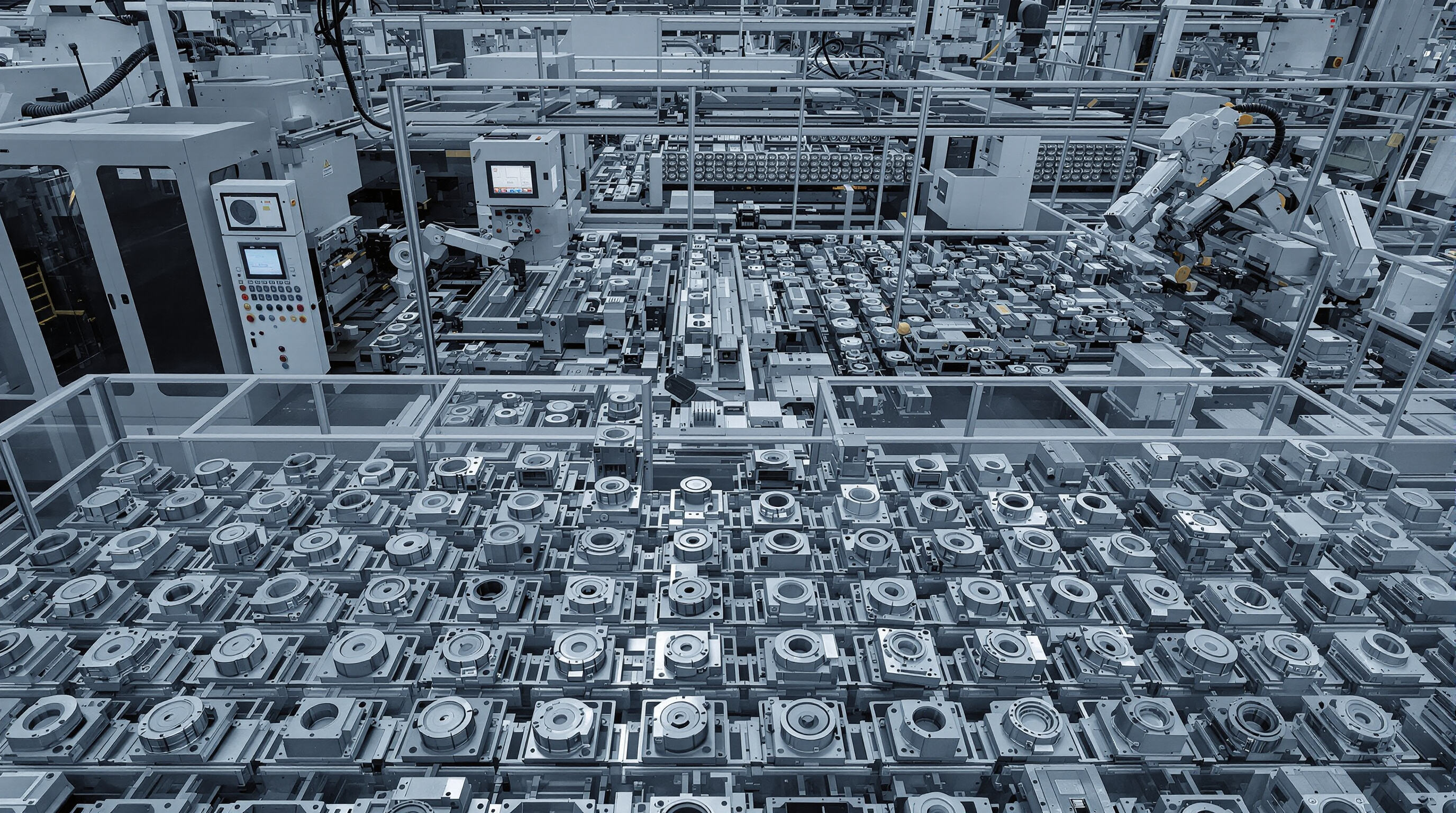

Atingerea unei precizii fără concurenți și a toleranțelor strânse cu Mașini CNC

Mașinile CNC moderne ating toleranțele de ±0,001 inci, fiind indispensabile pentru industrii precum aviația și fabricarea dispozitivelor medicale. Acest nivel de precizie asigură componentele se potrivesc perfect în medii cu solicitări mari, minimizând deșeurile și costurile de refacere.

