Why This Distinction Matters in High-End Manufacturing

In global manufacturing discussions, CNC machining and precision machining are often used interchangeably. In reality, they are not the same. Understanding the difference between CNC vs precision machining is critical for aerospace, medical, semiconductor, and high-end industrial buyers—where micron-level errors translate directly into performance risk, regulatory failure, or costly scrap.

At its core, CNC machining describes how parts are made, while precision machining defines how accurately they must be made. The overlap is significant, but the distinction determines machine selection, process control, inspection strategy, and total cost of ownership.

What Is CNC Machining?

CNC machining (Computer Numerical Control machining) refers to any subtractive manufacturing process where machine motion is controlled by a programmed digital system. CNC machining focuses on automation, repeatability, and productivity.

Key Characteristics of CNC Machining

-

Computer-controlled motion of axes (typically 3, 4, or 5 axes)

-

Programmed toolpaths generated via CAM software

-

Suitable for milling, turning, drilling, and tapping

-

Emphasis on throughput, consistency, and scalability

CNC machining is widely used in general industrial production, automotive components, fixtures, housings, and medium-tolerance parts. Typical CNC machining tolerances range from ±0.01 mm to ±0.05 mm, depending on machine quality and setup.

In short, CNC machining defines the control method, not the performance ceiling.

What Is Precision Machining?

Precision machining is a manufacturing discipline focused on achieving extremely tight tolerances, superior surface integrity, and long-term dimensional stability—often at the micron or sub-micron level.

Precision machining may use CNC machines, but not all CNC machining qualifies as precision machining.

Key Characteristics of Precision Machining

-

Tolerances commonly between ±1–5 microns

-

Controlled thermal environment and machine compensation

-

High-end spindles, linear scales, and feedback systems

-

Advanced GD&T-driven process planning

-

Comprehensive in-process and post-process metrology

Precision machining is essential for aerospace engine components, medical implants, optical parts, semiconductor tooling, and high-performance mold cores.

CNC vs. Precision Machining: Core Differences Explained

| Dimension | CNC Machining | Precision Machining |

|---|---|---|

| Primary Focus | Automation & repeatability | Accuracy & stability |

| Typical Tolerance | ±0.01–0.05 mm | ±1–5 µm |

| Machine Requirement | Standard CNC | High-end CNC + compensation |

| Thermal Control | Limited | Actively managed |

| Metrology | End-of-process | In-process + certification |

| Application Risk | Moderate | Mission-critical |

This comparison highlights why CNC vs precision machining is not a binary choice—but a hierarchy of capability.

Where 5-Axis CNC Bridges CNC and Precision Machining

Modern 5-axis CNC machining is where CNC machining and precision machining increasingly converge.

