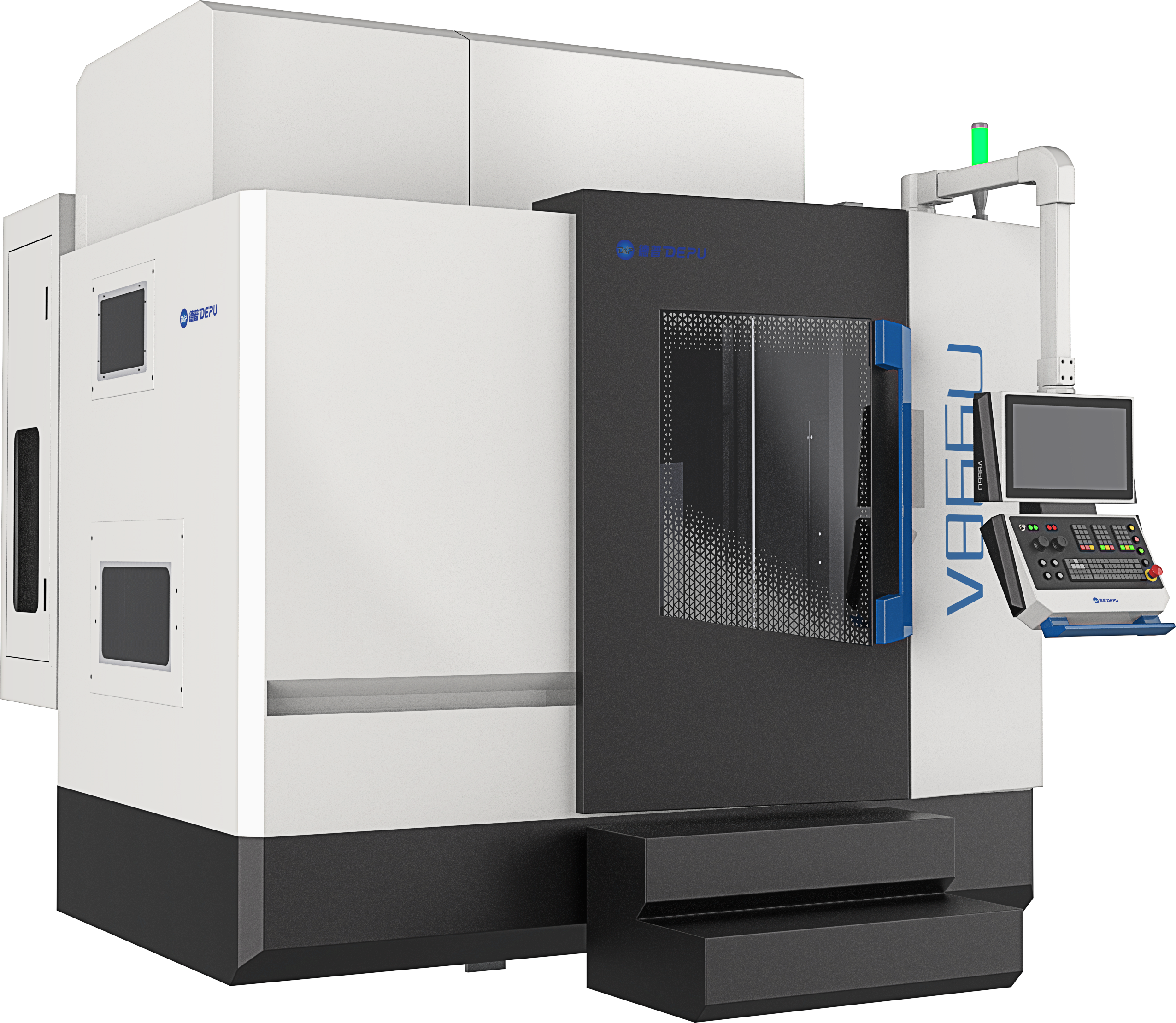

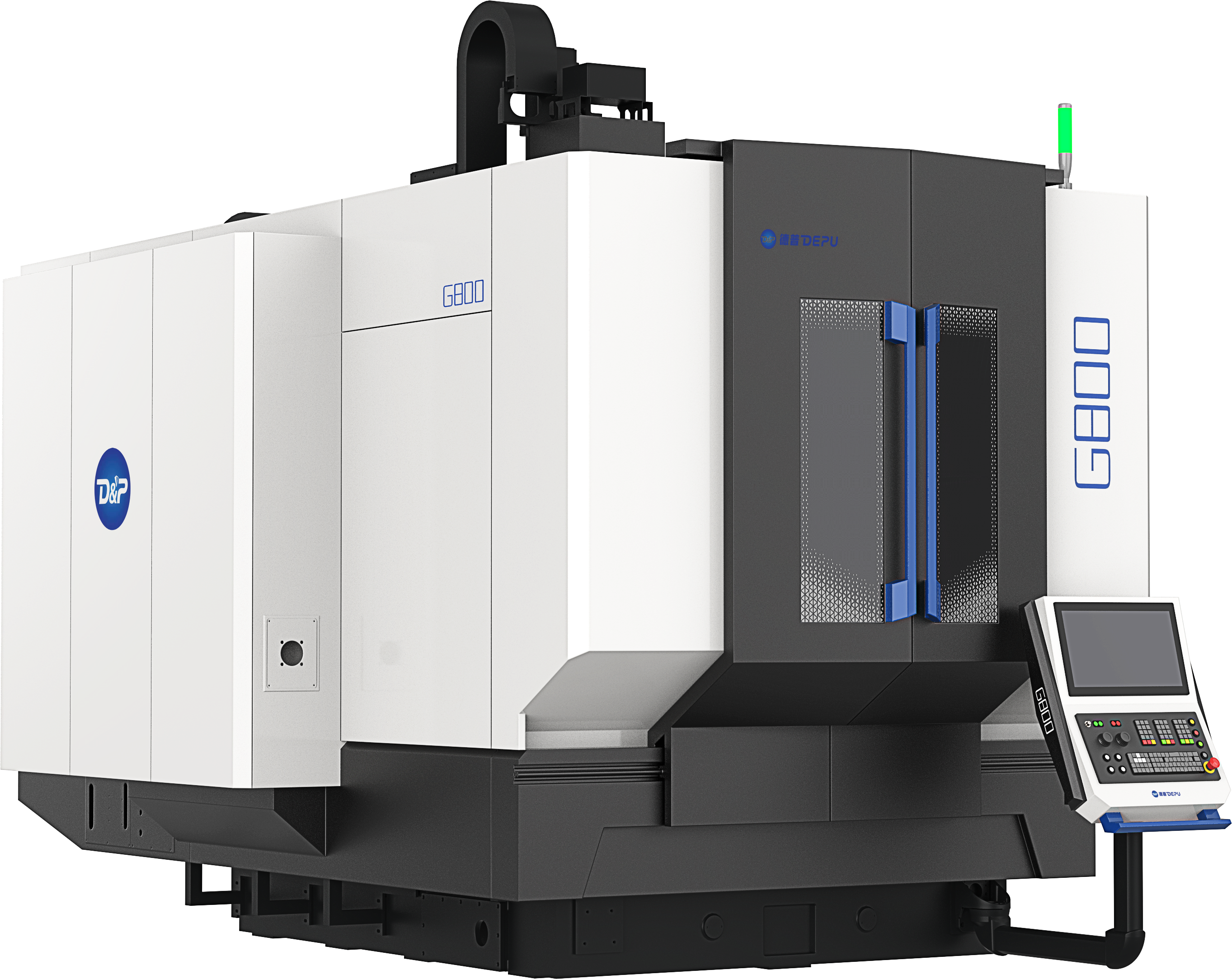

Precision Vertical Milling Machines | CNC & Manual Models for Industrial & Toolroom Use

