As manufacturing moves toward lighter structures, higher operating temperatures, and tighter functional tolerances, material selection has become inseparable from machining capability. Many advanced materials simply cannot reach their designed performance without precision machining. Tight dimensional control, stable surface integrity, and repeatable accuracy at the micron level are no longer optional—they are fundamental requirements.

This article explores the advanced materials that benefit most from precision machining, explains why conventional machining often fails with these materials, and outlines the machining strategies required to unlock their full performance.

Why Advanced Materials Demand Precision Machining

Advanced materials are engineered to deliver exceptional strength-to-weight ratios, thermal resistance, biocompatibility, or dimensional stability. However, these same properties often make them difficult to machine.

Key challenges include:

-

High cutting forces and rapid tool wear

-

Poor thermal conductivity leading to heat concentration

-

Work hardening and residual stress

-

Sensitivity to vibration and micro-deflection

Precision machining addresses these issues through rigid machine structures, single-setup workflows, controlled tool engagement, and micron-level feedback systems. Without precision machining, advanced materials may meet nominal dimensions but fail in fatigue life, surface integrity, or long-term stability.

Titanium Alloys: Strength-to-Weight Excellence Requires Control

Titanium alloys such as Ti-6Al-4V are widely used in aerospace, medical, and high-performance industrial applications due to their exceptional strength-to-weight ratio and corrosion resistance.

Why titanium benefits from precision machining

-

Low thermal conductivity traps heat at the cutting edge

-

High chemical reactivity accelerates tool wear

-

Elastic recovery causes dimensional spring-back

Precision machining—especially single-setup 5 axis CNC machining—maintains optimal tool orientation, minimizes heat buildup, and controls deflection. This enables tolerances below ±5 µm and surface finishes under 0.4 µm Ra, critical for aerospace brackets and orthopedic implants.

Without precision machining, titanium components often suffer from micro-cracking, poor fatigue performance, and inconsistent geometry across batches.

Nickel-Based Superalloys: Inconel and Heat-Resistant Alloys

Nickel-based superalloys such as Inconel 718 and Hastelloy are designed for extreme environments, including jet engines, turbines, and energy systems.

Machining challenges

-

Severe work hardening

-

Cutting forces exceeding 40 kN

-

Rapid tool degradation

Precision machining enables adaptive toolpaths, real-time tool wear compensation, and vibration damping—essential for maintaining geometric accuracy. In precision machining environments, Inconel parts consistently achieve surface roughness below 0.8 µm Ra and positional tolerances under ±5 µm.

This level of control directly impacts fatigue life and thermal reliability in flight-critical and energy-sector components.

Cobalt-Chromium Alloys: Precision for Medical Performance

Cobalt-chromium alloys are commonly used in orthopedic and dental implants due to their strength, wear resistance, and biocompatibility.

Why precision machining is essential

-

Extremely high hardness

-

Sensitivity to surface defects

-

Strict regulatory requirements

Precision machining ensures smooth, defect-free surfaces that reduce bacterial adhesion and improve osseointegration. Achieving Ra values below 0.4 µm without secondary polishing preserves material integrity and simplifies regulatory validation under ISO 13485 and FDA 21 CFR Part 820.

Engineering Plastics: PEEK, PTFE, and UHMW

High-performance polymers are increasingly replacing metals in medical, semiconductor, and aerospace applications.

Precision machining advantages

-

Controls thermal expansion and creep

-

Prevents burr formation and surface tearing

-

Maintains tight tolerances in thin-wall features

Materials like PEEK benefit from precision machining strategies that manage heat input and vibration. Tolerances of ±10 µm and surface finishes below 0.8 µm Ra are routinely achievable when machining conditions are tightly controlled.

Ceramics and Technical Glasses: Fragile Materials Demand Absolute Stability

Advanced ceramics and materials such as alumina, zirconia, and fused silica offer exceptional thermal and chemical stability—but are extremely brittle.

Why precision machining matters

-

Minimal tolerance for mechanical shock

-

High risk of micro-fractures

-

Sensitivity to tool engagement angles

Precision machining uses low-vibration systems, diamond tooling, and controlled feed strategies to achieve form accuracy below ±5 µm and surface finishes approaching optical quality (<0.05 µm Ra in finishing processes).

Invar and Low-Expansion Alloys: Dimensional Stability Above All

Invar alloys are used in aerospace tooling, metrology frames, and optical systems where dimensional stability is critical.

Although Invar has extremely low thermal expansion, it is highly sensitive to vibration and cutting-induced stress. Precision machining with rigid fixturing and low-frequency vibration control is required to maintain flatness and positional accuracy over large parts.

