Selecting the right precision machining service is a critical decision that directly affects part quality, lead time, cost, and long-term reliability. Whether you are sourcing aerospace brackets, medical implants, or high-tolerance industrial components, not all machining suppliers are created equal. Understanding how precision machining services differ—and how to evaluate them systematically—can prevent costly delays, rework, and performance failures.

This guide breaks down the technical, operational, and commercial factors that matter most when choosing a precision machining service for your project.

CNC Machining vs. Precision Machining: Why the Distinction Matters

Many suppliers advertise CNC machining, but CNC machining alone does not guarantee precision machining. Precision machining refers to a higher manufacturing standard focused on micron-level tolerances, surface integrity, and repeatability across production runs.

A true precision machining service typically delivers:

-

Dimensional tolerances of ±1–5 µm

-

Controlled surface finishes (Ra ≤ 0.8 µm, often ≤ 0.4 µm)

-

Stable, repeatable results under thermal and mechanical variation

-

Full compliance with GD&T requirements

Understanding this distinction helps you filter out general job shops that may lack the equipment, process control, or quality systems required for high-risk components.

Step 1: Define Your Technical Requirements Clearly

Before evaluating any precision machining service, you must define your own project requirements with clarity.

Critical parameters to specify

-

Dimensional tolerance: Global vs. local tolerances, true position, flatness, concentricity