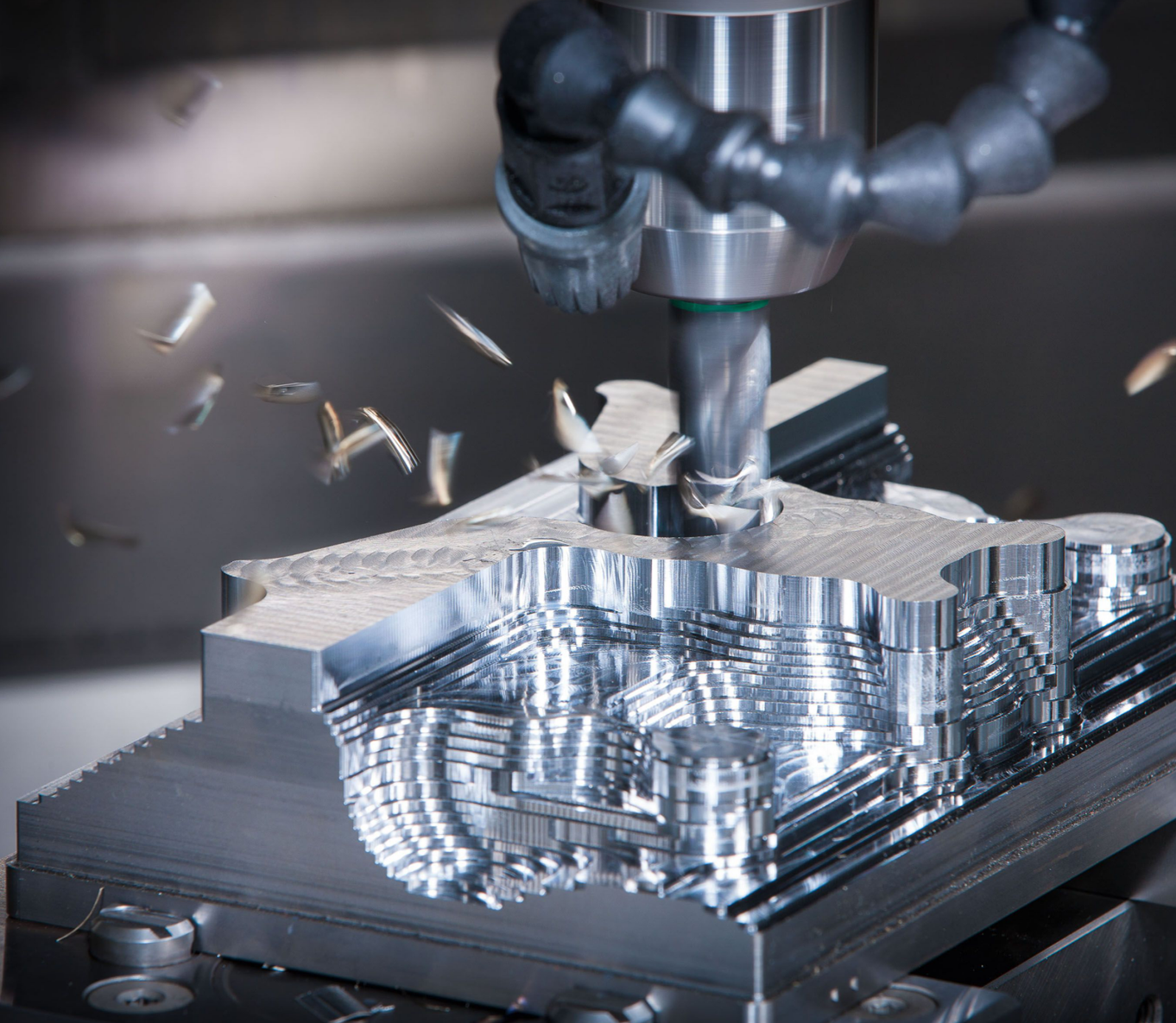

Welcome to your next level of machining excellence. Our vertical milling machines are designed to be the backbone of the shop, with outstanding rigidity, precision, and flexibility. Our machines utilise a vertically oriented spindle that holds and rotates the cutting tool against the stationary workpiece and can handle anything from simple drilling to complex contouring, with precision and accuracy that is second to none.

It makes no difference if you are toolmaker, production engineer, or skilled hobbyist, our selection of manual and CNC vertical mills will give you that power and control to turn your raw material into high quality precision components.

Copyright © DEPU CNC (Shenzhen) Co., Ltd. - Privacy policy