Độ chính xác vượt trội và dung sai chặt chẽ hơn với máy cnc năm trục

Tại sao gia công 3 trục không đáp ứng được yêu cầu độ chính xác cao

Các máy CNC tiêu chuẩn 3 trục chỉ có thể hoạt động theo các đường thẳng trên các mặt phẳng X, Y và Z, điều này khiến người vận hành phải dừng lại và di chuyển chi tiết nhiều lần để tiếp cận tất cả các bề mặt. Mỗi lần đặt lại vị trí, những sai lệch nhỏ trong căn chỉnh sẽ xảy ra. Các nghiên cứu cho thấy khoảng 70% các vấn đề đo lường nhỏ này xuất phát từ việc phải thiết lập lại nhiều lần như vậy theo thời gian. Một vấn đề khác là các dụng cụ cắt luôn ở vị trí cố định, do đó không phải lúc nào cũng cắt được ở góc tối ưu nhất. Điều này dẫn đến các bề mặt không đều và các chi tiết không giữ được hình dạng chính xác, đặc biệt là khi gia công các hình dạng phức tạp hoặc bề mặt cong, nơi mà độ chính xác đóng vai trò quan trọng nhất.

Máy CNC 5 trục đạt được độ chính xác dưới micromet như thế nào

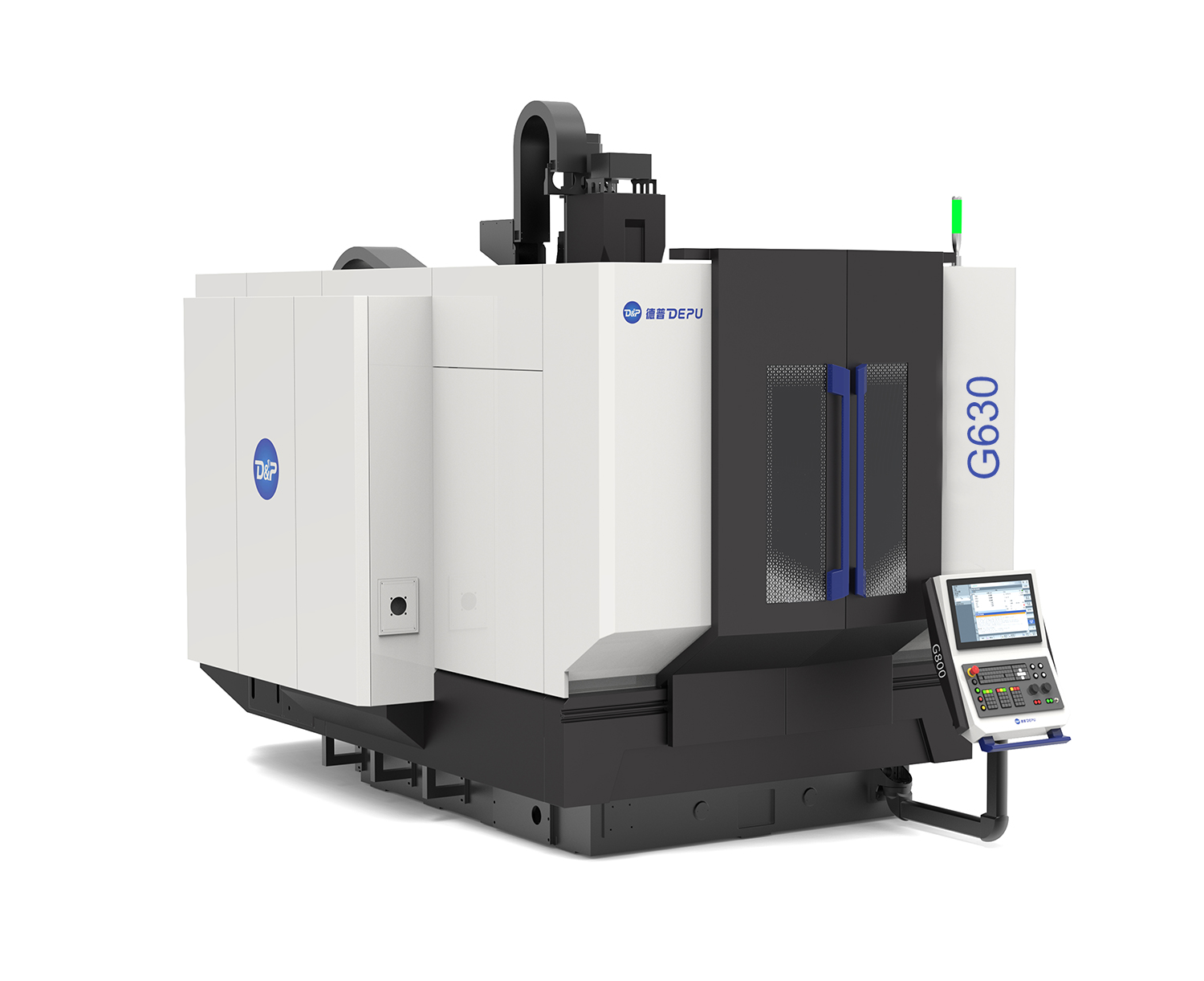

Máy CNC 5 trục hoạt động bằng cách di chuyển đồng thời theo ba đường thẳng (X, Y, Z) cộng thêm hai điểm xoay (có thể là A/B hoặc B/C). Cấu hình này giúp các bộ phận không cần phải tháo ra và thiết lập lại nhiều lần trong quá trình sản xuất. Những máy này được trang bị hệ thống phản hồi tinh vi sử dụng các bộ mã hóa cực kỳ chính xác. Chúng có thể phát hiện những thay đổi vị trí nhỏ tới khoảng 0,001 milimét và sau đó tự động điều chỉnh khi máy nóng lên hoặc công cụ bị mài mòn theo thời gian. Kết quả là độ chính