Comparison Table: Advanced Materials and Precision Machining Benefits

| Material | Key Challenge | Precision Machining Benefit |

|---|---|---|

| Titanium | Heat concentration | Controlled tool engagement, low distortion |

| Inconel | Work hardening | Adaptive toolpaths, stable geometry |

| Cobalt-Chrome | Surface sensitivity | Sub-0.4 µm Ra finishes |

| PEEK | Thermal creep | Dimensional stability |

| Ceramics | Brittleness | Crack-free surfaces |

| Invar | Vibration sensitivity | Long-term dimensional accuracy |

How to Match Material Choice with Precision Machining Capability

Choosing advanced materials without evaluating machining capability leads to cost overruns and performance risk. A qualified precision machining service should demonstrate:

-

Proven experience with target materials

-

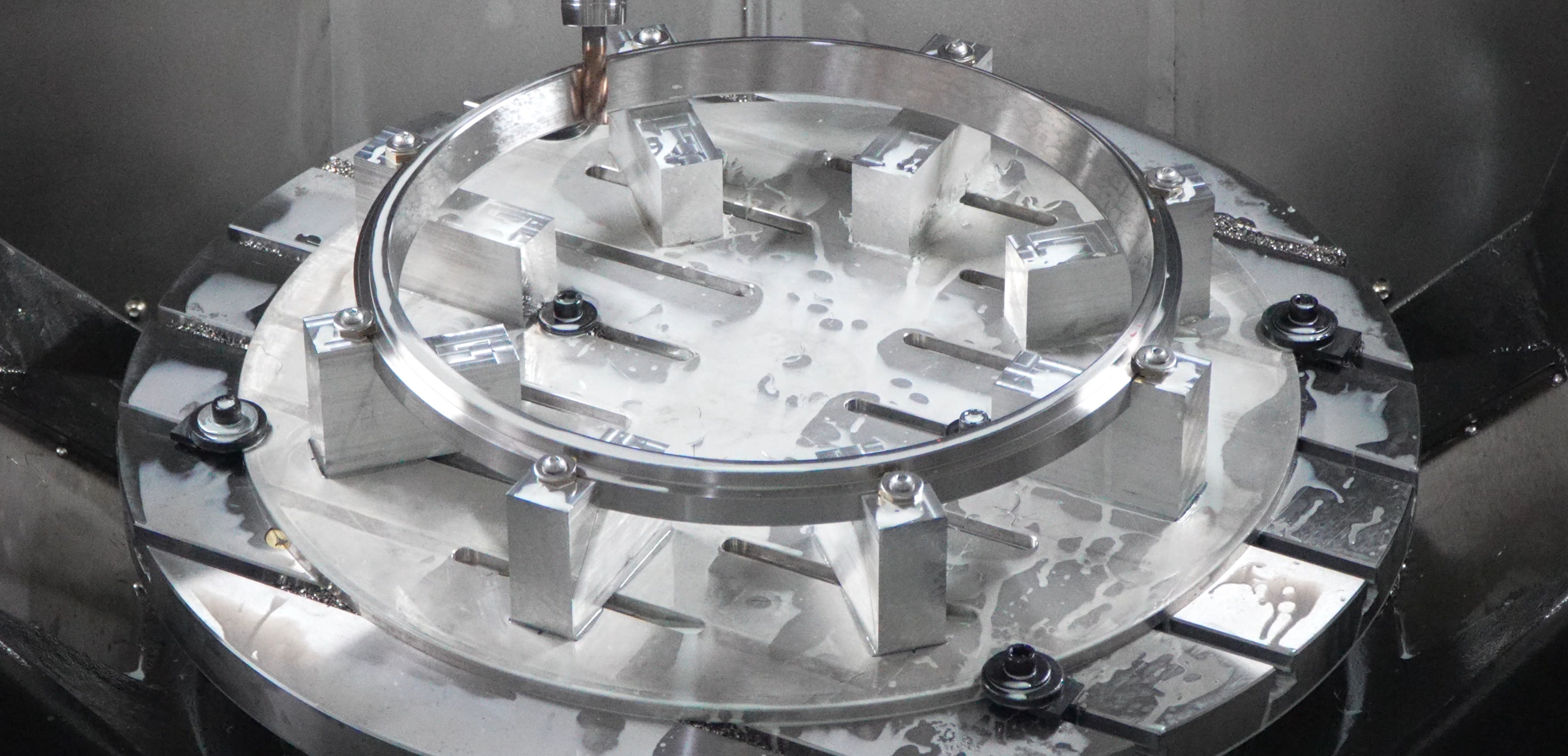

5 axis CNC machining capability for complex geometries

-

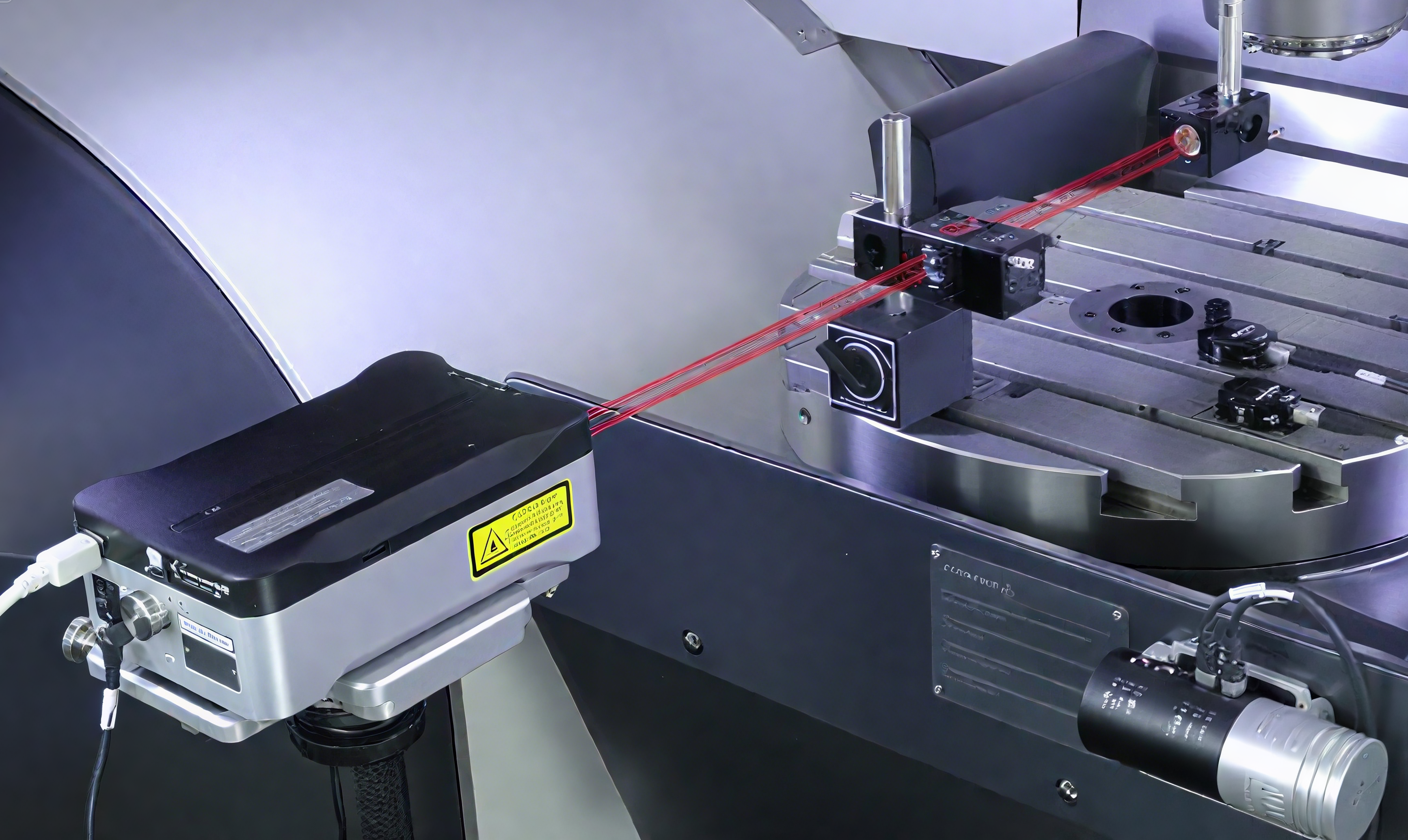

In-process measurement and thermal compensation

-

Documented quality control and traceability

Precision machining is not just about making parts smaller—it is about ensuring advanced materials perform as designed throughout their service life.

FAQ

What materials benefit most from precision machining?

Titanium alloys, nickel-based superalloys, cobalt-chromium, advanced polymers, ceramics, and low-expansion alloys like Invar benefit most due to their demanding mechanical and thermal properties.

Why is precision machining critical for titanium and Inconel?

These materials generate high cutting forces and retain heat, requiring precise tool control and thermal stability to prevent distortion and premature failure.

Can precision machining reduce secondary finishing operations?

Yes. Precision machining often achieves final surface and dimensional requirements directly, eliminating polishing, grinding, or rework steps.

Is 5 axis CNC machining necessary for advanced materials?

For complex geometries and tight tolerances, simultaneous 5 axis CNC machining significantly improves accuracy, surface quality, and consistency.