Înțelegerea preciziei în Frezare CNC și controlul toleranțelor

Precizia în prelucrarea CNC se referă la capacitatea unei mașini de a repeta aceleași măsurători identice în mod repetat, iar toleranța definește abaterea permisă față de specificațiile proiectului. Controlul strâns al toleranțelor (ajungând la ±0,0002" în aplicații avansate) depinde de patru factori critici:

- Prelucrarea cu mai multe axe eliminarea erorilor de reașezare manuală în geometrii complexe

- Optimizarea traseului sculei software-ul CAM calculează unghiurile și vitezele exacte de tăiere

- Compensare termică compensarea dilatării metalului în timpul operațiunilor prelungite

- Metrologie în timp real senzorii în proces detectează abaterile la nivel de microni

Aceste strategii reduc variația dimensională cu 37% comparativ cu metodele convenționale (Institutul de Prelucrare Precisă, 2023).

Cum tehnologia CNC asigură o precizie constantă pentru piesele complexe

mânașele CNC cu 5 axe permit prelucrarea într-un singur set-up a componentelor complexe, cum ar fi paletele de turbină, menținând o precizie pozițională de 5 microni. Producția roților dințate elicoidale realizează profile aproape perfecte ale dinților (99,8% consistență pe un lot de 10.000 de unități) prin utilizarea sistemelor de control servo cu buclă închisă. Aceasta elimină erorile de măsurare manuale care au cauzat în mod tradițional un procent de rebut de 12–15% în fabricarea roților dințate.

Calibrare avansată și sisteme cu feedback în timp real în echipamentele moderne Mașini CNC

Sistemele CNC de generația a treia integrează:

| TEHNOCOGNOSTICĂ | Funcție | Îmbunătățirea Preciziei |

|---|---|---|

| Setere laser ale sculelor | Măsoară uzura sculei cu o rezoluție de 0,05µm | 22% |

| Reductoare de Vibrații | Reduce defectele de suprafață induse de vibrații | 18% |

| Control adaptiv al arborelui principal | Ajustează automat turația în funcție de sarcină | 15% |

Aceste sisteme efectuează 120–180 de verificări de calibrare pe oră, depășind cu mult cele 25–30 de verificări manuale posibile cu mașinile tradiționale.

Studiu de caz: Creșterea preciziei în componentele aeronautice

Un proiect recent din industria aerospațială, realizat cu un important producător de echipamente CNC, a demonstrat:

- reducere cu 42% în ceea ce privește variația dimensională a componentelor longeronului aripii

- 0.009 mm abatere medie la 2.000 carcase pentru valve de combustibil

- randament de 98,7% la prima trecere prin utilizarea sondajului automat în timpul ciclului

Această precizie permite asamblarea directă a pieselor realizate prin prelucrare CNC, fără prelucrare ulterioară, reducând timpii de producție cu 34%.

Creșterea eficienței prin automatizare și integrarea CAD/CAM

Cum automatizarea în Frezare CNC Reducerea timpilor de ciclu și creșterea producției

Automatizarea CNC elimină ajustările manuale ale sculelor și manipularea materialului, reducând ciclurile de producție cu 35–50% în cazul producțiilor de volum mare. Capacitățile de operare continue permit prelucrarea 24/7 fără scăderi de calitate legate de oboseală, iar sistemele de detectare a coliziunilor previn erorile costisitoare în timpul schimbărilor neasistate.

Rolul software-ului CAD/CAM în activarea unor designuri complexe, repetabile și fără erori

Sistemele integrate CAD (Computer-Aided Design) și CAM (Computer-Aided Manufacturing) transformă planurile digitale în instrucțiuni de prelucrare cu o precizie de poziționare de 0,005 mm. O analiză din 2025 a industriei a arătat cu 85% mai puține discrepanțe geometrice comparativ cu introducerea manuală a codurilor G. Simulările avansate de traseu al sculei detectează punctele de stres ale materialului înainte de începerea tăierii, reducând ratele de rebut cu 22% în cazul componentelor complexe din industria aerospațială.

Schimbarea automată a sculelor și operarea continuă pentru cicluri de producție mai rapide

Centrele CNC moderne cu magazine de 60+ scule realizează schimbări complete în mai puțin de 15 secunde, comparativ cu 8–12 minute în configurațiile manuale. Acest lucru permite producția de loturi mixte fără întreruperi — un factor esențial în atingerea unui nivel de utilizare a echipamentelor de 92%, conform standardelor de producție lean.

