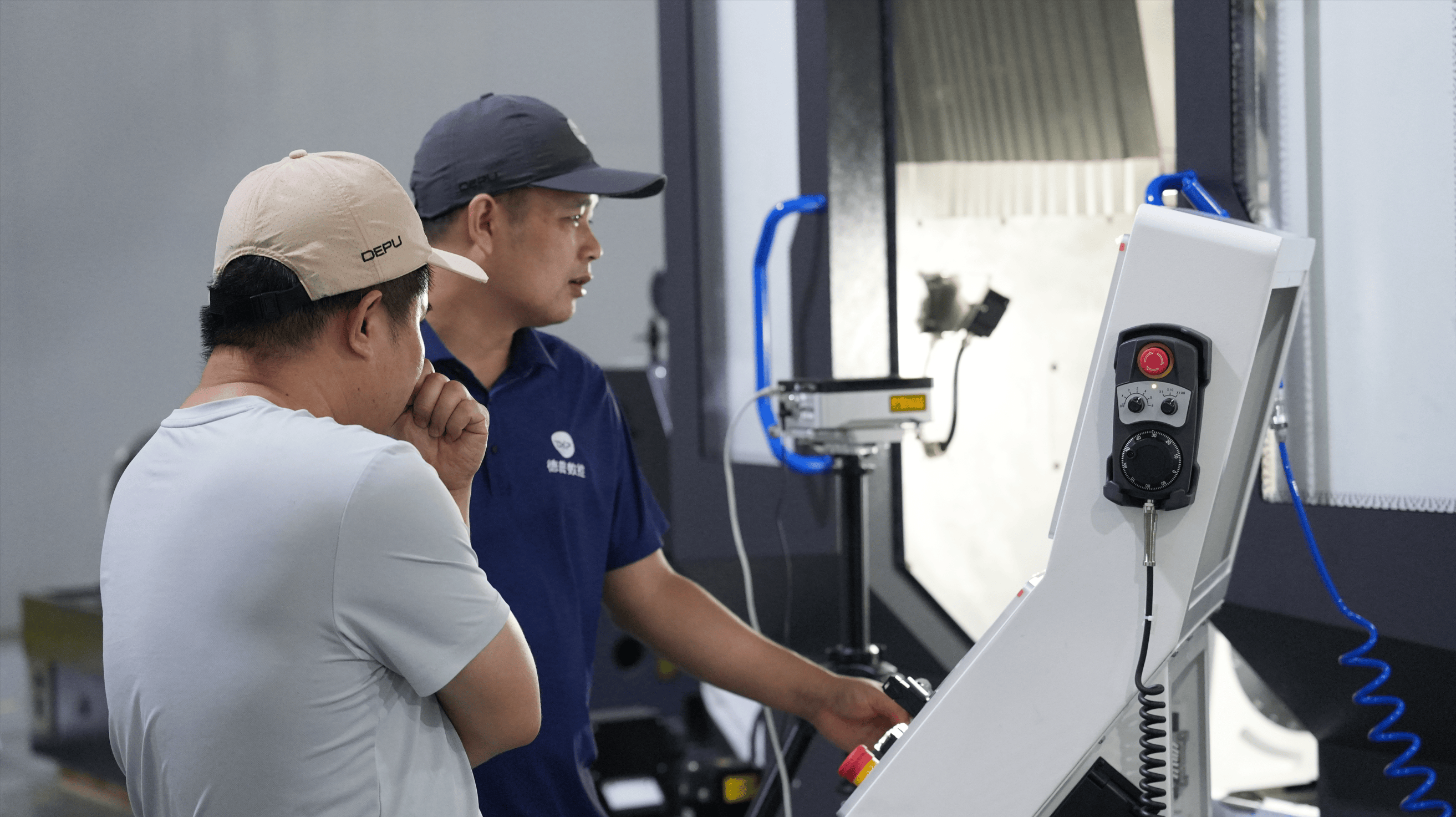

5-axis CNC machining has become indispensable in aerospace, medical, energy, and other high-reliability industries. Its ability to machine complex geometries in a single setup enables tighter tolerances, better surface integrity, and shorter lead times.

