Rotary Table vs. Trunnion: Choosing the Right 5-Axis Configuration

Introduction

When selecting a 5-axis CNC machine, most manufacturers focus on spindle power, travels, or control systems. However, the 5-axis configuration itself—rotary table vs. trunnion—often has a greater impact on machining accuracy, rigidity, and process stability than the machine’s headline specifications.

Both rotary table and trunnion designs enable simultaneous 5-axis machining, but they differ significantly in kinematic structure, load capacity, dynamic behavior, and suitability for complex parts manufacturing. Choosing the wrong configuration can lead to vibration issues, premature wear, limited part size, or compromised surface quality—especially in aerospace, energy, and heavy-duty applications.

This article breaks down the key structural, mechanical, and application-level differences between rotary table and trunnion 5-axis CNC machines to help you select the right solution for your production needs.

Understanding the Two 5-Axis Configurations

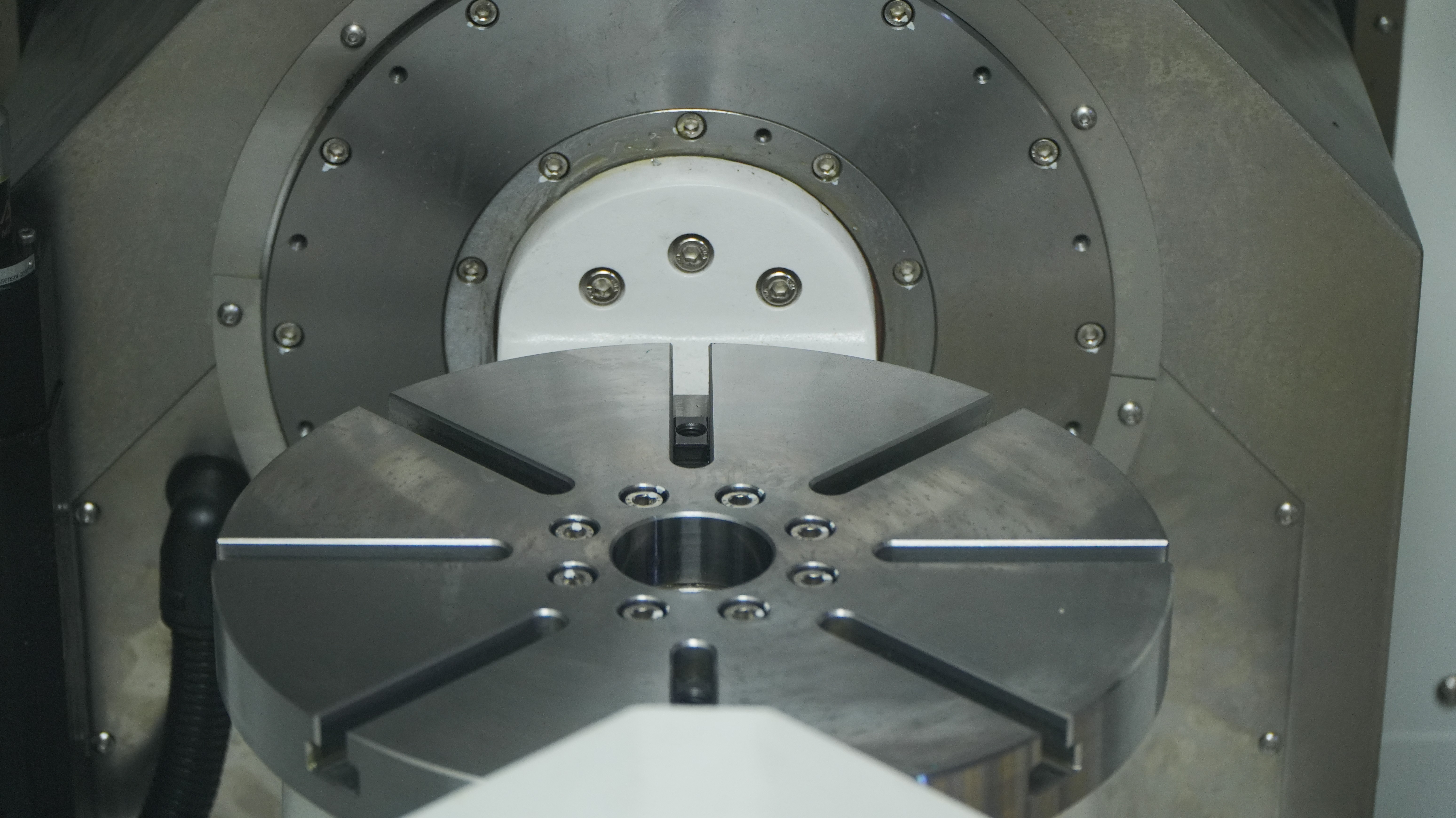

What Is a Rotary Table 5-Axis Configuration?