Asigurarea Consistenței și Repetabilității în Producția de Mare Serie

Cum Frezare CNC Păstrează Uniformitatea Pieselor pe Loturi Mari

Mâșinile cu comandă numerică computerizată oferă o consistență remarcabilă la nivel microscopic, deoarece urmează trasee preprogramate, în loc să se bazeze pe operatori umani care ar putea comite mici greșeli. Conform unui studiu publicat anul trecut de ASME, aceste sisteme avansate pot menține măsurătorile în limitele de plus-minus 0,002 milimetri pe parcursul unor serii de producție mari, uneori depășind 50.000 de piese. Tehnicile tradiționale de fabricație pur și simplu nu pot egala această repetabilitate. În privința operațiunilor precum adâncimea la care sunt frezate găurile sau unghiul suprafețelor prelucrate, totul urmează strict specificațiile digitale. Rezultatul? Piese identice, indiferent dacă vorbim de fabricarea a o sută de produse sau sute de mii. Pentru producătorii de automobile, acest aspect este deosebit de important. Imaginați-vă că o componentă minusculă undeva în linia de asamblare a vehiculelor nu respectă specificațiile. Acest lucru ar putea cauza probleme majore pe termen lung, atunci când mașinile ajung pe drumuri.

Reducerea variabilității în producția de masă prin controlul digital al procesului

Sistemele CNC moderne sunt echipate cu senzori în timp real care monitorizează peste 18 factori diferiți, precum nivelul de căldură, vibrațiile mașinii și gradul de uzură al sculelor în timpul funcționării. Datele privind controlul calității arată ceva destul de impresionant: aceste mașini pot ajusta automat pozițiile sculelor într-un interval de doar 0,8 secunde după detectarea unei probleme, ceea ce le face de aproximativ doisprezece ori mai rapide la corecții comparativ cu ceea ce omul ar putea realiza manual. Aceste sisteme cu buclă închisă de feedback își modifică efectiv parametrii de tăiere de la un ciclu de producție la altul, reducând deșeurile cu până la 34% în cazul loturilor mari, conform unui studiu publicat în Journal of Manufacturing Systems încă din 2023. În practică, acest lucru înseamnă că chiar și cele mai complicate forme rămân într-o toleranță de sub 10 microni pe durata a luni întregi de producție neîntreruptă, fără o degradare semnificativă a calității.

Reducerea Costurilor cu Forța de Muncă și a Erorilor Umane Prin Automatizarea CNC

Minimizarea erorilor umane prin operarea programată a mașinilor CNC

Mașinile cu comandă numerică computerizată (CNC) elimină practic erorile manuale de măsurare și problemele de aliniere la tăiere, deoarece urmează instrucțiuni programate cu o precizie de aproximativ 0,005 mm de fiecare dată. Datele statistice sunt destul de impresionante și în ceea ce privește reducerea greșelilor făcute de oameni în timpul lucrărilor de frezare. Unele cercetări din domeniu arată o scădere cu aproximativ 90% a acestui tip de probleme după implementarea tehnologiei CNC. Ce se întâmplă în continuare este că operatorii nu mai petrec întreaga zi făcând ajustări manuale. În schimb, ei supraveghează simultan mai multe mașini, lăsând sistemele automate să se ocupe de părțile complexe. Dispozitive precum sonde ale arborelui principal care se corectează singure și unelte laser care stabilesc automat pozițiile preiau sarcinile care înainte reprezentau o adevărată bătaie de cap pentru muncitorii din prelucrare.

Economii pe termen lung privind costurile cu forța de muncă, în ciuda investiției inițiale mai mari în tehnologie CNC

Sistemele CNC costă cu siguranță mai mult inițial comparativ cu mașinile manuale, în medie cu 30 până la 50 la sută mai mult. Totuși, mulți producători constată că facturile lor cu forța de muncă scad semnificativ în timp, uneori chiar cu aproximativ 60 la sută mai mici după cinci ani. Motivul? Schimbătoare automate de paleți și roboți care se ocupă de piese permit fabricilor să funcționeze ziua și noaptea cu mult mai puțini angajați. Vorbim de faptul că este nevoie doar de o singură persoană tehnician care să supravegheze șase mașini diferite simultan. Atunci când companiile gestionează volume mari de comenzi, aceste economii devin semnificative. Costurile cu forța de muncă pe unitatea de produs scad între 40% și aproape 60% în unele cazuri. Majoritatea firmelor constată că aceste economii acoperă costurile inițiale de investiție în aproximativ 18 luni, mai-mai puțin, în funcție de gradul de activitate.

Echilibrarea costurilor inițiale cu ROI-ul operațional în adoptarea CNC

Sistemele CNC moderne obțin un ROI complet în 2–3 ani prin trei avantaje strategice:

- 68% timpuri de pregătire mai rapide cu biblioteci de unelte digitale vs. calibrare manuală

- reducere cu 45% a materialelor de rebut prin detectarea imediată a erorilor

- utilizare a mașinii cu 22% mai mare prin capacități de producție fără supraveghere umană

Aceste eficiențe permit producătorilor de serii mici să-și amortizeze investițiile în CNC-uri la 1.200 de piese anuale, în timp ce întreprinderile mari obțin randamente accelerate odată cu creșterea producției.