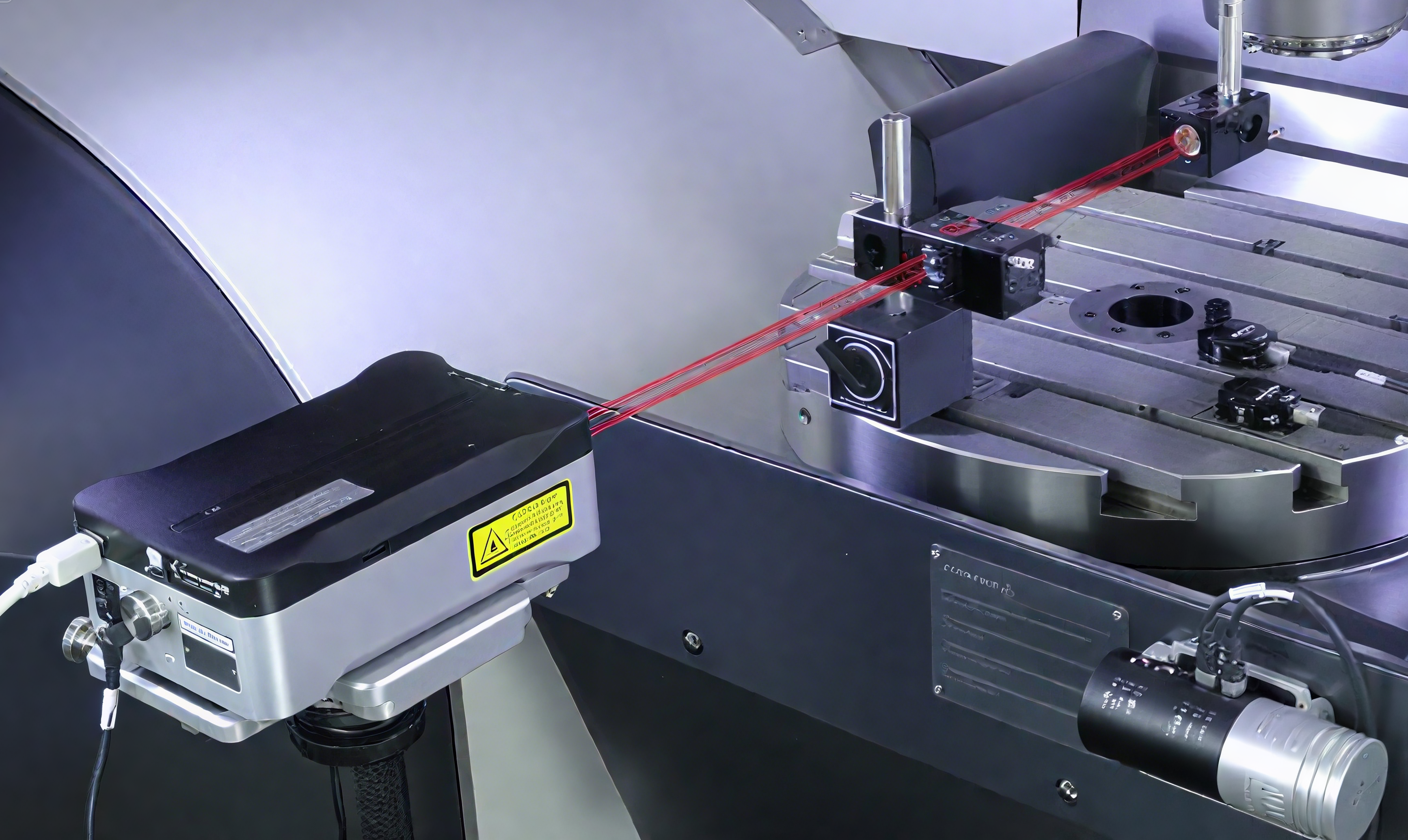

Simultaneous 5-axis systems maintain optimal tool orientation, minimize re-clamping, and reduce cumulative datum error. When combined with:

-

Linear scale feedback

-

Real-time thermal compensation

-

High-rigidity machine structures

-

Adaptive toolpath control

5-axis CNC machines become true precision machining platforms capable of sub-5 micron positional accuracy and Ra < 0.4 µm surface finishes.

This is why advanced aerospace and medical manufacturers evaluate CNC vs precision machining through the lens of machine architecture, not axis count alone.

Accuracy Is More Than Tolerance: Geometry, Surface, and Stability

Precision machining extends beyond dimensional tolerance into three interdependent domains:

1. Geometric Integrity

Form accuracy, positional accuracy, and profile tolerances must remain stable across the entire part—not just at inspection points.

2. Surface Integrity

Precision machining controls surface roughness, peak-to-valley variation, and subsurface deformation. For implants and turbine components, Ra < 0.4 µm is often a functional requirement, not a cosmetic one.

3. Thermal and Mechanical Stability

Without thermal compensation, steel structures can expand 10–12 µm per meter per °C, immediately violating precision machining requirements even if CNC programs are correct.

Cost Perspective: CNC vs Precision Machining

From a cost standpoint, CNC machining prioritizes cost per part, while precision machining prioritizes cost of failure.

Precision machining involves:

-

Higher machine investment

-

Longer setup and validation cycles

-

Advanced inspection equipment

However, in aerospace and medical manufacturing, a single nonconforming part can outweigh years of cost savings from lower-end CNC machining.

This is why CNC vs precision machining decisions are increasingly driven by total risk-adjusted cost, not hourly machine rates.