A rotary table configuration typically uses:

-

Three linear axes (X, Y, Z)

-

Two rotary axes integrated into the table (A/B or C)

In this setup, the workpiece rotates while the spindle remains relatively fixed in orientation. Rotary tables are often compact, making them popular for small to medium-sized parts that require high positional accuracy.

Key characteristics:

-

Short kinematic chain

-

Lower moving mass

-

High positioning precision

-

Limited load capacity depending on table size

What Is a Trunnion 5-Axis Configuration?

A trunnion configuration mounts the workpiece on a tilting cradle (trunnion) that rotates around one axis and tilts around another, usually combined with linear X/Y/Z motion.

In contrast to a rotary table, the workpiece is supported by a larger mechanical structure, designed to handle higher loads and longer machining cycles.

Key characteristics:

-

Higher rigidity under load

-

Better support for large or heavy parts

-

Longer kinematic chain

-

Slightly higher complexity in calibration and compensation

Rotary Table vs. Trunnion: Structural Comparison

1. Load Capacity and Rigidity

One of the most important differences between rotary table vs. trunnion designs is how they handle mass.

Rotary table machines are ideal for lightweight, high-precision components such as medical implants or 3C parts. However, when part weight increases, table bearings and torque motors can become limiting factors.

Trunnion-based 5-axis CNC machines are inherently more rigid. Their structural design distributes load through the cradle and base, making them far more suitable for aerospace components, engine housings, and large structural parts.

In heavy-duty machining, trunnion configurations consistently outperform rotary tables in long-term stability.

2. Accuracy and Kinematic Stability

Accuracy in 5-axis CNC machining is heavily influenced by kinematic consistency over time.

Rotary tables benefit from:

-

Fewer moving components

-

Shorter error propagation paths

-

Excellent positioning accuracy in small envelopes

However, under continuous high-load cutting, thermal growth and bearing stress can degrade long-term accuracy.

Trunnion machines, while requiring more advanced kinematic compensation, maintain better volumetric accuracy under load, especially during extended machining cycles common in aerospace manufacturing.

3. Machining Envelope and Accessibility

Rotary table machines typically offer:

-

Compact footprints

-

Efficient tool access for small parts

-

Faster indexing movements

Trunnion configurations provide:

-

Larger effective machining envelopes

-

Better clearance for long tools

-

Greater flexibility for complex, multi-face machining

For parts requiring deep cavities, long tools, or multiple angular approaches, trunnion designs reduce collision risk and improve tool life.

Application-Based Selection Guide

When a Rotary Table Makes Sense

Choose a rotary table 5-axis CNC machine if:

-

Parts are small to medium in size

-

High positional accuracy is the top priority

-

Cutting forces are relatively low

-

Cycle times are short and repeatable

Typical industries include:

-

Medical devices

-

Electronics

-

Precision molds

-

Small aluminum components

When a Trunnion Is the Better Choice

A trunnion configuration is the right solution when:

-

Parts are large, heavy, or unbalanced

-

High cutting forces are involved

-

Long machining cycles are required

-

Structural rigidity and stability are critical

This is why aerospace, energy, automotive, and heavy equipment manufacturers overwhelmingly favor trunnion-based 5-axis machines.

Cost Considerations Beyond the Machine Price

While rotary table machines often appear more affordable initially, the true cost comparison between rotary table vs. trunnion should include:

-

Tool wear and breakage

-

Scrap rates

-

Recalibration frequency

-

Long-term accuracy retention

In high-load environments, trunnion machines frequently deliver lower total cost of ownership despite higher upfront investment.

FAQ

1. Is a rotary table or trunnion more accurate?

Both can achieve high accuracy, but rotary tables excel in lightweight precision work, while trunnions maintain accuracy better under heavy loads and long machining cycles.

2. Which 5-axis configuration is better for aerospace parts?

Trunnion-based 5-axis CNC machines are generally preferred for aerospace due to superior rigidity, load capacity, and long-term stability.

3. Does a trunnion machine require more maintenance?

Trunnion machines involve more complex kinematics, but modern compensation systems minimize maintenance differences when properly calibrated.

4. Can rotary table machines handle steel or titanium?

They can, but only for smaller parts. For sustained cutting in steel or titanium, trunnion configurations are typically more reliable.