However, the advantages of 5-axis machining are not automatic. Many manufacturers invest in advanced 5-axis equipment but fail to realize its full potential due to programming mistakes that compromise accuracy, surface quality, tool life, and even part safety.

This article outlines the most common—and most costly—mistakes to avoid when programming 5-axis CNC machines, drawing from real-world aerospace and medical manufacturing experience. Avoiding these pitfalls is essential for achieving micron-level precision, stable repeatability, and predictable ROI.

1. Treating 5-Axis Programming Like Advanced 3-Axis Machining

One of the most fundamental mistakes is approaching 5-axis programming as an extension of 3-axis logic.

In 3-axis workflows, programmers typically:

-

Lock part orientation

-

Rely on multiple setups

-

Accept datum shifts as unavoidable

In true simultaneous 5-axis machining, this mindset leads to:

-

Over-constrained toolpaths

-

Unnecessary reorientations

-

Missed opportunities for single-setup completion

5-axis machining is not about more axes—it is about continuous coordination of geometry, tool orientation, and cutting forces.

When programmers fail to design toolpaths that fully leverage A- and B-axis motion, they often reintroduce the very errors 5-axis machines are meant to eliminate: cumulative tolerance stack-up, inconsistent surface finish, and extended cycle times.

Best practice:

Program with a “single-datum, full-contour” strategy from the start. The goal should be complete part accessibility and uninterrupted machining wherever possible.

2. Ignoring Tool Orientation Optimization and Lead/Lag Angles

In 5-axis machining, tool orientation is just as critical as tool position.

A common error is maintaining a fixed tool angle throughout complex surfaces. This can result in:

-

Excessive tool deflection

-

Chatter on thin walls

-

Uneven surface roughness

-

Premature tool wear

For difficult materials such as titanium or Inconel, improper lead and lag angles significantly increase cutting forces—often beyond what even high-end spindles are designed to handle.

Why this matters:

-

Tool deflection directly degrades geometric accuracy

-

Surface Ra values increase even when feed rates are reduced

-

Heat concentrates at the cutting edge, accelerating wear

Best practice:

Use dynamic tool orientation that continuously adjusts lead/lag angles to maintain optimal engagement. This allows:

-

Shorter, stiffer tools

-

More consistent cutting forces

-

Improved surface finish (often Ra ≤ 0.4 μm without secondary polishing)