xác gia công khoảng ±1 micrômét. Mức độ chính xác này rất quan trọng trong các ngành như sản xuất linh kiện quang học, chế tạo bán dẫn và sản xuất thiết bị y tế, nơi mà ngay cả những sai sót nhỏ cũng không thể chấp nhận được.

Ví dụ thực tế: Sản xuất các bộ phận y tế với dung sai ±0,001mm

Một nhà sản xuất lớn thiết bị cấy ghép phẫu thuật đã chứng kiến tỷ lệ bộ phận bị loại bỏ giảm gần một nửa khi họ chuyển sang gia công CNC 5 trục để chế tạo các đầu xương đùi bằng titan. Điểm khác biệt lớn nằm ở chỗ họ có thể hoàn thiện tất cả các chi tiết quan trọng chỉ trong một lần thiết lập máy duy nhất. Họ đã đạt được độ chính xác trong các phép đo hình cầu xuống còn khoảng 0,001 mm, mỏng hơn khoảng 70 lần so với độ dày trung bình của tóc người là khoảng 0,07 mm. Việc kiểm soát chặt chẽ các kích thước như vậy khiến các khớp ghép cấy vào cơ thể người khít hơn rất nhiều. Các thiết bị cấy ghép vừa vặn tốt hơn sẽ mang lại kết quả điều trị cải thiện cho bệnh nhân và tăng độ bền tổng thể của thiết bị.

Thực Hành Tốt Nhất: Hiệu Chuẩn Và Bảo Trì Để Đảm Bảo Độ Chính Xác Ổn Định

Để duy trì độ chính xác cấp micromet, việc hiệu chuẩn laser định kỳ (khuyến nghị 3 tháng/lần) và giám sát độ đảo trục chính là rất cần thiết. Các cơ sở sử dụng quy trình hiệu chuẩn hỗ trợ bởi AI báo cáo giảm 35% độ lệch kích thước hàng năm. Tuân thủ tiêu chuẩn ISO 230-2 để kiểm tra độ chính xác vị trí và thay thế các thanh trượt tuyến tính sau mỗi 8.000 giờ vận hành sẽ giúp ngăn ngừa sự suy giảm hiệu suất dần dần.