Creșterea flexibilă a producției cu sisteme CNC modulare și scalabile

Cerințele actuale ale fabricației necesită sisteme CNC care să se adapteze nevoilor schimbătoare de producție, fără reabilitări costisitoare. Configurațiile modulare CNC permit producătorilor să-și mărească capacitatea cu peste 70% în perioadele de vârf ale cererii, menținând în același timp precizia – un avantaj esențial pentru industrii precum aviația și automobilele, care se confruntă cu volume volatile de comenzi.

Adaptarea configurațiilor CNC pentru a satisface cerințele crescânde și în continuă schimbare ale fabricației

Liniile tradiționale de producție sunt destul de inflexibile atunci când vine vorba de modificarea pieselor sau materialelor, însă sistemele CNC modulare povestesc o altă poveste. Aceste sisteme pot fi reconfigurate rapid pentru o multitudine de geometrii și tipuri de materiale noi. Interfețele de schimb rapid ale dispozitivelor de prindere joacă un rol minunat aici, la fel ca și capabilitățile multi-ax care reduc semnificativ timpul de pregătire. Ceea ce înainte dura ore acum durează doar câteva minute, astfel încât companiile pot trece ușor între producția de prototipuri și trecerea la producție la scară completă în aceeași zi. Să luăm, de exemplu, producătorii de componente pentru baterii de vehicule electrice. Ei se bazează în mare măsură pe aceste celule CNC reconfigurabile, deoarece proiectele lor se dezvoltă în mod constant. Prin această flexibilitate, nu trebuie să oprească întreaga activitate doar pentru a face ajustări în fluxul lor de lucru.

Configurații CNC modulare pentru linii de producție agile și pregătite pentru viitor

Scalabilitatea depinde de interfețele standardizate și de sistemele de control centralizate care unifică mașinile CNC diferite. Configurațiile moderne integrează:

| Caracteristică | CNC tradițional | CNC modular |

|---|---|---|

| Modificări la configurare | Ore/zile | <25 de minute (UCAM 2024) |

| Scalare a capacității | Infrastructură fixă | gestionare a creșterilor bruște de peste 70% |

| Eficienţă în ceea ce priveşte costurile | Costuri ridicate inițial | Investiție incrementală |

Această agilitate permite producătorilor să implementeze sisteme hibride – combinând module de frezare, strunjire și fabricație aditivă – pentru a-și proteja operațiunile împotriva schimbărilor neașteptate ale produselor. Unitățile care adoptă aceste strategii raportează timpi de reacție la schimbările de piață cu 40% mai rapizi comparativ cu liniile CNC fixe (Precision Machining Journal, 2023).

Întrebări frecvente

Ce este precizia în prelucrarea CNC?

Precizia în prelucrarea CNC se referă la capacitatea mașinii de a produce componente cu o reproductibilitate exactă conform măsurilor specificate, asigurând o calitate și funcționalitate constantă.

Cum mențin mașinile CNC consistența în producția de masă?

Mașinile CNC mențin consistența prin trasee preprogramate, care minimizează erorile umane, și prin monitorizare în timp real cu senzori care ajustează variațiile apărute în timpul producției.

Care sunt beneficiile utilizării sistemelor CNC modulare?

Sistemele CNC modulare oferă flexibilitatea de a reconfigura setările rapid pentru diferite piese și materiale, permițând producătorilor să se adapteze eficient la cerințele în continuă schimbare ale pieței.

Pot mașinile CNC reduce costurile cu forța de muncă?

Da, deși mașinile CNC au un cost inițial mai mare, ele reduc semnificativ costurile cu forța de muncă pe termen lung prin minimizarea ajustărilor manuale și permițând operatorilor să supravegheze simultan mai multe mașini.

Care sunt avantajele integrării CAD/CAM în prelucrarea CNC?

Integrarea CAD/CAM permite conversia precisă a designurilor digitale în instrucțiuni pentru mașini, creșterea preciziei și reducerea ratei erorilor și a rebuturilor în procesele complexe de fabricație.

Cuprins

- Atingerea unei precizii fără concurenți și a toleranțelor strânse cu Mașini CNC

- Creșterea eficienței prin automatizare și integrarea CAD/CAM

- Asigurarea Consistenței și Repetabilității în Producția de Mare Serie

- Reducerea Costurilor cu Forța de Muncă și a Erorilor Umane Prin Automatizarea CNC

- Creșterea flexibilă a producției cu sisteme CNC modulare și scalabile

- Întrebări frecvente