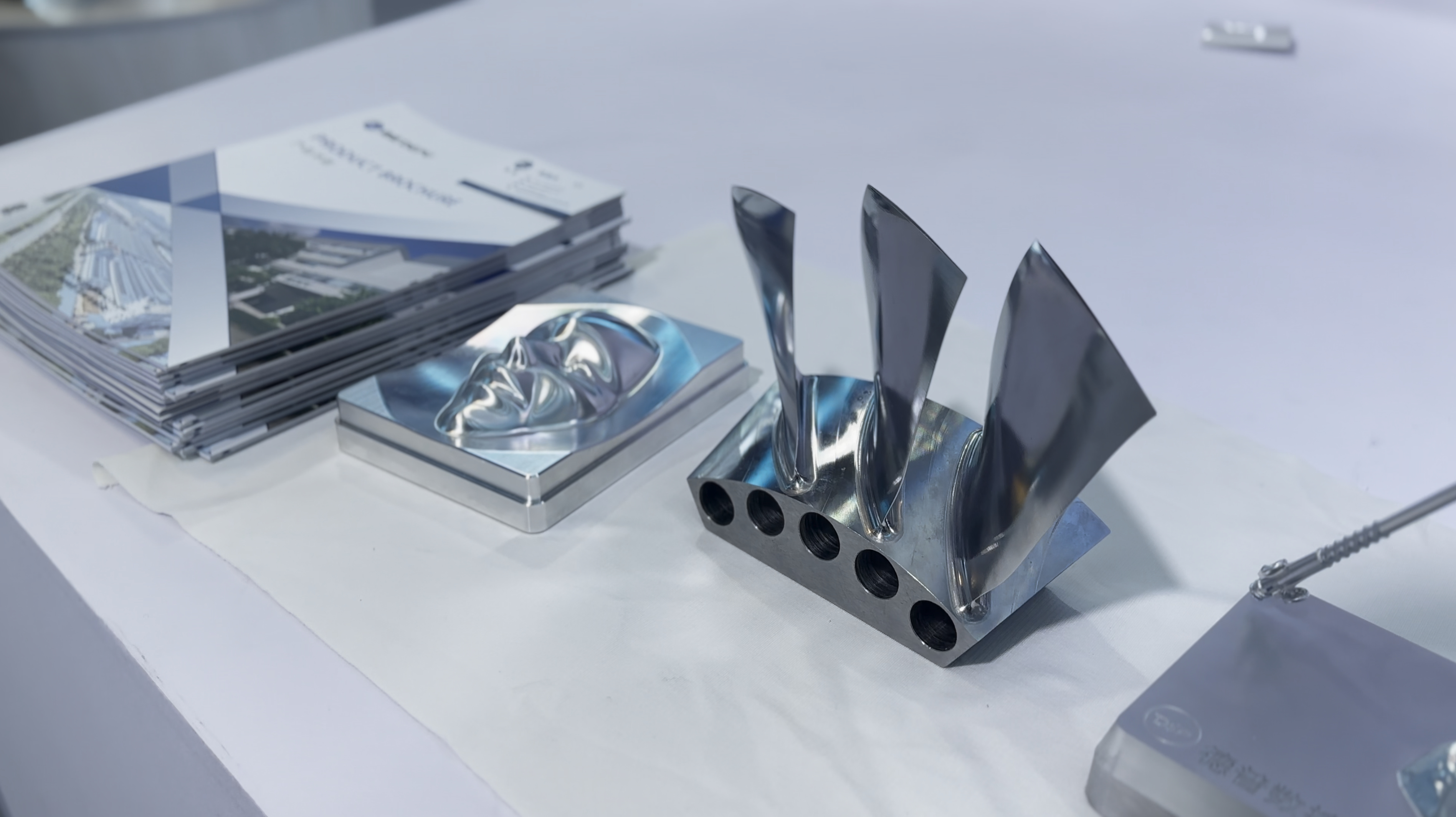

The G300 milling machine is designed to excel in sectors where precision is non-negotiable:

-

Aerospace: Machining turbine blades, structural components, and landing gear parts.

-

Automotive: Producing molds, prototypes, and high-performance engine components.

-

Medical: Crafting implants, surgical instruments, and diagnostic device parts.