Gia Công Các Hình Học Phức Tạp Bằng máy cnc năm trục Tính linh hoạt

Thách Thức Của Các Bề Mặt Điêu Khắc Trên Hệ Thống 3 Trục Truyền Thống

Các máy CNC 3 trục tiêu chuẩn gặp khó khăn thực sự khi xử lý những hình dạng hữu cơ phức tạp mà chúng ta thấy trong các cánh tuabin hoặc các bộ phận cấy ghép y tế tùy chỉnh vì các đường chạy dao của chúng về cơ bản bị cố định và không thể tiếp cận dễ dàng các góc độ nhất định. Khi các nhà sản xuất muốn tạo ra các bề mặt cong phức tạp này, họ thường phải sử dụng nhiều lần thiết lập khác nhau trong suốt quá trình sản xuất, điều này khiến nguy cơ lệch lạc giữa các bước là rất rõ rệt. Các công cụ cũng không thể tiếp xúc đồng đều trên tất cả các bề mặt, dẫn đến chất lượng bề mặt kém và nhiều phế phẩm. Theo một số số liệu gần đây từ báo cáo Machining Insights 2024, các xưởng sử dụng hệ thống 3 trục truyền thống báo cáo lượng vật liệu phế thải nhiều hơn khoảng 23% so với những nơi đã chuyển sang sử dụng hệ thống đa trục. Sự khác biệt như vậy nhanh chóng trở nên đáng kể trên các dây chuyền sản xuất.

