The future of CNC machining is no longer defined by standalone machine performance. As manufacturing moves toward higher precision, lower batch sizes, and stricter regulatory oversight, 5 axis CNC machining is increasingly integrated with automation and AI to form intelligent, self-optimizing production systems.

This evolution is not optional. In aerospace, medical, and other critical industries, the combination of 5 axis CNC machines, automation, and AI-driven decision-making is becoming the baseline for competitiveness, quality assurance, and long-term scalability.

From Isolated Machines to Intelligent Manufacturing Systems

Traditional CNC machining treated each machine as an independent unit. Operators loaded parts, programs were manually adjusted, and quality feedback arrived only after inspection. This model struggles under today’s requirements for traceability, repeatability, and micron-level consistency.

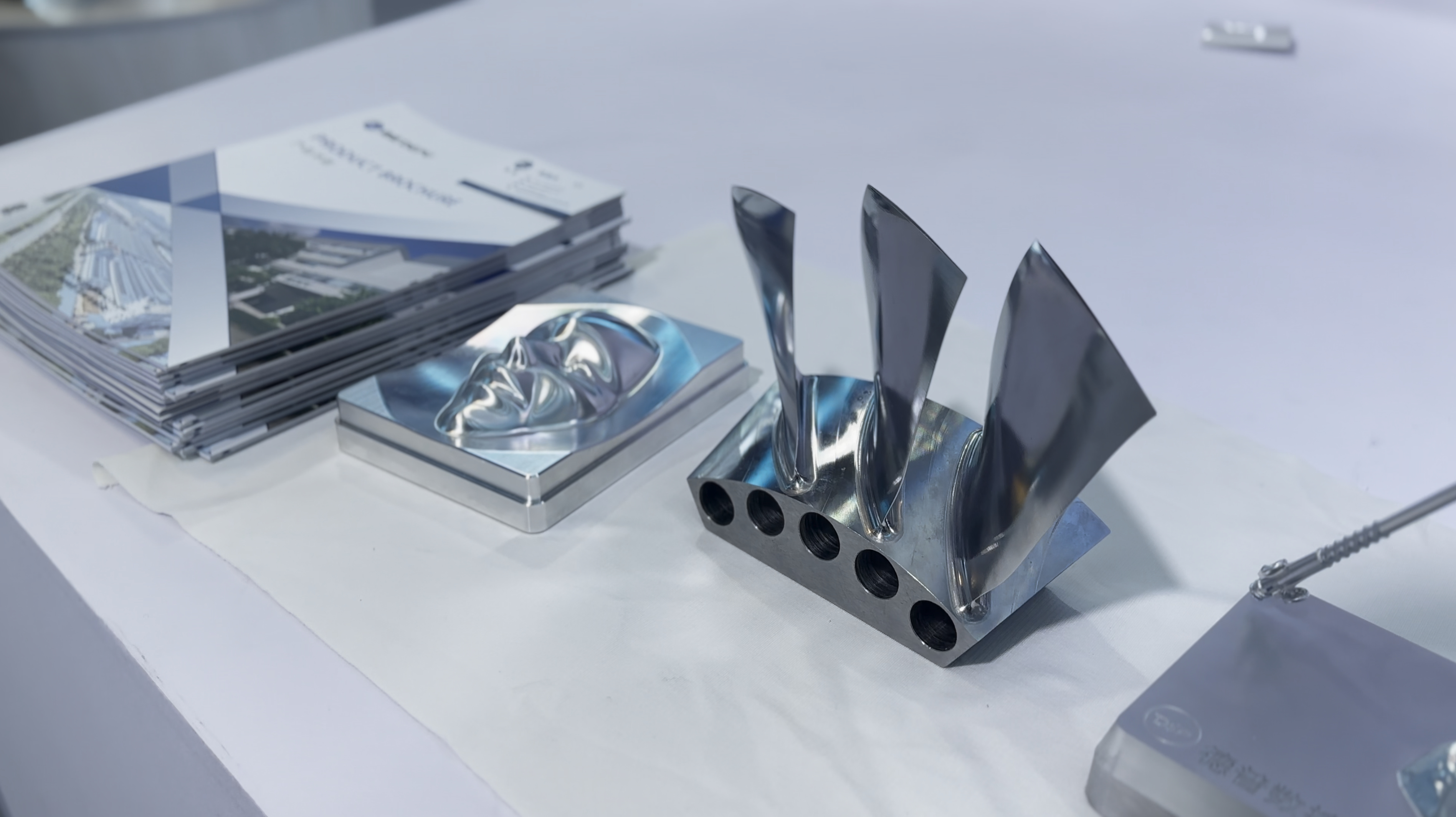

Modern 5 axis CNC machining changes this paradigm. By nature, 5 axis CNC machines generate richer datasets: tool orientation vectors, rotary axis loads, thermal behavior, and real-time kinematic feedback. When connected to automation and AI platforms, this data becomes actionable intelligence rather than unused machine logs.