-

Surface tolerance: Ra, RMS, PV, and form deviation requirements

-

Material: Aluminum, titanium, Inconel, stainless steel, PEEK, cobalt-chrome

-

Part complexity: Undercuts, freeform surfaces, deep cavities, thin walls

-

Batch size: Prototype, small batch, or serial production

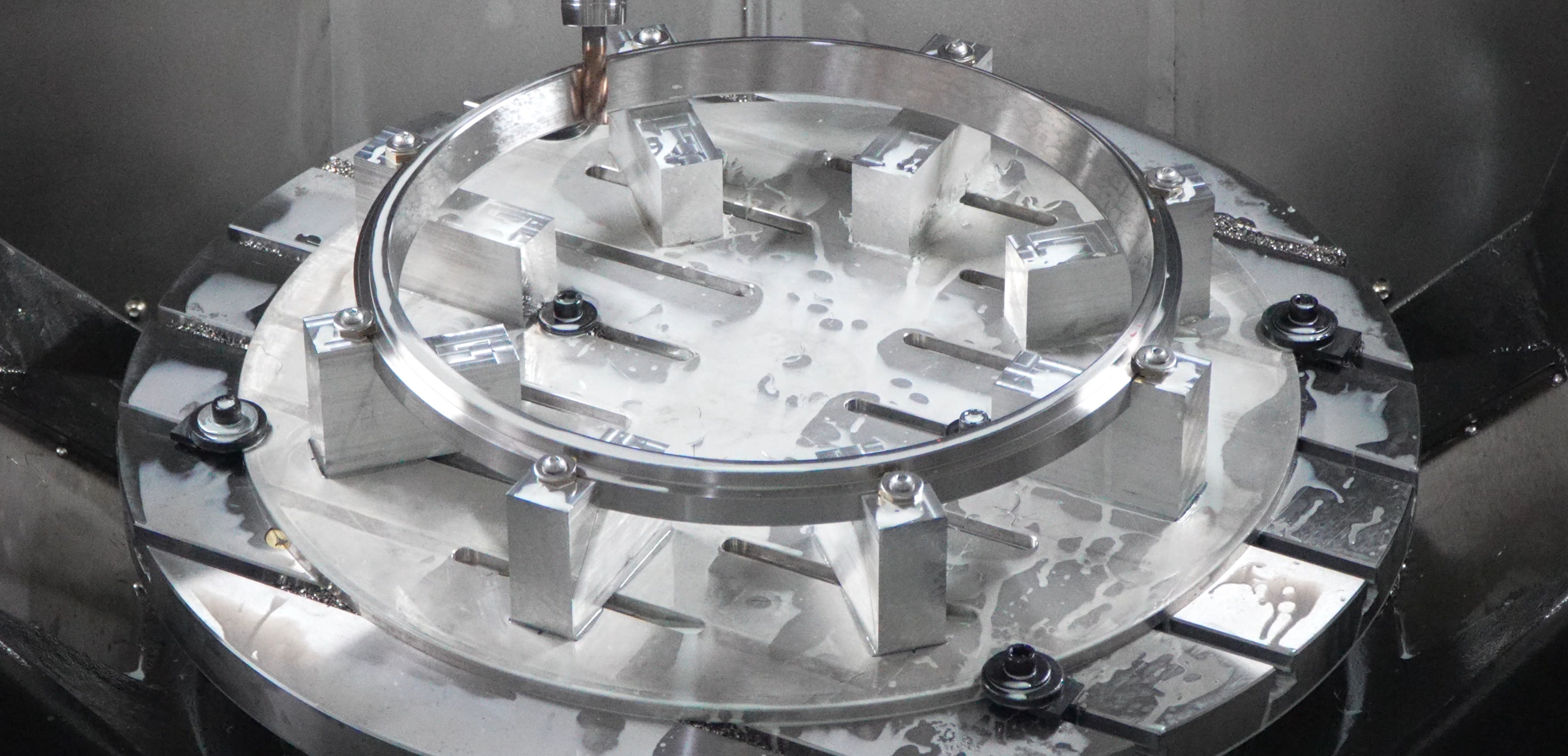

Projects requiring tight tolerances on complex geometries typically demand 5 axis CNC machining capability rather than 3-axis or indexed 3+2 solutions.

Step 2: Evaluate Machine Capability—Not Just Machine Count

A common mistake is judging a supplier by the number of CNC machines they own. What matters more is capability density.

Key questions to ask

-

Do they operate simultaneous 5 axis CNC machines, or only 3+2 indexed systems?

-

Are machines equipped with high-end spindles suitable for titanium and superalloys?

-

Is thermal compensation active and documented?

-

What is the verified positioning accuracy and repeatability?

Precision machining services capable of consistent micron-level accuracy typically rely on:

-

Single-setup 5 axis machining

-

Linear scales and closed-loop feedback

-

Rigid machine structures with low thermal drift

Without these, even advanced CAM programming cannot compensate for mechanical limitations.

Step 3: Process Control and Quality Systems

Precision machining is as much about process discipline as it is about hardware.

Indicators of a mature precision machining service

-

GD&T-driven fixturing and datum strategy

-

In-process probing and tool wear compensation

-

Statistical process control (Cp / Cpk tracking)

-

Full traceability of materials, tools, and programs

For regulated industries, verify certifications such as:

-

ISO 9001 (baseline)

-

AS9100 (aerospace)

-

ISO 13485 (medical devices)

A capable precision machining service should be able to explain how quality is achieved—not just show final inspection reports.