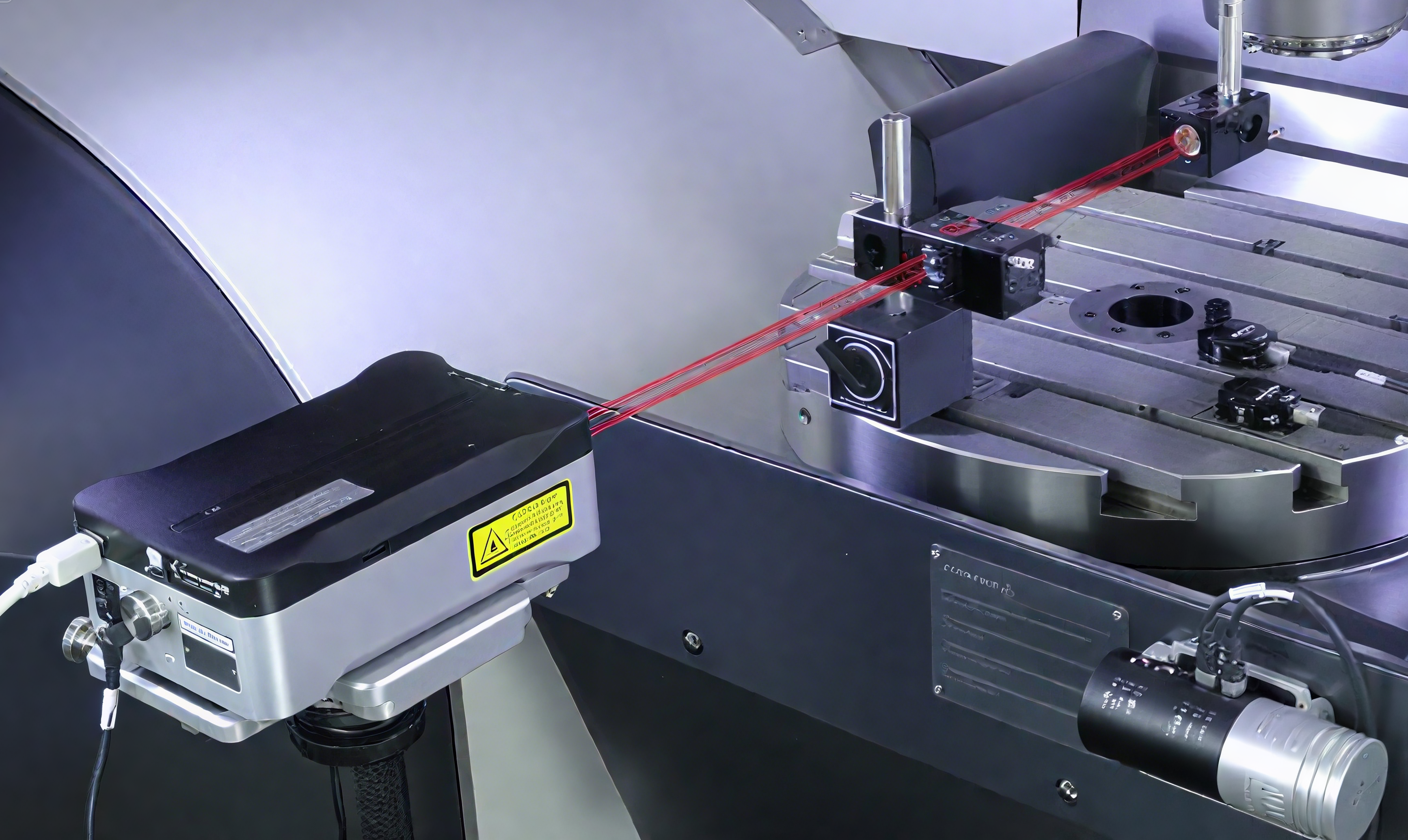

3. Poor Collision Avoidance and Incomplete Machine Simulation

Many 5-axis crashes happen not on the shop floor, but in the CAM environment—because full kinematic simulation was skipped or oversimplified.

Common simulation mistakes include:

-

Ignoring spindle nose and toolholder geometry

-

Failing to model rotary axis limits

-

Overlooking cable wrap or axis singularities

-

Assuming CAM defaults are “safe enough”

In 5-axis machining, even a few degrees of unexpected rotation can cause:

-

Toolholder collisions

-

Axis overtravel alarms

-

Scrapped parts late in the cycle

Best practice:

Always use full digital twin simulation, including:

-

Exact machine kinematics

-

Tool, holder, and spindle models

-

Axis limits and safe zones

This is especially critical in aerospace and medical applications, where a single collision can invalidate an entire batch due to traceability requirements.