As a result, automation and AI transform 5 axis CNC machines from cutting tools into adaptive manufacturing nodes.

Why 5 Axis CNC Machines Are the Foundation of CNC Automation

Not all CNC platforms integrate with automation equally. 5 axis CNC machines are uniquely suited for automation due to three structural advantages.

Single-Setup Machining Enables Robotic Consistency

Automation thrives on repeatability. Multi-setup 3-axis workflows introduce variability at every re-clamping step, making robotic loading and unloading unreliable.

In contrast, 5 axis CNC machining enables complete part machining in a single setup. This allows automation systems to:

-

Load raw material

-

Execute full machining cycles

-

Unload finished parts

without manual intervention or re-alignment.

This single-setup logic is essential for lights-out manufacturing and is one reason 5 axis CNC machines dominate automated aerospace and medical production lines.

Reduced Fixturing Complexity Improves Automation Reliability

Automation systems struggle with complex, custom fixturing. Because 5 axis CNC machining provides full access to all part surfaces, fixturing can be simplified and standardized.

Simpler fixtures mean:

-

Faster robotic changeovers

-

Lower risk of misalignment

-

Higher automation uptime

This mechanical simplicity is a critical enabler for scalable automation and AI integration.

AI-Driven Toolpath Optimization in 5 Axis CNC Machining

One of the most impactful applications of automation and AI is in toolpath optimization for 5 axis CNC machining.

Adaptive Feed and Speed Control

AI systems analyze spindle load, vibration signals, and tool wear patterns in real time. Instead of relying on static CAM parameters, AI dynamically adjusts:

-

Feed rates

-

Tool orientation

-

Engagement angles

In 5 axis CNC machining, where cutting conditions constantly change due to simultaneous rotary motion, this adaptive control significantly improves surface integrity and tool life.

Predictive Collision Avoidance

AI-enhanced simulation models continuously compare planned toolpaths with real machine behavior. This reduces collision risk caused by:

-

Axis synchronization errors

-

Thermal drift

-

Unexpected material deformation

For complex geometries, AI-supported 5 axis CNC machines can detect unsafe motion before it becomes a physical event.

Automation, AI, and Closed-Loop Quality Control

Quality control is no longer a downstream process. In advanced CNC environments, automation and AI close the loop between machining and inspection.

In-Process Measurement and AI Feedback

Modern 5 axis CNC machines integrate probing systems that measure critical features during machining. AI algorithms evaluate this data instantly and determine whether:

-

Tool offsets need correction

-

Thermal compensation is required

-

Subsequent operations should be adjusted

This closed-loop approach reduces scrap and ensures dimensional consistency across long production runs.

Learning from Historical Data

AI systems continuously learn from past cycles. Over time, automation and AI identify patterns such as:

-

Which toolpaths generate the most stable surfaces

-

How materials respond under different cutting strategies

-

Where dimensional drift typically begins

These insights directly improve future 5 axis CNC machining programs without human trial-and-error.

Digital Twins and Smart Factories Built Around 5 Axis CNC Machines

The concept of the digital twin is central to the future of CNC manufacturing.

A digital twin is a virtual replica of a physical 5 axis CNC machine, continuously updated with live data. This allows manufacturers to:

-

Simulate process changes before implementation

-

Predict maintenance needs

-

Optimize production schedules

In smart factories, automation and AI orchestrate multiple 5 axis CNC machines as a unified system rather than isolated assets.

This system-level optimization is impossible without the rich kinematic and process data generated by 5 axis CNC machining.