Chuyển động đồng thời đa trục cho phép thiết kế chi tiết phức tạp

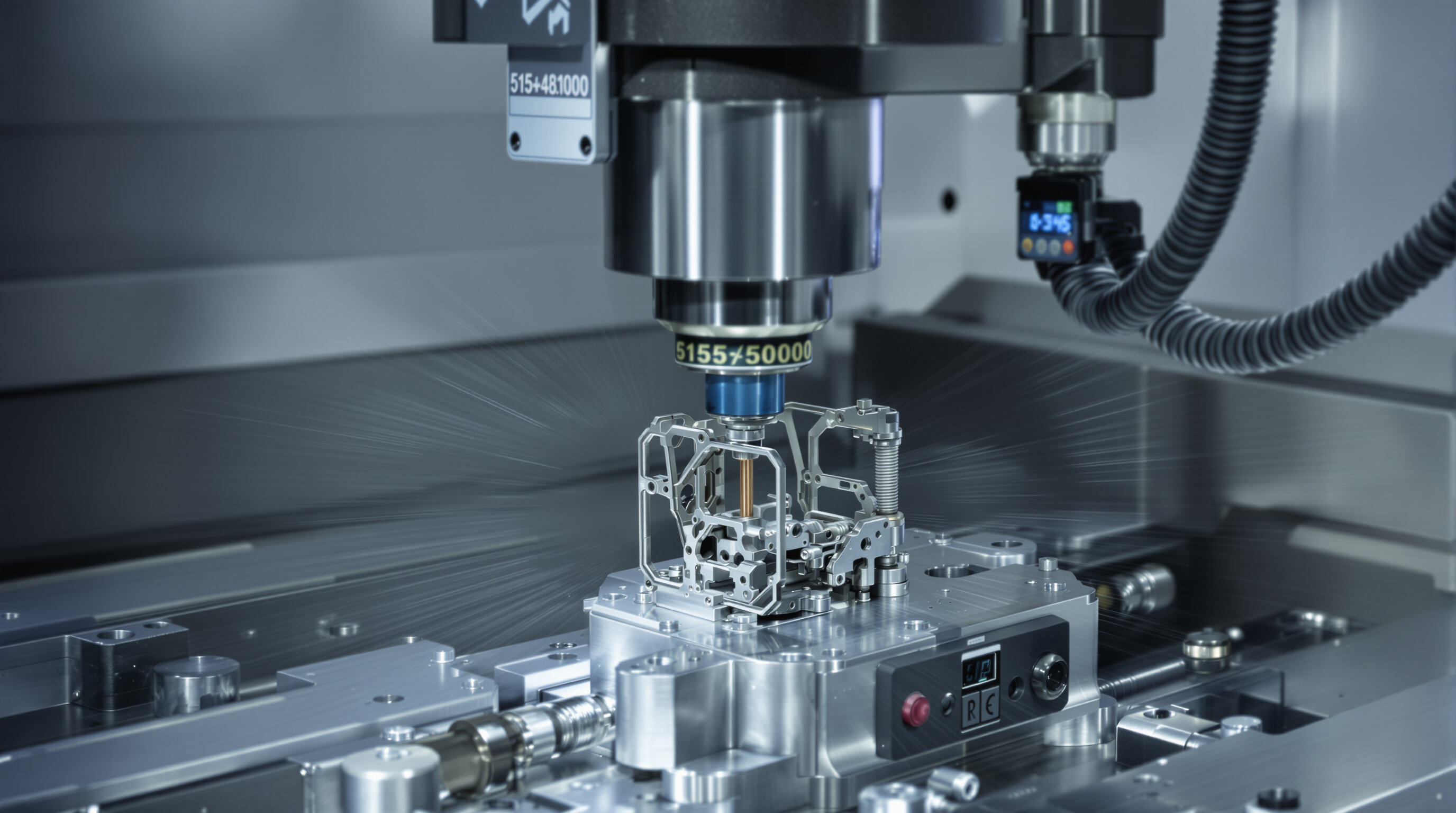

Với máy CNC 5 trục, cả dụng cụ cắt và phôi làm việc di chuyển xung quanh nhau trong quá trình vận hành, điều này giữ cho góc cắt luôn phù hợp ngay cả khi gia công các khoang sâu hay bề mặt cong phức tạp. Các nhà sản xuất hiện nay có thể thực sự tạo ra những bộ phận rất phức tạp, ví dụ như những vòi phun nhiên liệu bằng titan có cấu trúc tổ ong bên trong đòi hỏi độ chính xác cực kỳ cao với dung sai chỉ khoảng ±0,005 milimet. Một nghiên cứu gần đây từ ngành sản xuất hàng không vũ trụ vào năm 2025 cũng cho thấy một điều thú vị là những máy móc này giúp giảm thời gian chuẩn bị cho việc gia công các bộ phận phức tạp khoảng 40 phần trăm so với phương pháp truyền thống. Mức hiệu quả như vậy tạo ra sự khác biệt lớn trong các xưởng sản xuất nơi mà từng phút đều rất quý giá.

Nghiên cứu điển hình: Gia công cánh tuabin bằng công nghệ CNC 5 trục

Một công ty hàng đầu trong lĩnh vực năng lượng đã đạt được độ chính xác về kích thước 99,6% trong quá trình sản xuất cánh tuabin khí bằng công nghệ CNC 5 trục. Khả năng nghiêng trục B của máy đã loại bỏ việc phải định vị lại thủ công để tạo hình cánh quạt, giúp giảm thời gian chu kỳ cho mỗi cánh từ 8,5 giờ xuống còn 3,2 giờ. Độ đồng nhất bề mặt được cải thiện rõ rệt đến mức việc đánh bóng sau gia công cơ khí giảm tới 72%.

Tối Đa Hóa Tự Do Thiết Kế Với Sự Tích Hợp Giữa CAD/CAM

Các hệ thống 5 trục hiện đại ngày nay hoạt động cùng với các phần mềm CAD CAM để tạo ra các đường chạy dao cụ thể, tránh va chạm khi sản xuất các chi tiết phức tạp như bánh răng xoắn hoặc các thiết kế càng được tối ưu hóa thông qua phân tích hình thái. Trước khi bắt đầu cắt gọt thực tế, các nhà thiết kế có thể kiểm tra các hình dạng nhằm tối ưu hóa dòng chảy chất lỏng và xác minh xem chúng có thể được sản xuất thành công hay không. Theo ấn bản mới nhất của Tạp chí Advanced Manufacturing Quarterly năm 2024, phương pháp tiếp cận kỹ thuật số này đã mở ra khoảng 31% tùy chọn thiết kế bổ sung cho những người làm việc trong lĩnh vực ô tô và robot. Việc kiểm tra trước trên môi trường kỹ thuật số giúp tiết kiệm thời gian và nguyên vật liệu trong quá trình sản xuất sau này.