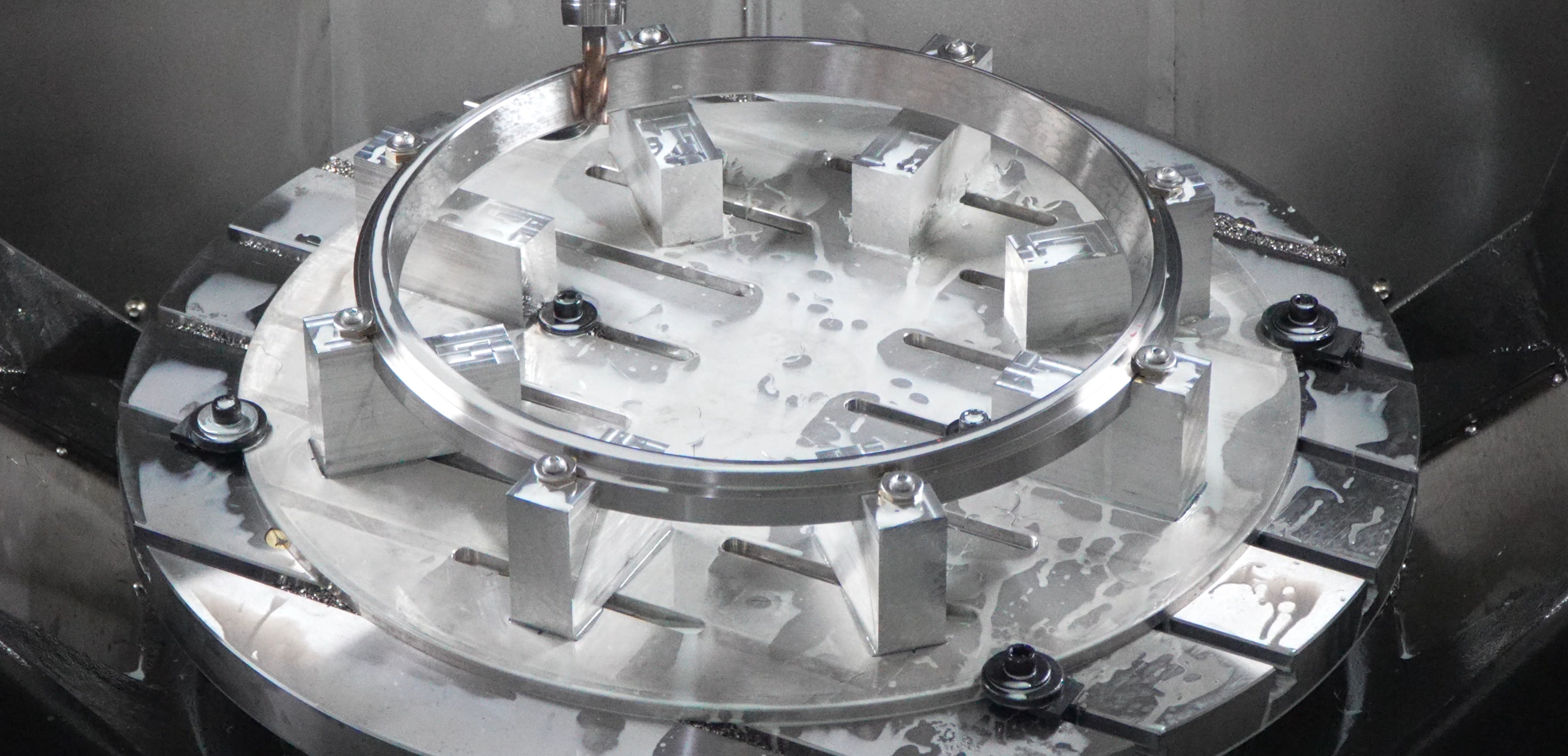

4. Neglecting Datum Strategy and Feature-Based GD&T Logic

Another costly mistake is programming without a clear datum and GD&T-driven strategy.

In 5-axis machining, it is tempting to “let the machine handle everything.” However, without a well-defined datum structure:

-

Critical features may drift relative to each other

-

Inspection results become inconsistent

-

Parts may pass CMM checks but fail functional assembly

This is particularly dangerous for:

-

Aerospace mounting interfaces

-

Medical implant mating surfaces

-

Sealing and load-bearing features

Best practice:

Align programming strategy with GD&T intent:

-

Maintain a single primary datum wherever possible

-

Sequence operations to protect critical features

-

Avoid unnecessary reorientation that introduces datum ambiguity

Precision machining is not just about hitting numbers—it is about maintaining functional relationships between features.

5. Underestimating Thermal Effects During Long 5-Axis Cycles

5-axis machining often involves:

-

Longer continuous cycles

-

High spindle loads

-

Multi-surface engagement

A common programming oversight is ignoring thermal growth of the machine, spindle, and workpiece.

Even small temperature changes can cause:

-

Micron-level drift over long cycles

-

Surface waviness on large parts

-

Inconsistent results between first-off and last-off parts

Key reality:

Steel expands ~10 μm per meter per °C. Without thermal compensation, tight ±2–5 μm tolerances become impossible to maintain.