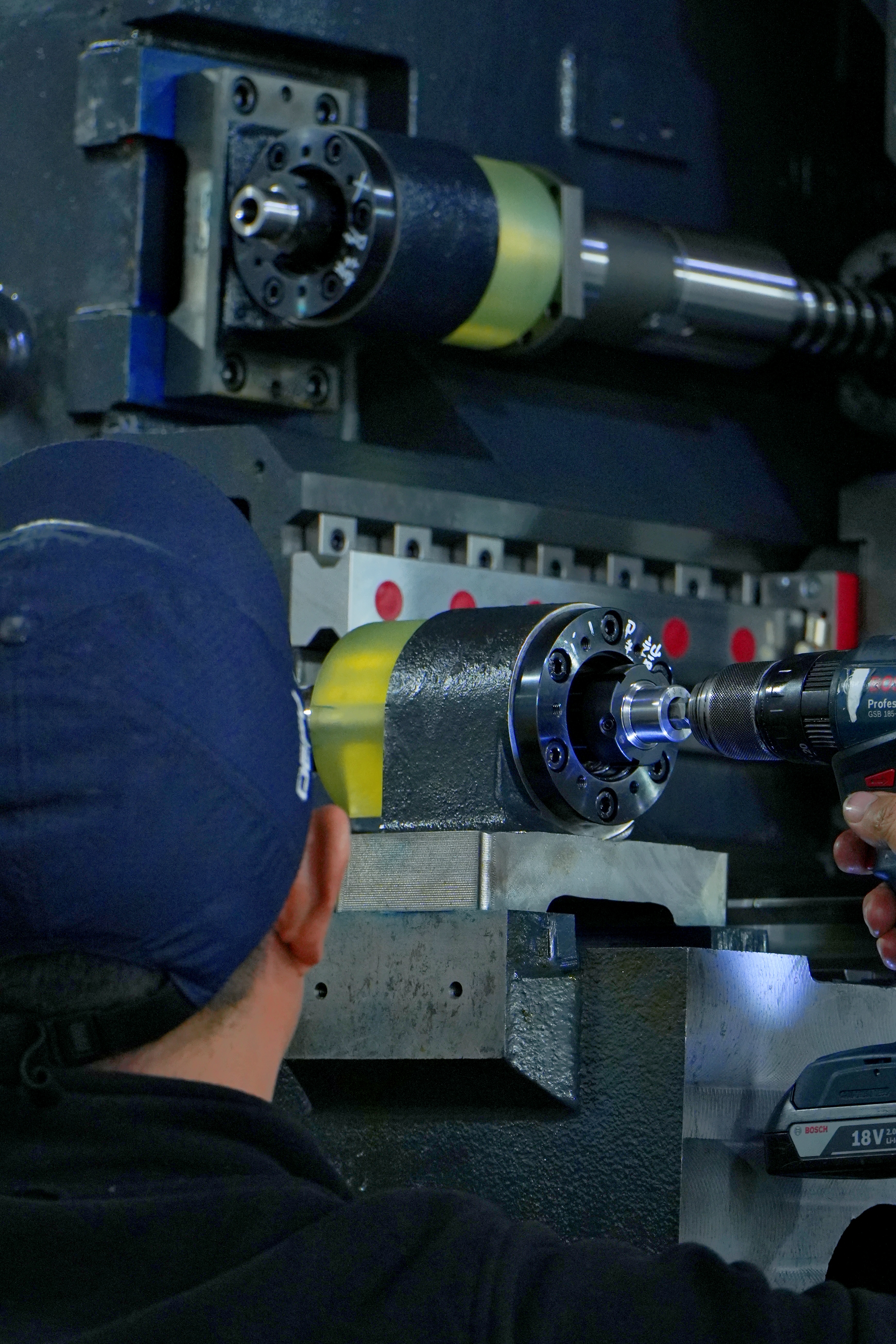

Workforce Evolution: From Operators to System Engineers

Automation does not eliminate human expertise—it elevates it.

As automation and AI handle repetitive tasks, skilled personnel shift toward:

-

Process optimization

-

Data analysis

-

Quality strategy development

Engineers overseeing 5 axis CNC machines increasingly focus on system-level decisions rather than manual adjustments. This transition improves consistency while preserving critical engineering judgment.

Challenges in Integrating Automation and AI with 5 Axis CNC Machining

Despite its advantages, integration is not without challenges.

Common barriers include:

-

Poor data quality from legacy machines

-

Incompatible post-processors

-

Lack of standardized communication protocols

Successful adoption of automation and AI requires treating 5 axis CNC machining as part of a complete manufacturing ecosystem, not a standalone upgrade.

The Strategic Future of CNC Manufacturing

The future of CNC is clear: 5 axis CNC machines, automation, and AI will define the next generation of precision manufacturing.

Manufacturers who adopt this integrated approach gain:

-

Higher throughput with fewer errors

-

Predictable micron-level quality

-

Scalable production for high-mix, low-volume demand

Those who delay will find it increasingly difficult to compete in industries where precision, traceability, and reliability are non-negotiable.

In this future, 5 axis CNC machining is not simply a capability—it is the structural backbone that enables intelligent, automated, and AI-driven manufacturing.

FAQ

1. Why are 5 axis CNC machines better suited for automation than 3-axis machines?

5 axis CNC machines enable complete part machining in a single setup, reducing manual intervention and fixturing complexity. This consistency makes robotic loading, automated workflows, and AI-driven process control far more reliable than with multi-setup 3-axis machining.

2. How does AI improve accuracy in 5 axis CNC machining?

AI analyzes real-time data such as spindle load, vibration, and thermal behavior during 5 axis CNC machining. Based on this data, AI dynamically adjusts feed rates, tool orientation, and offsets to maintain stable cutting conditions and micron-level accuracy.

3. Can existing 5 axis CNC machines be upgraded with automation and AI?

Many modern 5 axis CNC machines can be retrofitted with automation and AI through software upgrades, sensors, and connectivity modules. However, successful integration depends on machine rigidity, control system openness, and data quality.

4. What industries benefit most from 5 axis CNC automation and AI integration?

Industries requiring complex geometry and strict quality control—such as aerospace, medical devices, and energy—gain the most from automation and AI combined with 5 axis CNC machining, as it delivers higher consistency, traceability, and production efficiency.