Industry Applications That Demand Precision Machining

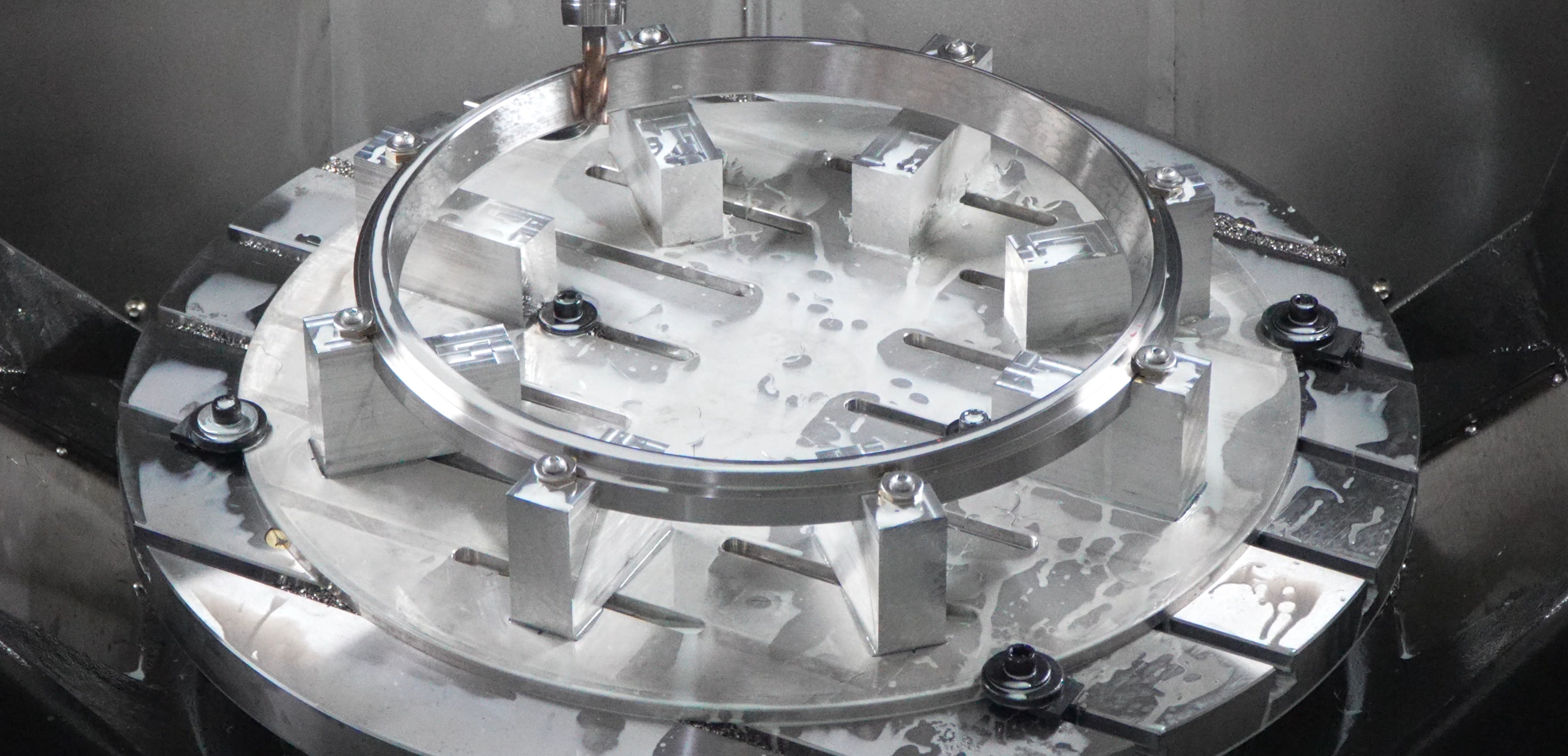

Aerospace

-

Turbine blades, blisks, housings

-

Tight rotor-stator clearances

-

Fatigue-critical geometry

Medical

-

Orthopedic and spinal implants

-

Biocompatible surface requirements

-

FDA 21 CFR Part 820 compliance

Semiconductor & Optics

-

Ultra-flat surfaces

-

Sub-micron form accuracy

-

Thermal distortion control

In all these sectors, CNC machining is necessary—but precision machining is non-negotiable.

FAQ: CNC vs. Precision Machining

What is the main difference between CNC machining and precision machining?

CNC machining refers to computer-controlled manufacturing, while precision machining focuses on achieving extremely tight tolerances, surface quality, and stability. Precision machining often uses CNC equipment, but with much higher control standards.

Is all precision machining done on CNC machines?

Most modern precision machining uses CNC machines, especially high-end 5-axis systems. However, not all CNC machining meets precision machining requirements.

When should I choose precision machining over standard CNC machining?

Precision machining is required when tolerances fall below ±5 microns, when surface integrity affects performance, or when failure carries high safety or regulatory risk.

Does 5-axis CNC automatically mean precision machining?

No. 5-axis capability improves access and accuracy, but precision machining depends on machine quality, thermal control, feedback systems, and process discipline.