Best practice:

-

Use machines with real-time thermal compensation

-

Program probing cycles for in-process verification

-

Balance cutting strategies to avoid localized heat buildup

Thermal stability must be considered at the programming stage, not corrected after inspection failures.

6. Overlooking Tool Length, Reach, and Rigidity Tradeoffs

5-axis machines enable access to deep features—but this often tempts programmers to use long-reach tools unnecessarily.

The result:

-

Reduced stiffness

-

Amplified vibration

-

Poor surface integrity

-

Higher scrap rates

In simultaneous 5-axis machining, many features can be accessed with shorter tools simply by reorienting the part, yet this advantage is frequently underused.

Best practice:

-

Prioritize shortest possible tool length

-

Use machine kinematics to gain access—not tool extension

-

Adjust tool orientation to maintain rigidity

This approach improves:

-

Surface finish consistency

-

Tool life

-

Dimensional stability across batches

7. Failing to Align Programming Strategy with Material Behavior

Different materials respond very differently to 5-axis machining—and ignoring this is a major programming error.

Examples:

-

Titanium: Sensitive to heat accumulation → requires controlled engagement and adaptive feeds

-

Inconel: Work-hardens rapidly → demands constant cutting conditions and vibration control

-

Medical alloys (Co-Cr, PEEK): Surface integrity is critical → excessive polishing or rework is unacceptable

Programming without accounting for material physics leads to:

-

Micro-cracks

-

Residual stress

-

Reduced fatigue life

Best practice:

Material behavior must influence:

-

Toolpath style

-

Feed and speed modulation

-

Entry and exit strategies

In critical industries, surface integrity is as important as dimensional accuracy.

8. Treating Post-Processing as a Final Step Instead of a Core Discipline

Post-processing errors are a hidden risk in 5-axis machining.

Generic or poorly tuned post-processors can:

-

Introduce axis reversal errors

-

Misinterpret rotary movements

-

Create unsafe transitions

These issues often remain invisible until:

-

A collision occurs

-

A tolerance violation appears

-

A machine alarm halts production

Best practice:

-

Use machine-specific, validated post-processors

-

Regularly verify output against simulation

-

Treat post-processing as part of the machining system—not an afterthought

Conclusion: 5-Axis Programming Is a System, Not a Shortcut

5-axis CNC machining delivers unmatched capability—but only when programming, machine dynamics, materials, and quality strategy work together as a system.

Avoiding these common mistakes enables manufacturers to:

-

Achieve true single-setup accuracy

-

Maintain sub-micron consistency

-

Reduce scrap and rework

-

Meet aerospace and medical regulatory demands with confidence

In critical component manufacturing, programming discipline is as important as machine capability.

FAQ

1. What are the most common mistakes in 5-axis CNC programming?

The most common mistakes include treating 5-axis machining like advanced 3-axis work, failing to optimize tool orientation, skipping full machine simulation, neglecting datum strategy, ignoring thermal effects, and using generic post-processors. These errors often lead to tolerance drift, poor surface finish, tool collisions, and inconsistent part quality—especially in aerospace and medical applications.

2. Why can’t 5-axis CNC machines be programmed like 3-axis machines?

Because 5-axis CNC machining relies on continuous coordination of linear and rotary axes, not fixed orientations. Programming with a 3-axis mindset introduces unnecessary re-setups, suboptimal tool angles, and cumulative datum errors—negating the primary advantages of 5-axis machining such as single-setup accuracy and surface integrity.

3. How does improper tool orientation affect 5-axis machining accuracy?

Incorrect lead and lag angles increase tool deflection, vibration, and uneven cutting forces. This directly degrades geometric accuracy and surface finish, particularly when machining titanium, Inconel, or thin-walled structures. Proper tool orientation allows shorter tools, better rigidity, and more stable micron-level results.

4. Is full machine simulation really necessary for 5-axis CNC programming?

Yes. Full kinematic simulation—including spindle, toolholder, rotary limits, and axis singularities—is essential. Many 5-axis failures occur due to incomplete simulation rather than machine capability. In regulated industries, a single collision can invalidate parts due to traceability and quality compliance requirements.