Giảm Thời Gian Chuẩn Bị và Hiệu Quả Một Lần Gá Trên Trục Duy Nhất phay cnc 5 trục

Những Khoảng Trễ Ẩn Trong Quy Trình Làm Việc 3 Trục Nhiều Giai Đoạn

gia công 3 trục thường đòi hỏi 4–5 lần định vị lại trên mỗi chi tiết, với mỗi lần thiết lập mất khoảng 15–30 phút để hiệu chỉnh và thay đổi đồ gá. Những hoạt động không liên quan đến cắt gọt này chiếm một phần đáng kể thời gian sản xuất—các nhà sản xuất ô tô cho biết rằng 64% thời gian giai đoạn được dùng cho việc định vị lại và các công việc liên quan.

Toàn Bộ Dải Gia Công 5 Trục Loại Bỏ Nhu Cầu Định Vị Lại

Với khả năng xoay trục A/B hoàn toàn, máy CNC 5 trục có thể tiếp cận năm mặt của phôi trong một lần kẹp duy nhất. Việc duy trì cùng một hệ tọa độ trong suốt quá trình gia công giúp loại bỏ sai số định vị tích lũy, vốn gây ra sai lệch chồng chất trong khoảng dung sai ±0,1–0,3mm ở các quy trình nhiều giai đoạn, từ đó nâng cao cả tốc độ và độ chính xác.

Cho Phép Sản Xuất Không Cần Can Thiệp Trực Tiếp Nhờ Ít Lần Thiết Lập Hơn

Bằng cách giảm 70% sự can thiệp của người vận hành, máy CNC 5 trục đạt được thời gian hoạt động liên tục 93–97% trong quá trình vận hành không người. Điều này hỗ trợ sản xuất các chi tiết phức tạp vào ban đêm, phù hợp với xu hướng của ngành công nghiệp—42% các nhà sản xuất hiện nay ưu tiên tự động hóa không cần ánh sáng, theo Khảo sát Công nghệ Sản xuất 2023.

Bề mặt hoàn thiện vượt trội thông qua góc công cụ tối ưu trên máy CNC 5 trục

Chất lượng bề mặt kém do tiếp xúc công cụ không tối ưu trong hệ thống 3 trục

Hướng công cụ cố định trong gia công 3 trục dẫn đến tiếp xúc không đồng đều trên các bề mặt cong, gây ra hiện tượng lượn sóng, rung lắc và mài mòn. Các công cụ thường hoạt động ở góc không hiệu quả, đặc biệt là trong các khoang sâu, dẫn đến độ lệch và bề mặt hoàn thiện không đồng đều. Những khuyết điểm này làm tăng 30–40% thời gian hoàn thiện thủ công đối với các bộ phận phức tạp.

Duy trì tiếp xúc công cụ vuông góc với máy CNC 5 trục

Trong gia công 5 trục, hệ thống thay đổi góc độ của dụng cụ cắt thông qua hai trục phụ A và B để luôn giữ góc vuông với bất kỳ bề mặt nào đang được gia công. Cách thức hoạt động của phương pháp phay mặt bên này giúp phân bố lực đều trên toàn bộ chiều rộng của dụng cụ cắt, làm giảm lực tác động khoảng hai phần ba. Khi dụng cụ cắt duy trì liên tục góc 90 độ vuông góc với vật liệu, độ rung trong quá trình vận hành sẽ giảm xuống. Điều đó có nghĩa là các kỹ sư vận hành có thể gia công mạnh mẽ hơn với tốc độ chạy dao nhanh hơn, đồng thời vẫn đạt được chất lượng bề mặt tốt hơn, đặc biệt khi gia công các vật liệu cứng được tôi nhiệt hay tôi bề mặt.