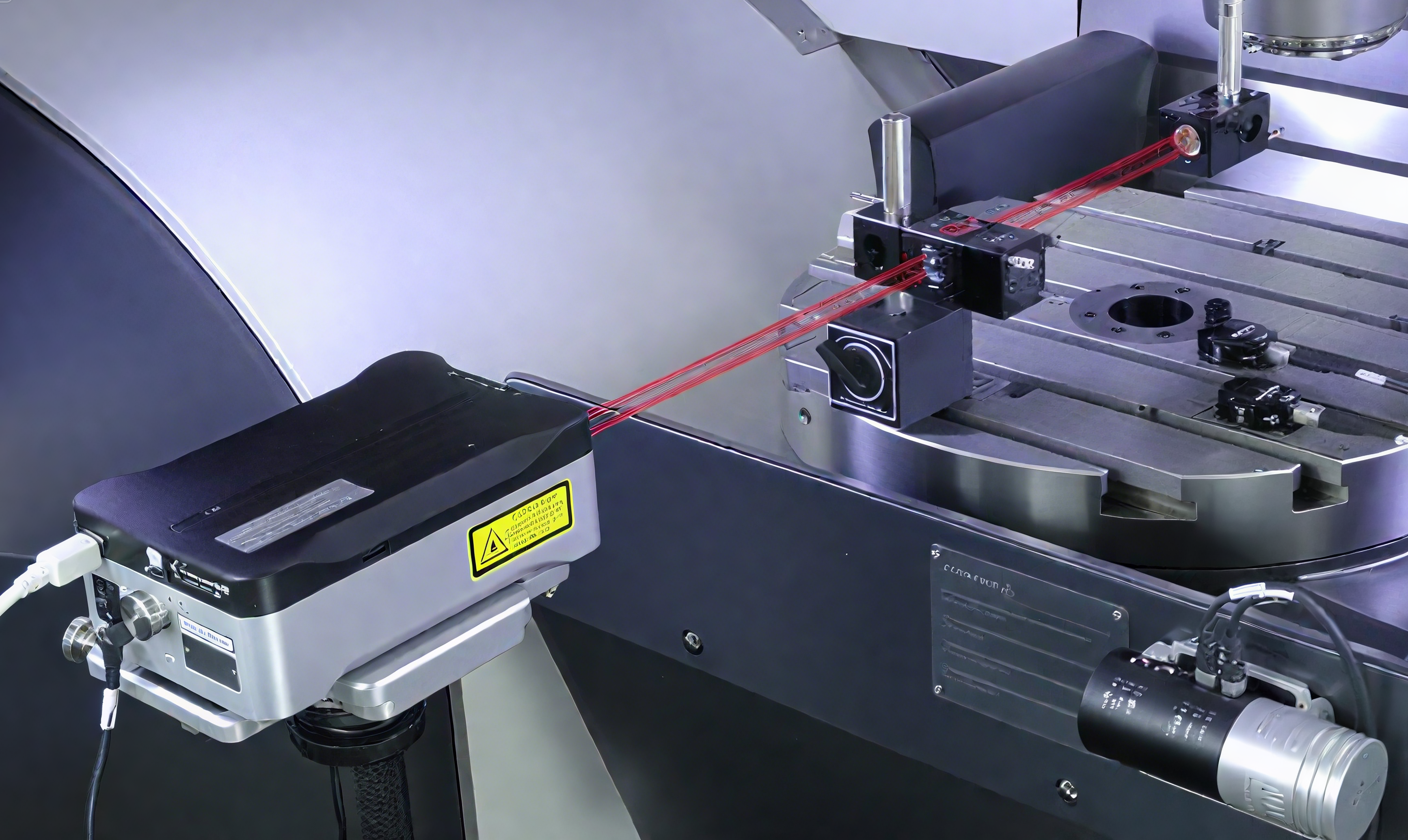

Step 4: Metrology Capability—How Precision Is Verified

Measurement capability is often the weakest link in supplier selection.

Essential metrology tools

-

Coordinate Measuring Machines (CMM) with sub-micron uncertainty

-

On-machine probing for in-process verification

-

Surface roughness and form measurement systems

-

Optical or laser scanning for complex geometries

A strong precision machining service uses a layered inspection strategy:

-

In-process control to prevent defects

-

Final CMM validation for certification

-

Archived inspection data for repeatability

Without proper metrology, claimed tolerances cannot be trusted.

Step 5: Material Expertise and Machining Strategy

Different materials behave very differently under machining forces and thermal loads.

What to look for

-

Proven experience machining titanium and Inconel without surface damage

-

Adaptive toolpaths to manage work hardening

-

Vibration control for thin-wall or low-stiffness parts

-

Material-specific coolant and chip evacuation strategies

Precision machining services that lack material expertise often achieve nominal dimensions—but compromise fatigue life, surface integrity, or long-term stability.

Step 6: Cost Transparency and Long-Term Value

The lowest quote is rarely the lowest total cost.

When evaluating pricing, consider:

-

Scrap and rework risk

-

Lead time reliability

-

Engineering support during DFM

-

Scalability from prototype to production

A higher-quality precision machining service often reduces total cost by eliminating secondary operations, rework, and inspection bottlenecks—especially when using single-setup 5 axis CNC machining.

Industry-Specific Considerations

Aerospace

-

Flight-critical tolerance control

-

Fatigue performance and traceability

-

Compliance with AS9100 and customer audits

Medical

-

Biocompatible surface finishes

-

Full documentation under ISO 13485

-

Repeatability for patient-specific parts

High-End Industrial Applications

-

Long-term dimensional stability

-

Tight assembly fits

-

Consistent surface quality across batches

Choosing a precision machining service experienced in your target industry significantly reduces qualification time and risk.

FAQ

What is the difference between CNC machining and precision machining?

CNC machining refers to computer-controlled manufacturing in general, while precision machining focuses on achieving micron-level tolerances, controlled surface finishes, and repeatable accuracy using advanced equipment and process control.

When should I choose a 5 axis precision machining service?

When your parts involve complex geometries, tight tolerances, or multiple features that would otherwise require re-fixturing, simultaneous 5 axis CNC machining is the preferred solution.

How can I verify a supplier’s precision capability?

Request documented machine accuracy, inspection reports, Cp/Cpk data, and examples of similar completed projects. Metrology capability is as important as machining equipment.

Is precision machining always more expensive?

While hourly rates may be higher, precision machining often lowers total cost by reducing scrap, rework, setup time, and downstream quality issues.