Ứng dụng Hàng không: Đạt được bề mặt hoàn thiện như gương

Trong sản xuất cánh tuabin, gia công CNC 5 trục mang lại độ nhẵn bề mặt đạt Ra 0.2–0.4 μm mà không cần đánh bóng thủ công. Bằng cách kết hợp độ nghiêng trục chính với việc cắt viền tốc độ cao, các đường chạy dao trở nên vô hình trên các bề mặt nhạy cảm về khí động học. Các bề mặt tiếp giáp tại gốc cánh đáp ứng các yêu cầu về độ phẳng bề mặt của FAA (±0.001mm) thông qua góc công cụ chính xác và tối ưu hóa việc loại bỏ phoi.

Giảm thiểu khoảng dịch chuyển và dấu vết dụng cụ bằng chức năng nghiêng

Điều khiển đồng thời các trục giảm khoảng cách dịch chuyển bước (stepover) tới 50–75% so với phương pháp 3 trục. Các vector nghiêng có thể lập trình đảm bảo chuyển tiếp mượt mà giữa các bề mặt với khoảng bước đồng đều. Việc loại bỏ thao tác định vị lại giúp tránh các đường phân cách và dấu vết dụng cụ chồng lấn, trong khi lập kế hoạch đường chạy dao thông minh sẽ hướng các chuyển động thoát dao ra khỏi các vùng thẩm mỹ quan trọng.

Tăng năng suất và hiệu quả chi phí dài hạn phay cnc 5 trục

Quy trình gia công 3 trục truyền thống đi kèm với rất nhiều chi phí ẩn mà ngày nay ít ai còn nhắc đến. Hãy nghĩ đến những lần thiết lập lại lặp đi lặp lại, nhu cầu phải sử dụng các đồ gá đặc biệt, cùng với việc phải giám sát trực tiếp liên tục. Đối với các xưởng sản xuất vừa, khoảng 18 phần trăm thời gian sản xuất thực tế bị mất đi chỉ vì họ phải liên tục di chuyển các bộ phận giữa các công đoạn. Đây chính là lúc gia công CNC 5 trục thay đổi cục diện. Khi các công ty chuyển sang công nghệ này, họ có thể thực hiện nhiều công đoạn cùng lúc mà không cần phải thiết lập lại liên tục. Chi phí nhân công cũng giảm đáng kể vì nhu cầu sử dụng các công cụ chuyên dụng ít hơn. Một số nhà sản xuất phụ tùng ô tô làm việc trên hộp số báo cáo rằng họ đã giảm được gần hai phần ba chu kỳ sản xuất chỉ bằng cách loại bỏ những lần dừng làm phiền phức để định vị lại đó.

Các nhà sản xuất có tầm nhìn tương lai kết hợp máy cnc năm trục với tối ưu hóa đường chạy dao điều khiển bằng AI để giảm mức tiêu thụ năng lượng tới 22% và kéo dài tuổi thọ dụng cụ. Chiến lược tích hợp này làm giảm chi phí trên mỗi sản phẩm tới 31% trong suốt vòng đời thiết bị năm năm, giúp công nghệ 5 trục trở nên hiệu quả về mặt kinh tế ngay cả đối với sản xuất với số lượng thấp nhưng độ chính xác cao.

Mục Lục

- Độ chính xác vượt trội và dung sai chặt chẽ hơn với máy cnc năm trục

- Gia Công Các Hình Học Phức Tạp Bằng máy cnc năm trục Tính linh hoạt

- Giảm Thời Gian Chuẩn Bị và Hiệu Quả Một Lần Gá Trên Trục Duy Nhất phay cnc 5 trục

- Những Khoảng Trễ Ẩn Trong Quy Trình Làm Việc 3 Trục Nhiều Giai Đoạn

- Toàn Bộ Dải Gia Công 5 Trục Loại Bỏ Nhu Cầu Định Vị Lại

- Cho Phép Sản Xuất Không Cần Can Thiệp Trực Tiếp Nhờ Ít Lần Thiết Lập Hơn

- Bề mặt hoàn thiện vượt trội thông qua góc công cụ tối ưu trên máy CNC 5 trục

- Tăng năng suất và hiệu quả chi phí dài hạn phay cnc 5 trục